KRRASS designed the plasma-oxygen carbon steel cutting machine using modern construction and mechanics solutions. They ensured the best efficiency and an attractive, innovative look. Modified bridge construction makes it more rigid and resistant to high temperatures. It is essential, especially during even 300 mm thick materials cutting. The unique combination of safety systems used in plasma-oxygen carbon steel cutting machines ensures the highest comfort and the best level of safety for machine operators and the people around them.

The cutting table is also structurally independent from the machine, which is ideal for loading heavy plates since accidental shocks will not affect the performance.

A unique safety system, with an assigned perimeter and an emergency stop, stops the machine instantly in the event of a collision to protect the safety of your operators.

A unique safety system, with an assigned perimeter and an emergency stop, stops the machine instantly in the event of a collision to protect the safety of your operators.

| P-Series Plasma Cutting | Cutting Width | Cutting Length | Table Height | Height | Width | Length | Width (Including Power Unit) | Length (Including Filter) | Filter Height | Filter Length | |

| A | B | C | D | E | F | G | H | I | J | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | ||

| A1500 | 3000 | 1500 | 3100 | 650 | 2000 | 2320 | 4500 | 5500 | 6500 | 2200 | 2000 |

| 4000 | 1500 | 4100 | 650 | 2000 | 2320 | 5500 | 6000 | 7500 | 2200 | 2000 | |

| 6000 | 1500 | 6100 | 650 | 2000 | 2320 | 7500 | 6000 | 10000 | 2200 | 2500 | |

| A2000 | 6000 | 2000 | 6100 | 650 | 2000 | 2820 | 7500 | 6500 | 10000 | 2200 | 2500 |

High productivity, low operating cost, high cutting speed, long life and exceptional cutting quality. Offers wide range cutting from very thin sheet thickness to very thick sheet thickness.

Thanks to its easy operation, plasma processes can be efficiently and easily managed.

Efficiency, fast cutting, fast processing cycle provides high reliability with easy replacement of consumables. Advantages: Superior cutting quality, minimum operating cost and maximum productivity.

High precision cutting achieved with dual guiding system Rack Pinion and Linear Guides.

Cable channels in accordance with CE standards, silent operation, durability, With its anti-friction and non-breaking properties usage life is much longer.

With the PLC software, pneumaticly controlled hatches which are only at the cutting area are opened. With this way more powerful suction with less energy consumption can be achieved.

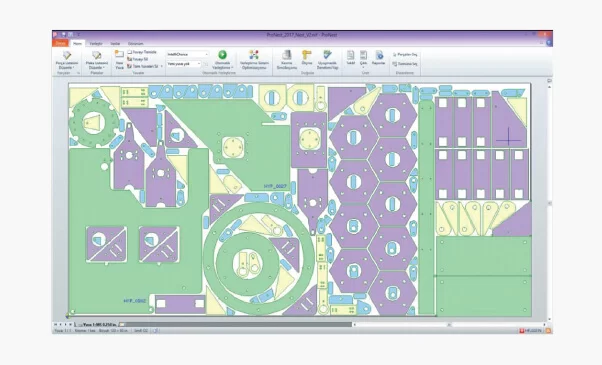

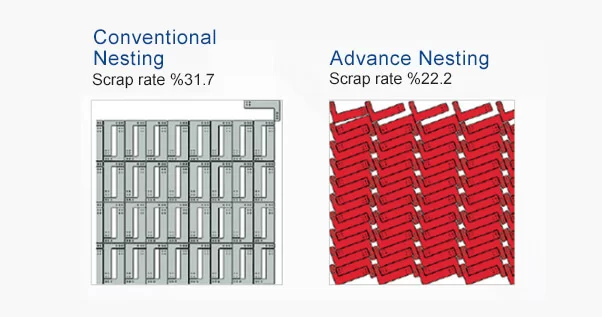

EDGE® Connect, Hypertherm’s newest Computer Numeric Control (CNC) plat- form, delivers unmatched reliability, powerful embedded capabilities, and a high level of customizability. Based on our proprietary, industry-leading Pho- enix® CNC platform, the system offers new, advanced software features – inc- luding ProNest® CNC automatic nesting delivering SureCutTM technology – along with enhanced hardware. For easy set up, changes, and upgrades, EDGE Connect CNCs can be configu- red in the field with software specific to the cutting machine application. The easy-to-use system combines advanced cutting performance with an intuitive graphical interface, and supports plasma, oxyfuel, and waterjet applications.

EDGE® Connect, Hypertherm’s newest Computer Numeric Control (CNC) plat- form, delivers unmatched reliability, powerful embedded capabilities, and a high level of customizability. Based on our proprietary, industry-leading Pho- enix® CNC platform, the system offers new, advanced software features – inc- luding ProNest® CNC automatic nesting delivering SureCutTM technology – along with enhanced hardware. For easy set up, changes, and upgrades, EDGE Connect CNCs can be configu- red in the field with software specific to the cutting machine application. The easy-to-use system combines advanced cutting performance with an intuitive graphical interface, and supports plasma, oxyfuel, and waterjet applications.

ProNest® LT (formerly known as TurboNest®) is a powerful CAD/CAM part nesting software designed for light industrial, mechanized cutting in production environments. It provides a single software solution for all your conventional plasma and oxyfuel cutting machines.

KRRASS 5-Axis beveling head is designed for 3D and angle cutting. Up to 45° all the angles are calculated automaticly and created so the operator can input the desired angles as needed. Also the straight vertical cuts can be done, reduced maintenance due to height detection sensor.

KRRASS CNC Controlled plasma cutting machines also provide oxygen cutting capability. With our oxygen head equipped machines up to 200 mm cut can be done and this limit can be increased with special design options.

The KRRASS Plasma series uses Hypertherm’s patented technologies for quality, more power, more precision and more consistent cutting.

During plasma cutting machine cutting operations filter is needed for extraction of smoke, dust and emissions. Creates a more better working environment for everybody, specially for plasma operators. Shipped in one piece by means of its specially defined dimensions, this way all accessories and pre-set and ready to startup. Particles carried by the dirty air entering through the side walls of filter cabin are held by means of a crashing plate. In this section, speed of the air is decreased and desired filtering rates are obtained. In addition, sparks that may touch the filter and big and corrosive particles are directed to the collecting bucket underneath the bunker. Thus, life of the filters is increased. Other dusts and smokes that constitute the polluted air are held by BIA-approved filter materials tested according to DIN EN 60335-2-69 appendix AAand selected according to the application. Dusts held are automatically cleaned thanks to jet pulse cleaning system. Cleaned air is absorbed from the cabin by means of a fan and released to the environment desired.

For more information, please refer to the following articles:

Reviewed by 7 users

The plasma cutter is a reliable and versatile machine that will exceed my expectations

The excellent customer service experience has added immense value to this purchase of this plasma cutter machine and the technical support team has been accommodating whenever I had questions or needed assistance with operating the plasma cutter.

Oxy Plasma Carbon Steel Cutting Machine

After a long time check and thinking ,finally , i booked one Oxy Plasma Steel Cutting Machine from KRRASS .

With the help from them on line by WA , I managed to install this machine . And works really in good condition .

As the old saying goes you get what you pay for , i am very happy about this machine .

A1500-4000 Oxy Plasma cutting machine

Very powerful machine ,with this machine , i finally achieve the project on time !!!

Oxy Plasma and Flame Carbon Steel Cutting Machine

A1500/4000 é realmente boa em qualidade e bem projetada, economiza tempo e é muito confiável. Com essa máquina, posso fazer mais negócios e contratar mais pessoas

The machine has been able to handle a variety of materials with precision and accuracy, which has greatly improved our production process. anyway, we appreciate it

I bought a good cutting machine, and it’s good