When you have an plan to buy a fiber laser cutting machine for metal, there are some aspects you should take into account.What is a fiber laser cutting machine? what is it used for? how does it work? how to buy fiber laser cutters?

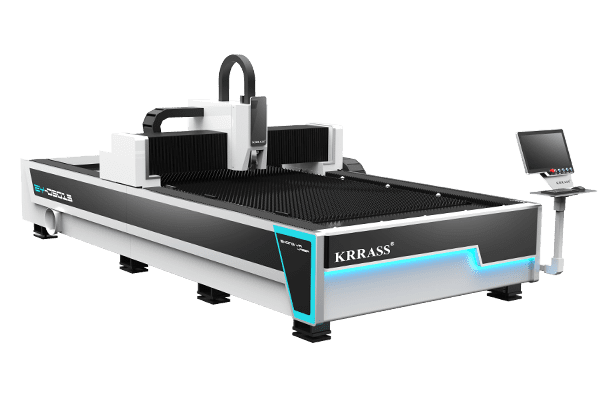

What is a fiber laser cutting machine

A fiber laser cutting machine for metal is a laser machine that emits light from a laser and focuses it into a high power density laser beam via an optical path system. The laser beam hits the surface of the workpiece, causing the workpiece to reach its melting point or boiling point, while the high-pressure gas coaxial with the beam blows the molten or vaporized metal away.

With the movement of the relative position of the beam and the workpiece, the material is finally cut to achieve the purpose of cutting. The laser cutting process replaces the traditional mechanical knives with invisible beams. It has high precision, fast cutting speed, is not limited to cutting pattern restrictions, and saves material by automatic typesetting, has a smooth incision, and has low processing costs.

It will gradually improve or replace traditional metal cutting process equipment. The mechanical part of the laser cutter head has no contact with the workpiece. It will not scratch the workpiece surface during work. The laser cutting speed is fast and the incision is smooth and flat. Generally no subsequent processing is required. The heat affected zone is small, the plate deformation is small, and the slit is narrow ( 0.1mm~0.3mm); No mechanical stress, no cutting burrs on the notch; High precision machining, good repeatability, no damage to the surface of the material; NC programming, can process any plan, can cut the whole board with a large format, without open mold, economical and time-saving.

What metals can the fiber laser cutting machine cut

Fiber laser cutting machines can cut all kinds of metal materials such as:

Iron、Alloy、Brass、Copper、Titanium、Aluminum、Carbon steel、Structural steel、Stainless steel

What is applied in

Fiber laser cutting machine applications are very extensive, include many industries, and it is one of the necessary equipment for many businesses.

- Advertising industry

- Sheet metal processing industry

- Chassis cabinet production

- Spring sheet production

- Subway parts

- Elevator manufacturing

- Kitchen kitchenware manufacturing

Fiber laser cutting machine for metal is widely applied in sheet metal processing, advertising sign making, high and low voltage electrical cabinet making, mechanical parts, kitchen utensils, automobiles, machinery, metal crafts, saw blades, electrical parts, eyewear industry, spring sheet, circuit board, electric kettle, medical micro Electronics, hardware, knife measuring tools and other industries.

What’s the working principle

Laser is a kind of light. Like the other kind of light, It is also produced by the transition of atoms (molecular or ionic, etc.). However, unlike ordinary light, laser light(Figure 5-1) is dependent on spontaneous radiation only for the first very short time. Since the process is completely determined by the excitation light, the laser has a very pure color, almost no divergent directionality, and high luminous intensity and high coherence.

Fiber laser cutting machine for metal is achieved by applying high power density energy generated by laser focusing. Under the control of a computer, the laser is discharged by pulses to output a controlled repetition of a high-frequency pulsed laser to form a beam of a certain frequency and a certain pulse width. The pulsed laser beam is conducted and reflected by the optical path and focused by the focusing lens group. On the surface of the processed object, a subtle, high-energy density light spot is formed.

The focal spot is located near the surface to be processed, and the processed material is melted or gasified at a high temperature in an instant. Each high-energy laser pulse instantly sputters a small hole in the surface of the object. Under the control of the computer, the laser processing head and the material to be processed are successively moved and plotted according to a pre-drawn pattern, so that the object is processed into the desired shape.

How to define the cutting quality

Cutting accuracy is the first factor in determining the quality of a CNC laser cutting machine.The four factors that affect the cutting accuracy of CNC laser cutting machine.

- The laser cohesion size of the laser generator. If after cohesion, the laser beam is very small, the cutting precision will be very high. After cutting, the gap will be very small too. It explains that the cutting quality and cutting precision are very good.If the beam from the laser generator is big, then cutting gap is also big. In this condition, the thicker the workpiece, the bigger the gap.

- The precision of the frame. Before working, we need check the each part of the frame. The vertical and horizontal of the frame should be very good. If there’s 0.1mm deviation of each part, with the machine working, it will be bigger and bigger.

- The shape of the laser beam. If the beam from the laser generator is taper, then cutting gap is also taper. In this condition, the thicker the workpiece, the bigger the gap.

- Different material will also cause different cutting quality. For example, in the same condition, there’s a big difference for cutting stainless steel and aluminum.

For cutting stainless steel the precision and cutting edge will be better than aluminum. The general speaking, the cutting quality of fiber laser cutting machine can be defined by those 5 standards.

- The quality of the cutting edge.

- The size of the slag of the cutting edge.

- The trimming perpendicularity and inclination.

- The cutting edge fillet size.

- Flatness.

Safety operation of a fiber laser cutting machine

Based on our experience, 13 details of the safe operation of the fiber laser cutting machine are summarized.

- Observe the safety rules of the cutting machine. Start the laser strictly according to the laser start up procedure.

- The operator must be trained to be familiar with the structure and performance of the equipment and master operating system knowledge.

- Put on the glasses if operate near the fiber laser beam.

Before finding out if the material is suitable for fiber laser, do not process it in case that it may cause steam and smoke.

When start operating, the operator can not leave or hand over to others. If need to leave, the operator should turn off the machine.

Put the fire extinguisher nearby. Turn off the machine if not operate. Do not put paper, leather or other flammable material near the laser beam.

If find any abnormal situation when operating, stop the machine immediately and troubleshoot or inform engineers.

Keep the laser, the frame and the surrounding area are clean, orderly and free of oil. Put the Workpiece, metal sheet and the scarp stacked as required.

When using gas, crush the welding wires should be avoided to avoid leakage accidents.The use of gas cylinders and transport should comply with the cylinder monitoring procedures. Do not expose the cylinder to sunlight or near heat sources. When opening the bottle valve, the operator must stand on the side of the bottle mouth.

Observe high pressure safety regulations when servicing. Every 40 hours of operation or weekly maintenance, every 1000 hours of operation, or every six months of maintenance, should be performed in accordance with regulations and procedures.

After turning on the machine, manually start the machine at low speed in X and Y direction to check if there is any abnormality.

After a new part program is entered, it should be tested and its operation checked.

When working, pay attention to observe the operation of the machine frame to avoid the machine getting out of the effective range or two machines collisions causing accidents.

Daily maintenance of a fiber laser cutting machine

The frame

- Before starting the machine every day, carefully check the working conditions of the laser working gas and cutting gas. If the gas pressure is not enough, it should be replaced promptly.

- Check if the X-axis zero point, Y-axis zero point, Z-axis zero point, laser preparation status, etc. are damaged, (check indicator).

- Check if there is any looseness of the zero point, limit switch of the X-axis, Y-axis, and Z-axis and the installation screws of the impact block, and whether the limit switch of each axis is sensitive.

- Check whether the circulating water level in the chiller is sufficient. If it is insufficient, it must be added in time.

- Check whether there is any leakage in the circulating water circuit of the external light path. Leakage must be handled in time, otherwise the life of the optical lens is affected.

- After each day of cutting, check the lens of the focusing lens for damage.

- Check whether the bellows of the outer light path is burned or damaged.

After the completion of the daily work, clean up the cutting waste in time, clean the work site, and keep the work site tidy and clean. At the same time, do a good job of cleaning the equipment to ensure that all parts of the equipment are clean and free of dirt.

After the daily work is completed, the drain valve of the air reservoir at the bottom of the air compressor is opened to drain, and the drain valve is closed after the waste water is discharged.

After the daily work is completed, press the shutdown step to shut down, then turn off the total power of the entire machine.

The laser generator

The laser generator should be maintained before starting up daily. K. Check the cooling water pressure is maintained between 3.5-5 Pa.L. Check the temperature of the cooling water, preferably the temperature of the water required for the selected laser generator.M. Check the height of the oil level in the laser generator vacuum pump. If not, add it.N. Check whether there is any leakage in the oil, water, and gas lines of the laser generator, and whether the vacuum pump or the pneumatic components in the resonator are leaking.

Learn more about our products, please visit and subscribe to our Youtube channel