Press brakes are indispensable machine tools in modern manufacturing. They play a vital role in bending and shaping sheet metal across diverse industries, including automotive, aerospace, construction, and fabrication . These machines achieve specific angles and radii by pressing the metal between a punch and a die.

The effectiveness and precision of this process significantly depend on the functionality of the press brake's axes. These axes control the intricate movements and adjustments necessary for both simple and complex designs. A thorough understanding of these axes, whether in a basic 2-axis machine or an advanced multi-axis CNC press brake, is paramount for achieving consistent, high-quality results. This understanding enhances accuracy and productivity and ultimately reduces material waste.

The first emphasis on precision, efficiency, accuracy, productivity, and waste reduction underscores the primary motivation for a deep understanding of press brake axes: the pursuit of operational improvement and cost-effectiveness within manufacturing environments. Manufacturers continually seek ways to perfect their production processes. Given that press brakes are fundamental tools in numerous sectors, a comprehensive grasp of how to maximize their capabilities through axis control directly addresses these crucial performance indicators.

Furthermore, a clear understanding of the axes and their proper manipulation directly translates to more precise bends. This precision, in turn, acts as a preventative measure against errors that can lead to scrapped parts, wasted material, and the necessity for time-consuming and costly rework. Consequently, companies that prioritize the acquisition and application of knowledge about press brake axis technology are well-positioned to gain a competitive edge. This advantage manifests through the production of higher quality products, the realization of lower production costs due to minimized waste and rework, and the ability to achieve faster turnaround times, all of which are critical in today's demanding manufacturing landscape.

Table of Contents

Deconstructing the Functionality of Individual Press Brake Axes (Y, X, R, Z, V)

The axes in press brakes define the directional movements that govern the positioning and operation of the machine's components. These controlled movements are essential for achieving correct and consistent bending, particularly when working with complex shapes and tight tolerances . Each axis serves a distinct purpose in the bending process.

The Y-axis, often forming two independently controlled cylinders labeled Y1 and Y2, dictates the vertical movement of the ram. The ram handles applying the necessary bending force to the sheet metal.

The X-axis manages the horizontal positioning of the back gauge. This precise control ensures the sheet metal is placed accurately relative to the punch and die, a critical factor in achieving the desired bend location.

For applications requiring varying flange heights, the R-axis comes into play, adjusting the vertical movement of the back gauge fingers.

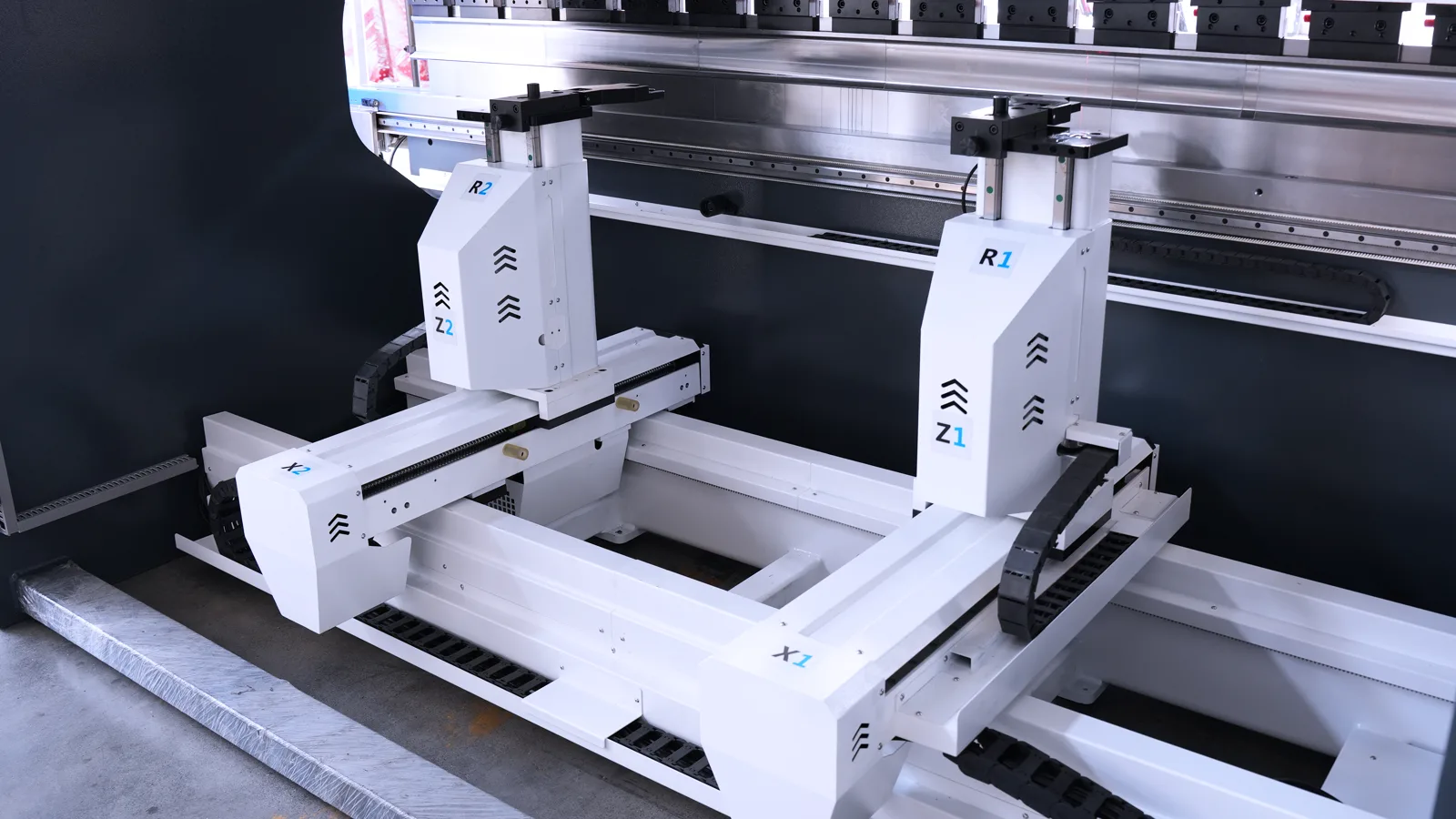

The Z-axes, typically appointed as Z1 and Z2, enable the lateral movement of the back gauge fingers. This independent control is particularly useful for executing intricate bends that require different positioning along the width of the workpiece.

Finally, the V-axis addresses the issue of machine bed deflection. By compensating for this natural deformation that can occur under bending loads, especially with longer sheets or high-tension materials, the V-axis ensures uniform bending angles across the entire length of the workpiece.

The presence of these multiple axes signifies an industry-wide trend towards increasingly complex and precise control over the sheet metal bending process. The differentiation between Y1 and Y2 axes on many machines further underscores the importance of independent control for specialized applications, such as creating tapered bends or compensating for variations in material thickness across the workpiece.

The precise positioning eased by the X and Z axes directly influences the accuracy of the bend's location on the metal sheet. If the back gauge is not positioned correctly along either the horizontal (X) or lateral (Z) planes, the resulting bend will occur at an unintended location, leading to dimensional inaccuracies in the final part.

Similarly, the V-axis plays a crucial role in the uniformity of the bending angle. Without its compensation for machine bed deflection, longer workpieces or those made from materials showing high tensile strength might display inconsistencies in the bend angle along their length, compromising the quality and dimensional accuracy of the finished product.

The availability of these diverse axes empowers manufacturers to produce a wider array of parts with enhanced accuracy and consistency. This capability can open doors to new market opportunities that demand intricate designs and tight tolerances. Moreover, the increased precision afforded by multi-axis control can reduce or even cut the need for secondary operations, such as manual adjustments or added forming processes, thereby streamlining production and potentially lowering overall manufacturing costs.

Understanding Different Press Brake Axis Configurations and Their Applications

The number of axes incorporated into a press brake directly correlates with its ability to manage a variety of bending operations and meet diverse manufacturing needs . These axes are categorized based on the specific movements they control, such as the ram's vertical movement (Y-axis) or the back gauge's adjustments (X, R, and Z axes). Understanding these configurations is essential for deciding a press brake's overall versatility and the level of precision it can achieve.

Common axis configurations include the 2-axis machine, which features control over the Y-axis (ram movement) and the X-axis (back gauge horizontal positioning). This configuration is typically used for simple bending tasks and smaller workpieces.

The 3+1 axis configuration builds upon this by adding independent control for the ram cylinders (Y1 and Y2) and incorporating a V-axis for crowning compensation. This allows for more consistent bending angles, especially on longer materials.

The 4+1 axis press brake further enhances capabilities by including an R-axis, which provides vertical adjustment of the back gauge fingers. This added axis is beneficial for producing parts with varying flange lengths.

For more complex or asymmetrical parts, a 6+1 axis machine is often employed. This configuration includes Y1, Y2, X, R, Z1, Z2, and V axes, enabling lateral movement of the back gauge fingers for intricate bends.

Finally, the 8+1 axis configuration is the most advanced level of control, featuring Y1, Y2, X1, X2, R1, R2, Z1, Z2, and V axes. The added X and R axes provide independent control over each back gauge finger, offering unparalleled precision for highly intricate tasks and large-scale production.

The progression from basic 2-axis machines to sophisticated 8+1 axis configurations clearly illustrates an increasing demand within the manufacturing sector for greater flexibility and precision in bending operations. The consistent inclusion of the V-axis (often denoted by the "+1") in higher-end configurations highlights the critical importance of crowning compensation in achieving accurate and uniform bends, particularly when dealing with longer or thicker materials that are more susceptible to machine bed deflection under load.

The number of axes directly dictates the complexity of the bends a press brake can perform. For instance, a simple 2-axis machine is limited to basic, straight bends due to its lack of control over back gauge height or lateral positioning. However, the addition of the R-axis in a 4+1 configuration unlocks the ability to produce parts with different flange lengths in a single operation, a task impossible for a 2-axis machine. Similarly, the Z-axes in a 6+1 or 8+1 configuration enable the creation of complex, non-linear bends and asymmetrical parts that would require multiple setups or specialized tooling on less advanced machines. This progression in axis control allows for greater design freedom and the production of more intricate components.

Consequently, businesses must carefully evaluate their specific production requirements to make an informed investment in a press brake with the proper number of axes. Over-investing in a machine with capabilities that are rarely or never used can lead to unnecessary capital expenditure and potentially higher maintenance costs. Conversely, under-investing in a machine with insufficient axes can limit a company's ability to fulfill certain types of orders or need costly outsourcing of complex bending tasks. Therefore, a thorough understanding of the relationship between axis configuration and bending capability is crucial for making a strategic purchasing decision that aligns with both current and future production needs.

Table: Common Press Brake Axis Configurations and Their Applications

| Number of Axes | Axis Configuration | Description of Capabilities | Typical Applications |

|---|---|---|---|

| 2 | Y, X | Basic bending with control over ram movement and back gauge horizontal positioning. | Simple right-angle bends on uniform, smaller sheets. |

| 3+1 | Y1, Y2, X, V | Independent ram control and crowning compensation for consistent angles, especially on longer workpieces. | Parts needing uniform angles across their length. |

| 4+1 | Y1, Y2, X, R, V | Adds vertical back gauge adjustment for varying flange lengths and material thicknesses. | Parts with multiple bends and different flange heights. |

| 6+1 | Y1, Y2, X, R, Z1, Z2, V | Enables lateral back gauge movement for complex or asymmetrical parts with bends at varying positions. | Automotive, aerospace, custom fabrication of intricate multi-bend parts. |

| 8+1 | Y1, Y2, X1, X2, R1, R2, Z1, Z2, V | Advanced control with independent horizontal and vertical movement of back gauge fingers for highly intricate tasks. | Aerospace, high-precision applications requiring complex shapes and tight tolerances. |

Deciding the Ideal Number of Axes for Specific Bending Requirements

Deciding the ideal number of axes for a press brake is a critical decision that hinges on a thorough understanding of the specific bending requirements, the types of materials being processed, and the expected production volumes . A press brake requires a minimum of two axes, the Y-axis (controlling the ram's vertical movement for bending force) and the X-axis (managing the back gauge's horizontal positioning for sheet metal alignment), to perform basic bending tasks . This 2-axis configuration is often sufficient for simple applications such as creating right-angle bends on uniform, smaller sheets of material. However, it lacks the necessary flexibility to manage more complex parts due to its limited adjustments for material thickness, flange length, or lateral positioning of the workpiece.

The ideal number of axes extends beyond this minimum and is directly influenced by the complexity of the parts being manufactured, the variety of material types used, and the required production volumes . While a 2-axis machine might suffice for considerably basic operations, more advanced configurations become necessary to achieve the precision and intricate geometries demanded in many modern manufacturing scenarios.

To make an informed decision, several crucial factors must be considered . The complexity of the bending operations is paramount; simple, straight bends require fewer axes, while intricate designs with multiple bends, varying flange lengths, or asymmetrical features need machines with a greater number of controlled movements.

Material specifications, including the type, thickness, and length of the material, also play a significant role. Thicker materials may require the crowning compensation provided by the V-axis to ensure consistent bending angles across the workpiece, and longer sheets can receive help from the independent lateral control offered by Z1 and Z2 axes.

The required level of precision and accuracy directly affects the need for axes that offer independent control, such as the Y1 and Y2 axes for the ram. Back gauge requirements also need careful consideration; the desired flexibility in the back gauge system, enhanced by the R, Z1, and Z2 axes, decides the range of workpieces that can be effectively managed.

Furthermore, tooling considerations can influence axis requirements, as specialized tooling might need more axes for proper alignment and compatibility. The level of automation and software integration wanted also plays a crucial role, as CNC brakes with advanced axis controls allow for greater automation and better synchronization of movements, leading to increased efficiency and repeatability. Finally, even space and layout constraints within the workshop can indirectly influence the choice of machine and its axis configuration.

The emphasis on these "requirements" and "factors to consider" underscores the importance of adopting a needs-based approach when selecting a press brake. There is no universal solution; the best choice depends entirely on the specific circumstances and demands of the manufacturing operation.

Higher production volumes often need machines with more axes and advanced automation capabilities to maximize efficiency and throughput. For example, a company producing a large quantity of identical, simple brackets might find a well-designed 2-axis machine sufficient. However, a shop specializing in smaller batches of overly complex parts made from various materials will likely require a multi-axis machine with features like independent ram control, back gauge height and lateral adjustments, and crowning compensation.

Similarly, the type and thickness of the materials being processed can dictate the need for specific axes. Thicker materials are more prone to machine bed deflection, making the V-axis for crowning essential to achieve uniform bends. Longer sheets also benefit significantly from the independent lateral control of the back gauge fingers (Z1 and Z2 axes), which allows for precise positioning and prevents twisting or misalignment during the bending process.

A thorough and correct assessment of these factors can lead to significant cost savings and improved production efficiency. Investing in a machine with the precise capabilities needed avoids the pitfalls of both overspending on unnecessary features and underspending on a machine that cannot meet the required specifications. Conversely, a mismatch between the machine's capabilities and the actual production needs can result in bottlenecks, increased production costs due to scrap and rework, and ultimately, an inability to meet customer demands effectively.

The Impact of Axis Configuration on Press Brake Efficiency and Accuracy

The various axes incorporated into a press brake collectively decide its overall precision, functional versatility, and adaptability to a wide spectrum of bending operations . These axes govern critical movements such as the precise positioning of the sheet metal, the adjustment of the back gauge to ensure correct bend location, and the controlled motion of the ram to apply the necessary bending force. The coordinated action of these axes is fundamental to achieving correct bending angles and keeping efficient workflows throughout the manufacturing process.

For instance, in machines equipped with independent ram control (Y1 and Y2 axes), the bending force can be applied consistently and evenly across the workpiece, leading to more correct and repeatable bends. The X-axis, by precisely controlling the horizontal position of the back gauge, ensures that each bend is made at the intended location on the sheet metal . Furthermore, the inclusion of added axes like the R-axis (vertical back gauge adjustment) and the Z-axes (lateral back gauge movement) provides the flexibility needed to execute complex bends and achieve tight tolerances, particularly on parts with intricate geometries or multiple bend lines.

The focus on efficiency and accuracy underscores the fundamental advantages of using the proper axis configuration for a given bending task. Generally, a higher number of axes translates to a greater potential for both increased precision and improved efficiency in the bending process. The evolution of press brakes towards incorporating more axes is largely driven by the ever-increasing demand for manufactured parts with tighter tolerances and more complex designs. Each added axis introduces a further degree of control over the bending process, directly contributing to both the accuracy of the final product and the overall speed and efficiency of its production.

More precise control over the ram (Y1 and Y2 axes) and the back gauge (X, R, Z axes) directly results in more correct bending angles and overall part dimensions. This increased accuracy, in turn, significantly reduces the amount of scrap material produced and minimizes the need for costly and time-consuming rework. By producing parts correctly the first time, manufacturers can improve their overall efficiency and reduce their operational costs.

When a press brake can accurately position the material and apply the correct bending force at the precise location, the probability of producing a part that meets the required specifications on the first attempt is dramatically increased. This not only saves material and reduces waste but also minimizes the time and resources that would otherwise be spent on finding and correcting errors. Consequently, companies that use press brakes with optimized axis configurations are likely to experience higher production throughput, lower overall operating costs, and improved customer satisfaction due to the consistently high quality of their products.

The efficiency and accuracy of the bending process have a direct and significant impact on the overall productivity and profitability of a manufacturing operation. Therefore, investing in a press brake with the proper axis configuration is not merely a purchase of equipment; it is a strategic investment in enhancing these key areas of performance.

Exploring the Core Components of a Press Brake's Axis System

The axis system of a press brake is a complex assembly of interconnected components that work in concert to achieve precise and controlled bending operations . The ram, controlled by the Y1 and Y2 axes, is a primary part, responsible for the vertical movement of the press brake's upper beam. This movement applies the necessary pressure to the tooling (punch and die) to achieve the desired bending angles in the sheet metal.

The back gauge, guided by the X, R, Z1, and Z2 axes, plays a crucial role in precisely positioning the sheet metal before and during the bending process. It features horizontal adjustment (X-axis) to control the distance of the bend from the edge of the material, vertical adjustment (R-axis) to accommodate varying flange heights, and lateral adjustments (Z1 and Z2 axes) for intricate bends requiring different positioning along the workpiece width.

The entire operation of the axis system is orchestrated by the CNC control system. This sophisticated electronic system manages and synchronizes the movements of all the axes based on the operator's programmed instructions, ensuring consistent and repeatable bending results.

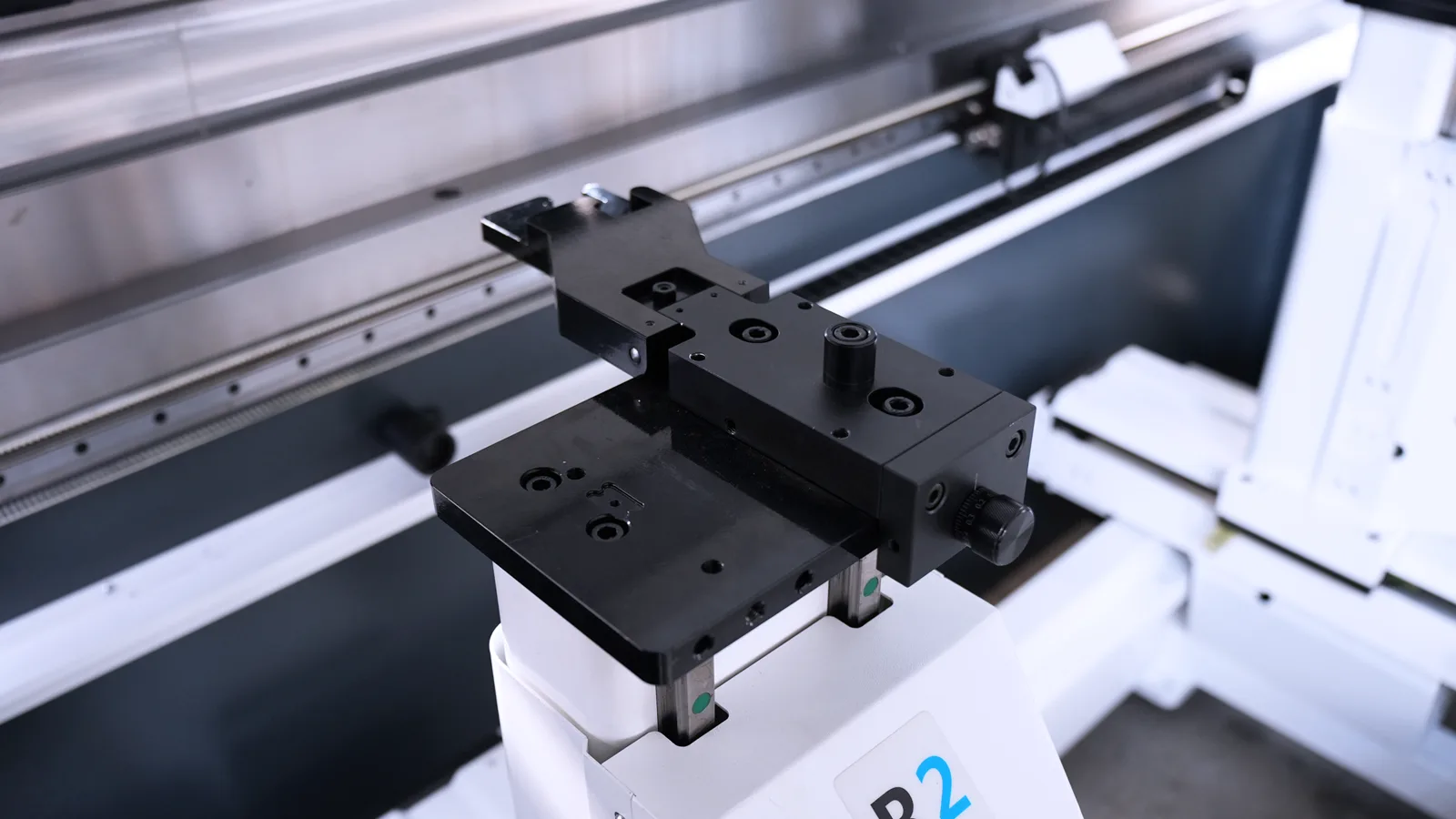

Back gauge fingers are essential for securely holding the metal sheet in the correct position against the back gauge during the bending operation, which is critical for keeping precision.

The tooling, consisting of the punch and die, defines the shape of the bend and ensures that the material conforms to the required angle. The compatibility of the tooling with the machine's axis capabilities directly affects the overall versatility of the press brake.

To ease smooth and correct movement of the axes, linear guides and ball screws are employed, minimizing friction and ensuring precise positioning, which is vital for reducing errors in the bending process.

The force needed for the ram's movement is typically provided by hydraulic cylinders, which ensure that the sheet metal is bent with the programmed force and to the correct angle.

Finally, sensors and feedback systems are integrated into the axis system to check the actual positions of the axes and the resulting bending angles in real-time. This feedback allows the CNC control system to make minute adjustments during the bending cycle, further improving accuracy and consistency.

The intricate nature of this axis system, encompassing mechanical, hydraulic, and electronic components, underscores the sophisticated engineering inherent in modern press brakes. The integration of sensors and feedback mechanisms highlights the importance of closed-loop control systems in achieving the elevated levels of accuracy demanded in contemporary manufacturing.

The precision of components like linear guides and ball screws directly affects the accuracy of the axis movements. If these mechanical elements are not manufactured to tight tolerances and kept properly, the machine will struggle to achieve the desired precision, regardless of the sophistication of the CNC control system.

Similarly, the CNC control system acts as the brain of the operation, dictating how the various axes are coordinated. Its ability to precisely control the timing and position of each axis movement directly influences the quality and accuracy of the final bend.

The reliability and performance of these core components have a direct impact on the overall uptime and productivity of the press brake. A failure in any of these elements can lead to machine downtime, production delays, and potentially significant repair costs. Therefore, a thorough understanding of these components and the importance of their regular maintenance is essential for ensuring consistent and efficient press brake operation. Initiative-taking maintenance, including regular inspection, lubrication, and calibration, can help to prevent premature failures and extend the lifespan of these critical components, ultimately protecting the investment in the machinery.

The Crucial Role of the Back Gauge in Sheet Metal Positioning

The back gauge is an indispensable part of a press brake, playing a vital role in accurately positioning and guiding the sheet metal during the bending process . Its primary function is to ensure the correct alignment of the workpiece with the tooling (punch and die), which is fundamental for achieving consistent bending angles and precise final dimensions.

The back gauge's position is controlled by several axes, including the X-axis, which determines the distance of the bend line from the edge of the sheet metal; the R-axis, which adjusts the vertical height of the back gauge fingers to accommodate variations in flange heights or material thicknesses; and the Z1 and Z2 axes, which allow for lateral positioning of the back gauge fingers, enabling the creation of bends at different points along the width of the workpiece.

Different back gauge configurations are available to suit varying levels of bending complexity. A BG-1 configuration typically features only the X-axis, making it suitable for basic bending tasks where the bend needs to be a specific distance from a single edge of the material . The BG-2 configuration expands on this by adding the R-axis, providing greater flexibility for more complex bends and different material thicknesses . For advanced, high-precision operations, a BG-4 configuration is often used, which incorporates all four axes: X, R, Z1, and Z2. This allows for highly precise and versatile positioning of the sheet metal, enabling the creation of intricate parts with multiple bends and varying flange geometries.

The evolution of back gauge configurations, from simple X-axis control to more sophisticated systems incorporating R and Z axes, reflects the increasing demand for precise and versatile material handling capabilities during the bending process. Early press brakes were equipped with considerably basic back gauges, often requiring manual adjustments. As the complexity of bent parts increased, so did the need for more advanced systems that could accurately position the material in multiple dimensions, often under CNC control.

The accuracy of the back gauge positioning directly decides the accuracy of the bend's location on the workpiece and, so, the final dimensions of the manufactured part. Even slight inaccuracies in back gauge placement can lead to parts that do not meet specifications, resulting in scrap or the need for rework.

The availability of R and Z axes on the back gauge significantly enhances the machine's ability to create more complex flange geometries and asymmetrical bends. For example, the R-axis allows for the creation of parts with different flange lengths in a single bending operation, while the Z-axes enable the production of parts with bends that are not parallel to each other or that occur at different lateral positions. These capabilities are essential for manufacturing a wide range of intricate components.

An efficient and correct back gauge system can significantly reduce setup times for bending operations. With precise CNC control over the back gauge axes, operators can quickly and easily program the required positions for each bend, minimizing the need for manual adjustments and trial-and-error. This automation of the back gauge positioning process also improves the repeatability of bending operations, ensuring that each part is produced to the same high standard of accuracy. The combination of reduced setup times and improved repeatability leads to increased overall productivity and a reduction in scrap rates, ultimately contributing to a more efficient and cost-effective manufacturing process.

A Comparative Look at Basic and Advanced Press Brake Axis Setups

Press brakes are available in a range of axis configurations, from basic to highly advanced, each designed to suit various levels of bending complexity and precision requirements . Understanding these different setups is crucial for selecting the right machine for specific manufacturing needs.

Basic configurations typically include 2-axis machines, which control the Y-axis (ram movement) and the X-axis (back gauge horizontal positioning). These machines are suitable for simple bending tasks where high precision is not critically required . A slight step up is the 3-axis configuration, which adds an R-axis to the Y and X axes, providing vertical adjustment of the back gauge. This offers slightly more versatility, particularly when dealing with varying sheet thicknesses or desired flange heights.

Intermediate configurations offer a greater degree of control and precision. The 4+1 axis machine (Y1, Y2, X, R, V) introduces independent control of the ram cylinders (Y1 and Y2) and a V-axis for crowning compensation. This setup ensures more consistent bending angles, especially on longer or thicker materials . The 6+1 axis configuration (Y1, Y2, X, R, Z1, Z2, V) further enhances capabilities by adding Z1 and Z2 axes, which allow for independent lateral movement of the back gauge fingers. This is essential for producing complex parts with bends at varying positions along their width.

Advanced configurations are the pinnacle of press brake technology. 8+1 axis machines and beyond feature even more axes, providing highly precise adjustments and enabling greater automation for intricate bending tasks. These advanced machines are commonly used in industries like aerospace and automotive, where complex shapes and tight tolerances are paramount.

The categorization of press brakes into basic, intermediate, and advanced configurations provides a helpful framework for understanding the trade-offs between the first cost of the machine, its operational complexity, and its overall bending capabilities. Generally, machines with fewer axes are more cost-effective and simpler to run but offer limited versatility. Conversely, machines with a higher number of axes are more expensive and may require more skilled operators but can manage a wider range of complex bending tasks with greater precision.

The addition of each axis to a press brake increases its ability to manage more complex bending tasks. For example, while a 2-axis machine is limited to relatively simple, straight bends, the addition of the R-axis in a 3-axis machine allows for adjustments in flange height, making it more versatile. The further addition of Z-axes in a 6+1 axis machine unlocks the capability to produce intricate, non-linear bends and asymmetrical parts that would be impossible to create on simpler machines without multiple setups or specialized tooling.

However, this increased capability comes with a corresponding increase in the first purchase price and potentially higher maintenance costs due to the greater number of moving parts and more complex control systems. Businesses must carefully consider the types of projects they typically undertake and their expected future needs when deciding on the proper axis configuration.

While a basic machine might be sufficient for their current production, it could significantly limit their ability to take on more complex or higher-value projects in the future. Therefore, it is often prudent to consider potential future growth and the possibility of needing to produce more intricate parts when making the purchasing decision. Investing in a machine with slightly more capability than currently needed can provide a competitive advantage and prevent the need for another significant capital investment soon.

Factors to Consider When Investing in a Multi-Axis Press Brake

When making the decision to buy a multi-axis press brake, it is crucial to conduct a thorough assessment of current and future operational needs and long-term business goals . Several key factors should be carefully evaluated to ensure that the chosen machine meets the specific requirements of the manufacturing operation.

The complexity of the bending operations that will be performed is a primary consideration. If most of the work involves simple, straight bends, a machine with fewer axes might suffice. However, if the production includes intricate designs with multiple bends, varying flange lengths, or asymmetrical features, a machine with R, Z1, and Z2 axes will be necessary.

Material specifications also play a significant role. The type, thickness, and length of the materials being processed can influence the required axis configuration. For instance, thicker materials might need a V-axis for crowning compensation to prevent bed deflection and ensure consistent bending angles, while longer sheets might receive help from the added control offered by Z1 and Z2 axes.

The level of software integration and automation desired is another crucial factor. Modern multi-axis presses brakes often come with sophisticated CNC control systems and software that can streamline programming and operation. If the goal is to increase efficiency and reduce manual intervention, a machine with advanced software capabilities and the ability to integrate with other automation systems should be considered.

Future scalability is also a crucial aspect. It is wise to consider potential future growth and changes in production requirements. Investing in a machine with slightly more capability than currently needed can provide flexibility and prevent the need for an early replacement if production needs evolve.

Finally, compatibility with existing tooling should be assessed. If the company already has a significant investment in press brake tooling, it is important to ensure that the new multi-axis machine is compatible with this tooling to avoid added costs and complexities.

The range of these factors highlights that buying a press brake is not a simple decision based solely on the number of axes. It requires a comprehensive evaluation of various operational and strategic aspects of the business.

The complexity of the bending operations directly dictates the required number of axes. For example, producing simple brackets will have different axis requirements compared to manufacturing intricate components for the aerospace industry. Similarly, the need for automation will influence the type of CNC control system and the level of axis control needed for efficient operation.

The type of materials being processed can also significantly affect the decision. Thicker or higher-strength materials may require more force and the crowning compensation offered by the V-axis. The need for automation might need a CNC press brake with advanced axis controls and seamless software integration to streamline the production process and reduce manual labor.

Considering future scalability ensures that the investment in a new press brake will continue to meet the company's needs as it grows and evolves. Choosing a machine with slightly more capability than currently needed can provide a buffer for future expansion or changes in product design.

A thorough evaluation of these factors can lead to a well-informed investment that aligns with the company's current and future needs, ultimately maximizing productivity and profitability. Conversely, overlooking key factors can result in buying a machine that is either insufficient for the required tasks or unnecessarily expensive for the actual workload.

Does the Number of Axes Affect the Cost of a Press Brake?

Yes, there is a direct correlation between the number of axes on a press brake and its cost . As the number of controlled axes increases, the complexity of the machine, its control systems, and its overall capabilities also increase, which is reflected in a higher purchase price.

A 2-axis press brake (X and Y) is the most basic configuration and is generally the most cost-effective choice, suitable for fundamental bending operations.

Moving up to a 3-axis machine (X, Y, R) introduces vertical back gauge adjustment, adding to the machine's flexibility and resulting in a slightly higher cost.

4-axis machines (X, Y, R, and typically Z1 or Z2) that offer lateral back gauge positioning incur a further increase in cost due to their enhanced capabilities.

6-axis and above press brakes, with their advanced features and sophisticated control systems, represent a substantial investment. These machines are designed for high-precision industries and complex bending tasks.

Additionally, the inclusion of features like the V-axis for crowning compensation, while crucial for certain applications, also adds to the overall price of the machine.

The clear trade-off between the capability of a press brake, as shown by the number of axes, and its cost needs a careful balancing act for businesses when making a purchasing decision. It is essential to find the best balance between the machine's features and the specific bending requirements of the manufacturing operation, while also considering budgetary constraints.

Analyzing the complexity of the bending tasks that will be performed is crucial for achieving this balance. For operations that primarily involve simple, straight bends on smaller, uniform materials, a 2-axis press brake can be a cost-effective solution.

However, for more advanced applications that require intricate shapes, multiple bends at different angles, or varying flange lengths, machines with four or more axes (including R and Z1/Z2) become necessary. While these more capable machines come with a higher first cost, they can significantly improve efficiency by reducing setup times, minimizing errors, and enabling the production of more complex parts in a single operation, potentially leading to long-term cost savings.

It is also important to consider potential future needs. While a basic machine might meet current production demands, investing in a 6+ axis CNC press brake could prove more economical overall if the business expects taking on more complex projects or expanding its product line.

These more advanced machines often offer greater compatibility with advanced tooling and automation systems, providing a foundation for future growth and increased productivity. Therefore, a strategic approach that considers both immediate needs and long-term goals is essential when balancing the cost and capability of press brake axis configurations.

How to Choose the Right Press Brake?

Selecting the proper press brake for your manufacturing needs requires a comprehensive understanding of your operational demands and long-term objectives . This involves a careful evaluation of several key factors, with a particular focus on axis requirements, the types of bending operations to be performed, and the specifications of the materials being processed.

Primarily, it is essential to clearly define the axis requirements based on the complexity of the parts you intend to produce. As discussed earlier, simple bends require fewer axes, while intricate designs need machines with a greater number of controlled movements.

Next, thoroughly consider the bending operations that will be performed most often. Will you primarily be doing single bends, or will you need to produce parts with multiple bends, varying angles, or complex geometries? The answers to these questions will directly influence the required axis configuration and the overall capabilities of the press brake.

The material specifications are also critical. The type of material you will be working with (e.g., steel, aluminum, stainless steel), its thickness, and its length can all affect the type of press brake needed. For instance, thicker or longer sheets may require a machine with V-axis crowning to compensate for deflection and ensure correct bends.

Furthermore, consider your production volume. If you have high production demands, investing in a multi-axis CNC press brake with automation capabilities can significantly improve efficiency and throughput.

Space constraints within your workshop should also be considered, as different press brake models and configurations can have varying footprints.

Finally, evaluate the software compatibility of the press brake's control system with your existing design and manufacturing software. Seamless integration can streamline the programming and operation of the machine, making it easier to manage complex bending tasks.

KRRASS, as an example, offers a wide range of press brakes, from 2 to 11 axes, designed to provide durability, efficiency, and precision across various metalworking applications .

The emphasis on understanding operational needs and long-term goals highlights the importance of a strategic approach to press brake choice. It is not simply about buying a piece of machinery; it is about investing in a solution that directly addresses specific manufacturing requirements and supports the overall business aims.

The type of materials used will directly influence the required features of the press brake. For example, bending thicker materials often needs a higher tonnage ability and the inclusion of a V-axis for crowning. Similarly, the length of the material can dictate the required bed length and potentially the need for added back gauge support.

High production volumes often need a more automated and efficient machine, such as a multi-axis CNC press brake, to meet the demand and minimize cycle times. Making an informed decision about the right press brake can lead to significant improvements in productivity, the quality of the finished products, and overall cost-effectiveness. Conversely, a poorly informed choice can result in operational inefficiencies, limitations in production capabilities, and potential financial losses. Therefore, a thorough analysis of all these factors is crucial before making a final purchasing decision.

What Are Some Common Problems and Defects with Press Brake Axes?

Despite their robust design, press brake axes can experience various problems and defects that can affect their accuracy and performance . One common issue is the misalignment of the back gauge, which can occur due to normal wear and tear or improper calibration. This misalignment can lead to inconsistent bend locations and inaccurate part dimensions.

Inconsistent bending angles are another frequent problem, often stemming from uneven pressure application by the ram or incorrect settings of the Y1 and Y2 axes in machines with independent ram control.

Axis control failure can also occur, typically due to errors or malfunctions within the CNC system that manages the axis movements.

Over time, mechanical components such as the Z1 and Z2 axes and the hydraulic cylinders that power the ram can experience excessive wear, leading to reduced precision and potential failures.

Finally, hydraulic leaks within the system can affect the ram's movement and the overall bending efficiency of the machine . The inclusion of these common problems underscores the importance of regular maintenance and proper operation to ensure the longevity and accuracy of the press brake.

The misalignment of the back gauge directly affects the accuracy of the bend location, leading to parts that do not meet dimensional specifications. Similarly, inconsistent bending angles result in parts that do not have the intended shape or functionality. Axis control failures can bring the entire bending process to a halt, causing significant production delays.

Excessive wear on mechanical components can gradually degrade the machine's performance, leading to less precise bends and eventually requiring costly repairs or replacements. Hydraulic leaks can not only reduce the power and efficiency of the machine but also pose safety hazards in the workplace.

How to Maintain Press Brake Axes?

Proper maintenance is essential for ensuring the continued accuracy, efficiency, and longevity of press brake axes . Regular cleaning of the machine is important to prevent dust and debris from interfering with the smooth operation of the axes and other moving parts.

Lubrication of moving components, such as the Y1, Y2, and R axes, helps to reduce friction and wear, extending the lifespan of these parts.

Periodic calibration of the entire axis system, including both the back gauge and the ram, is crucial for keeping bending accuracy and ensuring that the machine runs within its specified tolerances.

Regular inspection of components like the back gauge fingers and hydraulic cylinders for signs of wear and tear is necessary, and worn parts should be replaced promptly to prevent further damage or inaccuracies.

For CNC-controlled machines, it is important to check the CNC system for any errors and to ensure that the software is kept up to date with the latest versions and patches.

Periodic testing of bending angles using calibrated measuring tools can help to detect any deviations from the programmed values, showing a potential issue with one or more of the axes.

Finally, regular checks of the hydraulic system for any signs of leaks or pressure issues are essential for keeping the ram's performance and overall machine safety.

An initiative-taking approach to maintenance, encompassing these key areas, can significantly improve the overall efficiency and reliability of the press brake. Regular cleaning prevents the buildup of contaminants that can impede the movement of the axes and cause premature wear. Proper lubrication minimizes friction between moving parts, reducing wear and tear and ensuring smooth operation. Calibration ensures that the programmed movements of the axes correspond accurately to the actual movements, keeping bending precision.

Regular inspections allow for the early detection of worn or damaged components, enabling prompt replacement before they cause more significant problems or lead to machine downtime. Monitoring the CNC system and keeping its software updated helps to prevent errors and ensures best performance of the axis controls. Periodic testing of bending angles provides a direct measure of the machine's accuracy and can highlight any issues that need to be addressed. Finally, regular checks of the hydraulic system are crucial for preventing leaks and ensuring that the ram runs with the correct force and speed.

Safety Considerations for Operating Multi-Axis Press Brakes

Operating multi-axis press brakes requires strict adherence to safety protocols to prevent accidents and ensure the well-being of personnel . Comprehensive operator training is paramount, ensuring that all individuals running the machine have a thorough understanding of its specific features, the CNC control system, and all associated safety procedures.

Regular inspections of critical components, such as the back gauge, stop fingers, and ram, should be conducted to check for any signs of wear, damage, or misalignment.

Operators must always use proper protective equipment, including gloves, safety goggles, and steel-toe boots, to minimize the risk of injury.

Maintaining clear workspaces around the press brake is essential to prevent trips and falls and to ensure unobstructed access to the machine's controls and emergency stops.

Proper workpiece setup is crucial; operators must ensure that the sheet metal is correctly positioned using the back gauge and that all stop fingers are securely in place before starting the bending cycle.

It is also vital to always respect the load limits of the machine and never exceed its rated ability for material thickness or flange length, as this can lead to machine damage or hazardous situations.

The emphasis on these safety protocols underscores the potential hazards associated with operating powerful machinery like multi-axis press brakes. Thorough operator training equips individuals with the knowledge and skills necessary to run the machine safely and effectively. Regular inspections help to find and address potential safety hazards before they can lead to accidents.

The use of proper protective equipment provides a crucial barrier against potential injuries. Maintaining clear workspaces minimizes the risk of slips, trips, and falls in the vicinity of the machine. Proper workpiece setup ensures that the material is managed and bent in a controlled manner, reducing the risk of unexpected movements or material ejection. Adhering to the machine's load limits prevents overloading, which can cause mechanical failures and potentially dangerous situations.

Environmental Considerations and Energy Efficiency

Modern multi-axis press brakes are increasingly designed with environmental considerations and energy efficiency in mind, contributing to more sustainable manufacturing practices . The incorporation of energy-efficient drives, such as modern servo-hydraulic systems, perfects energy consumption compared to traditional hydraulic systems, reducing the overall power usage of the machine.

Advanced axis configurations and precise control capabilities contribute to minimizing material waste by improving bending accuracy and reducing the occurrence of errors that lead to scrap parts.

Many modern press brakes are also designed to be compatible with recyclable materials, further supporting sustainability efforts within the manufacturing industry.

Compared to older models, newer multi-axis presses brakes often feature quieter operation, leading to reduced noise pollution in the workplace.

Finally, regular maintenance and upgrades to the machine's control system can ensure best energy usage and extend the lifespan of the equipment, contributing to long-term sustainability.

The focus on these environmental aspects reflects the growing global awareness of the importance of sustainable manufacturing practices. The use of energy-efficient drives directly translates to lower operating costs and a reduced carbon footprint. Minimizing material waste not only saves resources but also reduces the environmental impact associated with raw material extraction and processing.

Compatibility with recyclable materials promotes a circular economy and reduces the amount of waste sent to landfills. Reduced noise pollution contributes to a more comfortable and safer working environment for machine operators. Regular maintenance and prompt upgrades ensure that the machine runs at peak efficiency, minimizing energy consumption and maximizing its useful life.

What are the Global Standards and Regulations Affecting Press Brake Axis Design?

The design and operation of press brake axes are governed by various international standards and regulations aimed at ensuring safety and performance . ISO standards provide a framework for ensuring uniformity in machine specifications and promoting reliable bending operations across different manufacturers and regions.

In the European Union, the CE certification is a mandatory requirement for machines, including press brakes, confirming that they meet stringent safety and environmental standards, including specific safeguards related to ram movement and other potential hazards.

In the United States, the ANSI B11.3 standard outlines safety requirements for press brakes, focusing on operational hazards and the design of axis configurations to minimize risks to operators.

The existence of these standards and regulations underscores the global commitment to ensuring the safety and reliability of press brake technology. Compliance with ISO standards promotes consistency and interoperability across different machines and manufacturers. The CE certification ensures that machines sold within the European Union meet an elevated level of safety and environmental protection.

Adherence to ANSI guidelines in the United States helps to create a safer working environment for press brake operators by setting up clear safety requirements for machine design and operation. Manufacturers must be aware of and follow these global standards and regulations to ensure that their press brakes are safe to run, meet the necessary performance requirements in different markets, and avoid potential legal and trade barriers. Compliance proves a commitment to safety and quality, which is essential for building trust with customers and running responsibly in the global marketplace.

What are the Technological Advances in Press Brake Axis Control?

The technology behind press brake axis control has advanced significantly in recent years, leading to improvements in accuracy, efficiency, and ease of use . Servo-hydraulic systems have appeared as a key advancement, allowing for more precise control over the Y1 and Y2 axes, resulting in improved bending accuracy and reduced energy consumption compared to traditional hydraulic systems.

Advanced back gauge systems, often incorporating Z1 and Z2 axes, enable more sophisticated workpiece positioning, easing the production of complex parts with greater precision.

The integration of smart sensors provides real-time monitoring of critical parameters such as ram movement, flange length, and bending angles, allowing for immediate adjustments and ensuring consistent results.

3D modeling integration with the CNC control system allows operators to simulate the bending process virtually before production, helping to find potential issues and perfect the bending sequence.

Furthermore, the increasing use of automation and artificial intelligence (AI) is leading to automated adjustments of axes like R, X, and V, improving productivity and material handling efficiency . Modern software and CNC systems have a profound impact on axis performance by providing real-time monitoring and automatic adjustments of bending angles and flange lengths. They also simplify the programming and operation of complex multi-axis configurations, making these advanced machines more accessible and improving the repeatability of bending operations.

These technological advancements are directly addressing the evolving needs of modern manufacturing for increased precision, higher efficiency, and reduced operational costs. Servo-hydraulic systems offer a significant improvement in energy efficiency and control accuracy. Advanced back gauge systems expand the range of parts that can be produced with high precision.

Smart sensors provide valuable real-time data that enables closed-loop control and minimizes errors. 3D modeling integration streamlines the programming process and reduces the risk of collisions or incorrect bends. Automation and AI further enhance productivity by automating repetitive tasks and optimizing bending parameters. The integration of sophisticated software and control systems simplifies the operation of even the most complex multi-axis press brakes, making them more user-friendly and accessible to a wider range of operators.

Conclusion: Perfecting Metalworking Processes Through Informed Axis Selection

In conclusion, the choice of the proper press brake axis setup is a critical determinant of efficiency and accuracy in metalworking operations . Each axis, whether the Y1 and Y2 controlling the ram's movement or the Z1 and Z2 governing the back gauge's lateral positioning, contributes uniquely to the quality of the final product . Advanced CNC systems and sophisticated software further enhance these capabilities, enabling the production of increasingly complex parts with greater precision and repeatability .

KRRASS offers a comprehensive range of press brakes, from 2 to 11 axes, each engineered for precision and reliability to meet the diverse needs of the metalworking industry . A well-informed decision about axis selection directly leads to more efficient and correct metalworking processes, ultimately contributing to higher quality products and improved profitability. Companies that invest the time and effort to thoroughly understand their press brake axis requirements and make informed purchasing decisions are more likely to achieve a significant competitive advantage overall. The choice of press brake axis configuration has a profound and lasting impact on the overall performance and success of any metalworking operation.