Welcome to the definitive guide that explores the differences, strengths, and applications of Press Brake and Shearing Machines in metalworking. Whether you’re in automotive, aerospace, construction, or running a sheet metal shop, this article is your roadmap to understanding which machine is best suited for your specific needs.

Importance of Choosing the Right Machine for Metalworking

Have you ever found yourself in the metalworking workshop, eyes darting from one massive machine to another, wondering which one is best for your specific project? Well, you're not alone. This decision is crucial, and it's more than just selecting the largest or the most expensive machine on the floor. The CNC Press Brake and the Hydraulic Shearing Machine are two giants in the realm of metal fabrication. But which one to choose? And why does it even matter?

Imagine buying an expensive sports car when all you needed was a reliable pickup truck for your business deliveries. Sounds impractical, right? The same principle applies to metalworking. You don't just need a machine; you need the right machine. With stakes high in terms of productivity, efficiency, and, most importantly, quality, the importance of making an informed choice is paramount.

Both the CNC Press Brake and the Hydraulic Shearing Machine are champions in their own right, each offering unique features and advantages. While one is known for its precision in bending and folding metal sheets, the other is renowned for its ability to cut and trim them with unmatched accuracy. So, every time you're thinking of working on a metal sheet, the key question to ask is: Am I looking to bend or cut? Your answer will guide your choice.

The realm of metalworking is vast and complex. Each project demands specific requirements and an unmatched level of precision. So, when it comes to investing in machinery, it's not just about money; it's about value. The value of ensuring that every piece of metal you work on is crafted to perfection, the value of ensuring that there's minimal wastage, and, most importantly, the value of knowing that you're delivering the best to your clients.

Types of Metalworking

Just like an artist has various forms of expression—be it painting, sculpting, or drawing—the world of metalworking is similarly diverse. There are several types of metalworking, and knowing which type you're involved in can help you decide between a CNC Press Brake and a Hydraulic Shearing Machine. So let's explore these different types, shall we?

Casting

This ancient technique involves melting metal and pouring it into molds. While it's a far cry from the sophisticated requirements of a CNC Press Brake or Hydraulic Shearing Machine, understanding the basics like casting can give you a broader perspective on metalworking as a whole.

Machining

Machining encompasses a variety of techniques that remove metal from a workpiece to achieve desired dimensions. This category includes processes like turning, milling, and drilling. Again, neither our press brake nor our shearing machine falls under this category, but hey, knowledge is power, right?

Welding

Welding is the process of fusing separate pieces of metal into one. It's a skill that's often complementary to the work done by a CNC Press Brake, especially if you're in the business of creating complex structures from metal sheets.

Sheet Metal Fabrication

Now we're talking! Sheet metal fabrication is where both the CNC Press Brake and the Hydraulic Shearing Machine shine. Whether it's cutting, bending, or shaping, these machines are your go-to equipment for dealing with sheet metal. This sector is ripe with opportunities for anyone keen on crafting anything from automotive parts to furniture.

Section 1: The Basics of Press Brake Machines

1.1 Definition and Functionality

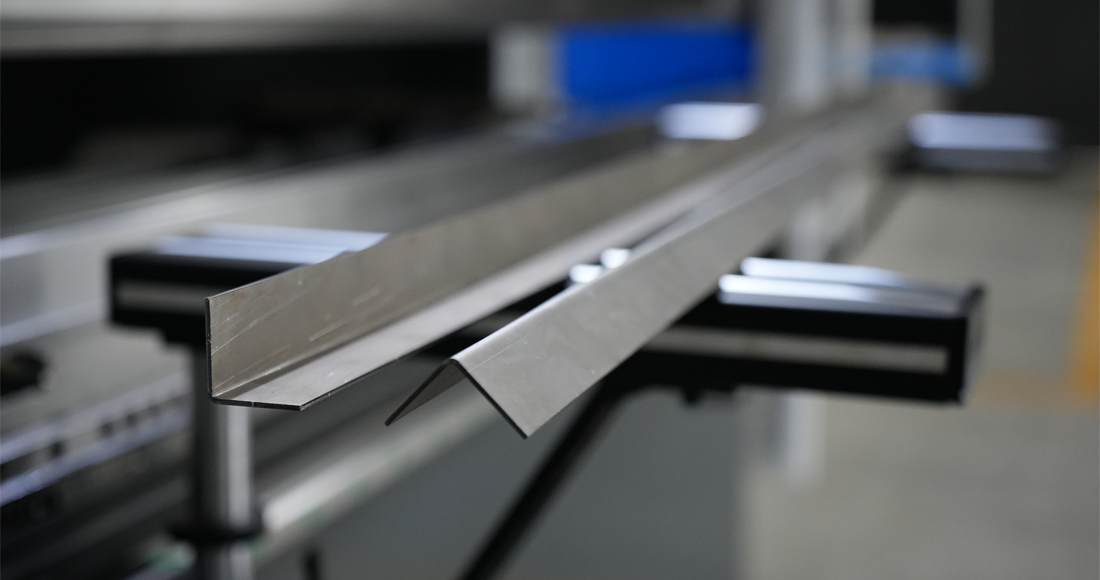

What is a CNC Press Brake anyway? Think of it as the artist's brush for metalworkers. In layman's terms, it's a machine designed for the primary purpose of bending and folding metal sheets. But it's not just any bending; it's precise, calculated, and intricate, allowing for various angles and dimensions. Whether you're crafting a simple metal box or designing complex parts for industrial machinery, a press brake is your trusty companion.

1.2 Types of Press Brakes

One size doesn't fit all, especially in the world of metalworking. When it comes to press brakes, you've got options:

- Mechanical Press Brakes: Older but reliable, these machines use a mechanical flywheel to store energy.

- Hydraulic Press Brakes: Modern and more versatile, these use hydraulic force for bending.

- CNC Press Brakes: The crème de la crème, offering programmable controls and ultra-precise bending.

1.3 Typical Applications

Where would you use a press brake? Almost anywhere where metal bending is required. From aerospace to automotive industries, and from construction to furniture making, press brakes have a wide range of applications.

1.4 Hydraulic vs Mechanical Press Brakes

The battle between hydraulic and mechanical press brakes is like choosing between a smartphone and a classic flip phone. Both have their merits. Hydraulic press brakes offer more control and are generally easier to operate. Mechanical press brakes, though a bit outdated, are robust and built to last. Your choice depends on your specific needs.

1.5 Key Features of Press Brake Machines

When shopping for a press brake, keep an eye out for features like:

- Backgauge: Allows for precise depth gauging.

- Crowning Systems: Helps in compensating for material variability.

- Safety Features: Laser guards, foot pedals, etc., to ensure operator safety.

Section 2: Understanding Shearing Machines

2.1 What is a Shearing Machine?

So you've heard about shearing machines, but what exactly are they? Imagine you're a tailor. You wouldn't use scissors designed for paper to cut through heavy fabric, right? Similarly, a shearing machine is your specialized 'scissors' in the metalworking industry. Unlike press brakes, which are more about bending, a Hydraulic Shearing Machine is all about cutting. It slices through metal sheets like a hot knife through butter, making it an indispensable tool in many industries.

2.2 Types of Shearing Machines

If you thought one shearing machine could do it all, think again. There are several types to meet the various needs of the metalworking world:

- Guillotine Shears: These work just like a guillotine, with a descending blade.

- Swing Beam Shears: These have a pivoting blade, often used for thicker metals.

- Alligator Shears: Perfect for cutting through waste metal and other scrap materials.

2.3 Typical Applications

So where would you use a shearing machine? These versatile machines find homes in a multitude of industries. Whether it's aerospace, automotive manufacturing, construction, or even art installations, the ability to cut precise metal shapes is invaluable.

2.4 Guillotine vs Swing Beam Shears

It's like choosing between a sedan and an SUV; both are cars but serve slightly different purposes. Guillotine shears are fantastic for precision and are generally more versatile. Swing Beam Shears are your go-to for heavy-duty cutting where brute force is more important than finesse. Knowing your project's requirements will help you make the best choice.

2.5 Important Features of Shearing Machines

Don't overlook these crucial aspects when shopping for a shearing machine:

- Blade Quality: A high-grade blade ensures longevity and precise cuts.

- Clamp Mechanisms: These hold the metal sheet in place, ensuring clean cuts.

- Safety Features: Emergency stops, light guards, etc., to protect the operator.

Section 3: Press Brake vs Shearing Machine: A Detailed Comparison

3.1 Comparing Bending Capabilities

Let's kick things off with bending capabilities. Press Brakes excel here. You're looking at a machine designed to make complex bends with precision. But let's not entirely rule out shearing machines. Some advanced models come with basic bending options, but when it comes to bending versatility, a CNC Press Brake takes the cake.

3.2 Assessing Cutting Capabilities

Now, if you're on the flip side of the coin and need more cutting than bending, the Shearing Machine is your MVP. It cuts swiftly and efficiently, while a Press Brake might struggle or not even have the option.

3.3 Versatility: Range of Shapes and Sizes

In terms of versatility, the Press Brake is like the Swiss Army knife of metalworking, capable of creating multiple shapes and sizes. A Shearing Machine has limitations and is best suited for straight-line cuts.

3.4 Material Considerations

Metals Best Suited for Each Machine

Press brakes work best with softer metals like aluminum, while shearing machines can tackle harder metals like stainless steel more effectively.

Strength and Durability Factors

Shearing machines are built for brute force and can handle tougher materials. Press brakes, on the other hand, prioritize precision over raw power.

Cost Implications

Generally, a CNC Press Brake with its multitude of features will be more expensive than a standard shearing machine.

3.5 Operational Efficiency

Time and Labor Investments

Shearing machines are generally faster and require less skilled labor. Press brakes may need experienced operators to harness their full potential.

Energy Consumption

Shearing machines usually consume less energy, thanks to their straightforward operation. CNC Press Brakes, with their advanced functionalities, tend to consume more.

Maintenance Requirements

Expect more frequent maintenance checks for press brakes due to their complex components. Shearing machines are comparatively easier and less expensive to maintain.

3.6 Quality of Output

Accuracy and Precision

Press brakes win in the accuracy department. They can be calibrated for minute adjustments, unlike shearing machines that may leave rough edges.

Surface Finish Quality

Shearing machines may sometimes leave burrs or rough edges, requiring additional post-processing. Press brakes generally offer a cleaner finish.

Post-processing Requirements

In most cases, materials cut using a press brake are usually ready for the next stage of production without the need for further post-processing, unlike those cut by shearing machines.

Section 4: Industry-Specific Considerations

Automotive Industry

In the automotive sector, both Press Brakes and Shearing Machines are equally essential. While Press Brakes can expertly handle the intricacies of automotive design, Shearing Machines are quintessential for cutting through robust metal sheets. Press Brakes often provide the level of precision necessary for components like car panels, while Shearing Machines are great for quickly sizing larger sheets that might be further processed.

Aerospace Industry

In the aerospace sector, precision isn't just a luxury; it's a mandate. The CNC Press Brake is often the machine of choice for its unparalleled accuracy. Shearing Machines are also utilized but usually for initial cuts before finer adjustments are made using Press Brakes.

Construction Sector

The construction industry is all about scale and speed, making the Shearing Machine an indispensable asset. It's excellent for cutting large metal sheets for building structures. On the other hand, Press Brakes are often used for more specialized tasks like creating custom brackets or supports.

Sheet Metal Shops

Sheet metal shops generally benefit from having both machines. A Shearing Machine can quickly trim down materials, while a Press Brake can make intricate bends and folds. It's the best of both worlds, serving a wider range of customer requirements.

Conclusion

We've dissected the intricacies of Press Brakes and Shearing Machines so you can make an informed decision for your business. Each has its merits, but the best fit depends on your industry and specific needs. For state-of-the-art Press Brake and Shearing Machines, look no further than Krrass, a leading manufacturer in the field. Visit our website at https://www.krrass.com/ to explore our top-of-the-line offerings.

Read More: