Plasma Cutter Machine

Discover how KRRASS plasma cutter machine technology can help you optimize your production. KRRASS is committed to providing customers worldwide with more productive sheet metal machines, new customized solutions, and easy-to-use option suites designed to meet the customer’s actual needs.

We are ardently committed to providing our esteemed clientele with pioneering solutions that boost productivity, enhance operational efficiency, and cater to their specific demands. Discover how our Plasma Cutter Machine technology can transform your cutting operations, optimize your workflows, and elevate your success to new pinnacles.

Inquire Now

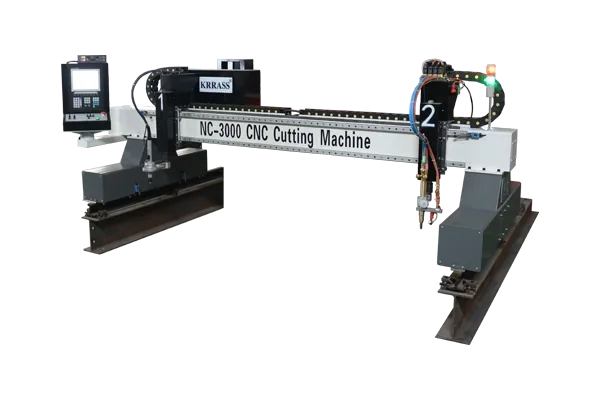

Plasma Cutting Machine

KRRASS Plasma Cutting Machine have been manufactured since 1995 and have been installed and working in a wide variety of sheet metal cutting operations for many industries. Years of experience has helped us develop durable, low distortion and precise Cutting.

Plasma cutting uses an accelerated jet of hot plasma to cut conductive materials. They use a conductive gas with a temperature of up to 30,000°C. Plasma cutting operates by creating an electrical channel of superheated, electrically ionized gas. This is called the plasma.

Plasma machines perform cutting by using a horizontally moving cutter plasma head on the fixed sheet placed on the table. They follow the sheet at a certain height by providing arc voltage control during cutting.

Plasma Cutting Machine List

P Plasma Cutter Machine

Table Type Plasma Cutting Machine

KRRASS P (Compact) Series plasma cutter machine has a modular frame. Modular frames are welded, and stress relief is performed after welding to ensure quality and accuracy. High-quality and precise plasma cutting is possible with double-sided synchronized gap-free planetary reducers that offer high precision. High positioning speed, acceleration, and automatic torch height control ensure the best cutting quality for your manufacturing needs.

P-C Plasma Cutter Machine

Oxy Plasma and Flame Carbon Steel Cutting Machine

KRRASS P-C Series plasma cutter machine has a high endurance frame structure. It is specifically designed for industries that necessitate heavy manufacturing. Cutting tables and movement axes are independent. This allows wielding of heavy materials. With its precise sliding equipment in X, Y and Z axes, it can operate in high positioning tolerance, and high acceleration values as in the P-C series.

Customer Case

FAQ

What is Plasma Cutting Machine?

Plasma cutter is an effective way to cut thin and thick materials. Plasma cutting can be used in hobby shops as well as wide-scale mass production. Plasma cutting is often used for a variety of industries. These industries include, automotive sector, construction sector as well as other types of manufacturing. Plasma cutting machines cut through conductive materials by using hot plasma. Typically, steel, stainless steel, aluminum and copper materials are used with plasma cutting. Other conductive metals can be cut also.

How Do Plasma Cutting Machines Work?

Plasma cutting uses an accelerated jet of hot plasma to cut conductive materials. They use a conductive gas with a temperature of up to 30,000°C. Plasma cutting operates by creating an electrical channel of superheated, electrically ionized gas. This is called the plasma. Plasma machines perform cutting by using a horizontally moving cutter plasma head on the fixed sheet placed on the table. They follow the sheet at a certain height by providing arc voltage control during cutting.

What Are the Advantages of Plasma Cutting Machines?

One of the main advantages of a plasma cutting machine is the variety of its applications. They can be used to cut metal in various thicknesses. Their applications vary from retail product design to industrial equipment. Secondly, having a plasma cutting machine will increase your production capabilities. Moreover, it will render your business independent. You won’t need to outsource your punching needs. This will save you money, time, energy and manpower. Thirdly, a sturdy and durable plasma cutting machine will increase your production. These machines are designed for consecutive uses. You can use your machine many times, without interruption to your production line. KRRASS Plasma Cutting Machines are durable. They will be with you for long and productive years. You will save time, energy and manpower due to our cutting-edge technology. Our R&D team continuously works to ensure that your machine is the best the market has to offer. Moreover, you will benefit from Durma after-sales services, we will be with you every step of the way.

What is KRRASS Plasma Cutting Machine Technology?

KRRASS plasma cutting benches offer different cutting options with plasma power supply options according to the needs of their customers. Helical rack gear, pinion and reducer are used, providing precise positioning and silent operation. The cutting table, with its horizontally and vertically separated suction sections, provides suction control at the highest capacity and removes dust and particles in the environment. The motor driver group is one of the leaders of the market, and it minimizes the need for service. Durma Plasma Cutting Machines have their own user panel. In this way, it understands the customer’s needs in the best way and provides a fast and efficient use.

Why Should You Choose KRRASS?

Business, like life, is a journey. With KRRASS machines, you will overcome all obstacles and surmount all challenges that business presents. We will be with you every step of the way. We know that your growth is our growth, and that your success is our success. As Durma, we manufacture machines that are durable, flexible and innovative. We aim for excellence in all our machines. We build trust with our customers and produce flawless tools. Our cutting-edge technology will get you clear-cut results, fast, with perfection. Krrass, means ‘Keep going’. With Krrass you will progress and produce continuously.

Reviewed by 40 users

Máquina de corte por plasma de buena calidad, funciona bien

Nice Plasma Cutting Machine,it works well.

ilike cnc press brake bending machine with DA58T

Superou minhas expectativas quando adquiri esta máquina de corte a plasma, krrass forneceu assistência útil sempre que necessário Hypertherm 125A

La máquina de corte por plasma es buena LGK 200A. El soporte técnico es helpfully.