Sheet metal bending machine equipment is the basic equipment of sheet metal processing industry, which occupies an important position in the field of forming metal product .Domestic metal cutting machine in the sheet metal previous process has been basically automated,while the vast majority of bending equipment in the sheet metal field is still traditional equipment,which has low degree of automation, low efficiency, and high technical requirements for practitioners.According to the statistics,the global market stock of sheet metal machine tool is more than 500,000 sets,market scale is over 100 billion.The total annual demand is more than 100,000 sets. Among them, the annual demand for Panel Bender Machine is more than 20,000.

Compared with traditional bending machine, the main advantages of Panel Bender Machine are as follows:

1. Speed

The bending process of Panel Bender Machine is fully automated up to 0.2 seconds/cut,greatly reduced multilateral and multi-channel bending cycle time, is more than 3 times the speed of the traditional CNC bending machine.It is more than 3 times the speed of the traditional CNC bending machine.The more hem the workpiece has and more complex it is, the greater speed advantage the Panel Bender Machine has .Traditional CNC bending machine needs technical workers to hold the workpiece to position and bend, each fold needs to be repositioned, which has low efficiency.

The bending process of Panel Bender Machine is fully automated up to 0.2 seconds/cut,greatly reduced multilateral and multi-channel bending cycle time, is more than 3 times the speed of the traditional CNC bending machine.It is more than 3 times the speed of the traditional CNC bending machine.The more hem the workpiece has and more complex it is, the greater speed advantage the Panel Bender Machine has .Traditional CNC bending machine needs technical workers to hold the workpiece to position and bend, each fold needs to be repositioned, which has low efficiency.

2. Manual work

The technical requirements of the workers to operate Panel Bender Machine are low.Ordinary workers can be trained to work, don’t need to hire experienced skilled workers.At the same time, the bending process is completely automatic, greatly saving labor and reducing the labor intensity of workers.

For large size of the workpiece,traditional CNC bending machine often needs more than one person to finish bending process.While using Panel Bender Machine, workers only need to place the workpiece to the workbench, the equipment automatically complete the positioning, which is the real sense of time and labor saving.

3. Safety

Panel Bender Machine doesn’t need to hold the workpiece in hand, bending process is completely automatic, greatly reducing safety risks of workers due to misoperation .

4. Usability

Panel Bender Machine uses graphic visual programming,workers only need to input bending data according to the workpiece, the system automatically generates bending instructions, without the use of code programming, which ordinary workers can master in 2 hours.

Traditional CNC bending machine requires workers to master complex programming skills, and to memorize the bending order of each fold in the bending process , which is difficult and easy to make a mistake.

5. Consistency

Panel Bender Machine can realize the automatic positioning of the plate, the positioning accuracy of the system can reach to 0.001mm, the consistency of the product after forming is higher and more suitable for mass production.

The traditional CNC bending machine’s positioning is not precise, the size error will be caused due to multiple positioning.

6. Automation

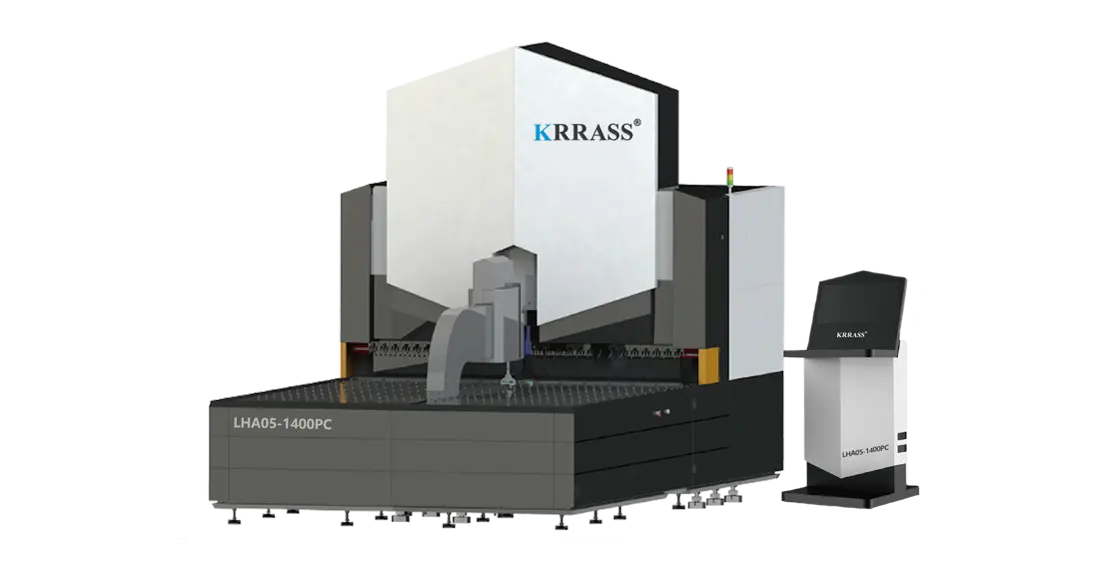

KRRASS Panel Bender Machine reserves a wealth of interfaces to facilitate the docking of upstream and downstream production lines,can butt mechanical arm to realize automatic integrated loading and unloading.

KRRASS self-drive manipulator is equipped with the same control system as KRRASS Panel Bender Machine, which has higher collaborative efficiency.There is no need to maintain two sets of procedures to replace the workpiece, only need to change the bending center program, automatic generation of mechanical arm program and has higher flexibility.

7. System upgrade

KRRASS Panel Bender Machine is completely independent research and development, has a number of core technology patents, lifetime free upgrade, the system reserved rich interface in accordance with Industry 4.0 architecture.

8. Mold

Panel Bender Machine adopts universal bending mold and the bending of various shapes is realized by multi - axis concurrent linkage servo control.The traditional CNC bending machine needs a mold each bending process,it needs to customize special mold for each shape and the cost is higher for each shape.

KRRASS: the best choice for

all sheet metal processing manufacturers

When considering the overall costs of purchasing, maintaining, and operating a sheet metal equipment setup, a sheet metal fabrication service: KRRASS brand is your best choice. KRRASS has a tremendous reputation in the market due to its focus on consistency and quality at the most competitive price.

Whether it's Panel Bender Machine or any other application equipment, our team of experts has the right combination of industry knowledge and the latest tool to provide you with the best products and services on the market. Moreover, we set ourselves apart with our advanced system that is completely online. Just let us know what your product needs, request a quote, and start the process.

Make a request and Get Started Today

Get Instant Quote

Learn more about our products, please visit and subscribe to our Youtube channel