Efficient Laser Cutting Machine, Efficient Fiber Laser Cutting Machine in 2025

$17,600.00 Original price was: $17,600.00.$15,800.00Current price is: $15,800.00.

Model: RAS-3015-Smart 3000W

Category: Fiber Laser Cutting Machine

Brand Name: KRRASS

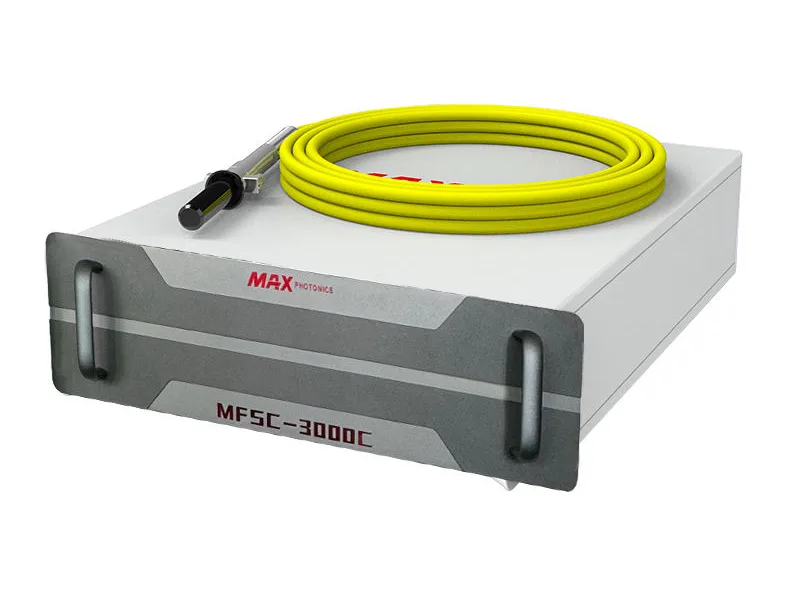

Laser Source: Max China

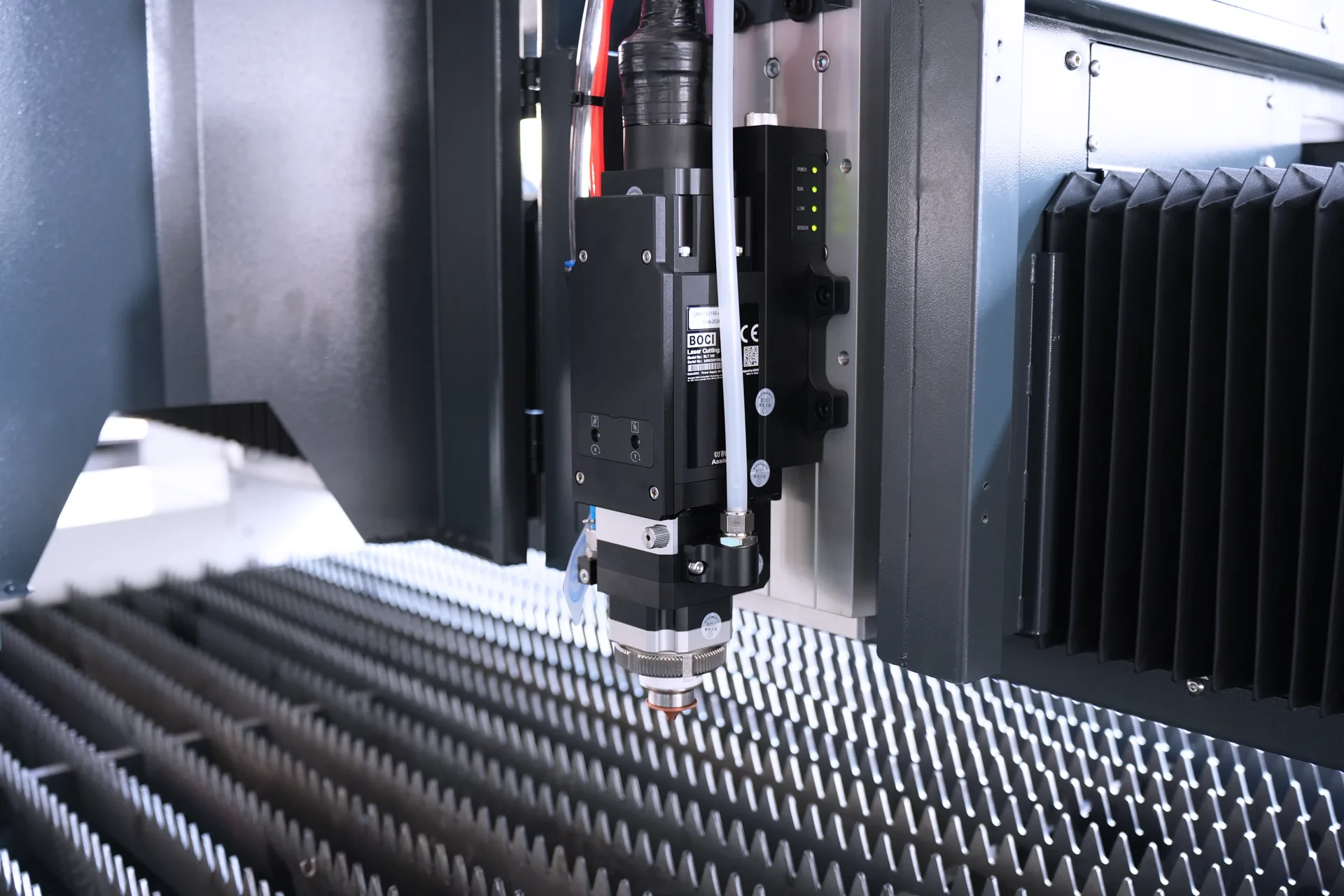

Laser Head: BLT310

Control system: FSCUT2000E

Working Area: 3000mm * 1500mm

HS Code: 8456110090

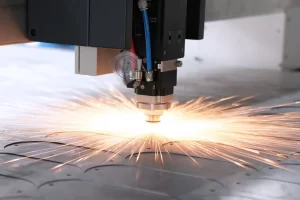

Application: Efficient CNC Fiber Laser Cutting Machine, 3KW Efficient Fiber Laser Cutting Machine for Sheet Metal

Technologyies

| Laser Source: | Max China MFSC 3000W |

| Laser Head: | BLT310 |

| Control system: | FSCUT2000E |

| Working Area: | 3000mm * 1500mm |

| Operating Voltage: | 380V 50Hz |

| Power: | 3000W |

| Length* Width* Height: | 4800mm * 2265mm * 1900mm |

Configurations

Main Feature

KRRASS’s RAS-3015 Smart 3000W Efficient Laser Cutting Machine is for metal fabrication, including steel designed, aluminum, titanium, alloy, brass, copper, and iron, with different laser powers (1500W, 2000W, 3000W, 4000W, 6000W, 12000W, 20KW, 30KW, 40KW). The affordable 3000W fiber laser cutting machine is for sale at a low price, with the best fiber laser-cutting system service and support.

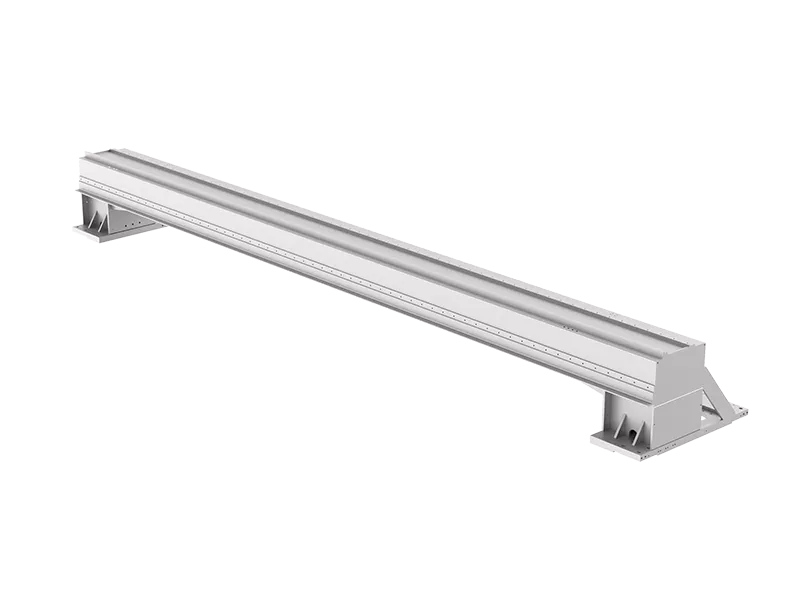

Upgraded Matrix Machine Bed with Level-up Rigidity

Brand-new matrix machine and welding design of the cross-section improve the rigidity of entire machine bed structure significantly and decrease the negative influence on machine bed.

Max China MFSC 3000W Laser Source

MFSC 3000W Single Module CW Fiber Laser, based on modular design,has excellent beam quality and high stability, which structure is compact and water-cooling. The laser can be adjusted continuously, and the beam is transmitted be fiber and QBH connector, which is ideal for laser cutting, laser welding, etc . The laser is very suitable for system intergration with robot or machine tool, and is widely used for laser cutting, welding, 3D printing, electronics, automobile parts,aerospace, etc.

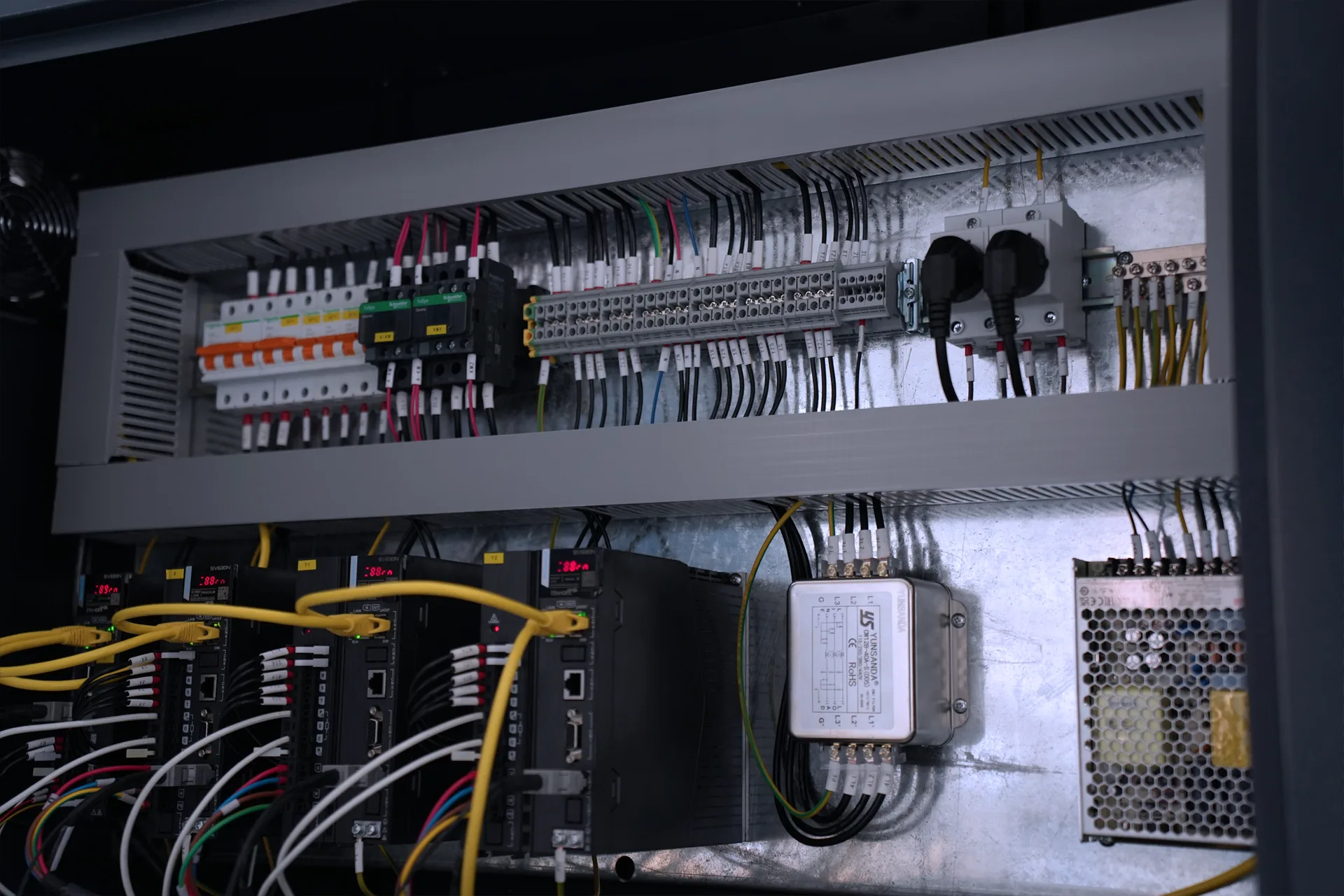

Bus Control System FSCUT2000E

It enables data transmission via EtherCAT bus and features fast speed and stability. This system is easy to be operated and rich in functions. Even green hands can cut high-quality samples.

BOCHU BLT310 Smart Cutting Heads

- Pressure Sensor: One-click pressure calibration ensures continuity of quality. Gas pressure detection before turning on laser helps to prevent windows breakdown caused by insufficient pressure.

- Amplifier Sensor: Integrated capacitance amplifier sensor makes a more precise and stable following.

- Fast Focusing: Focal position vertically adjusted by collimating lens, realizing higher efficiency.

- Collision Protection: Protective Screws keep cutting head from damage. No time wasting on Depot Repair.

- Water Cooling: The cutting head water circuit is protected with an anti-corrosion coating to prevent corrosion over prolonged use, which can lead to blockages and reduced cooling effectiveness.

- Protective Window Temperature Monitoring: Protective Window Temperature Sensor: Real time temperature monitoring to limit risk of protective window shattering, enhance processing stability.

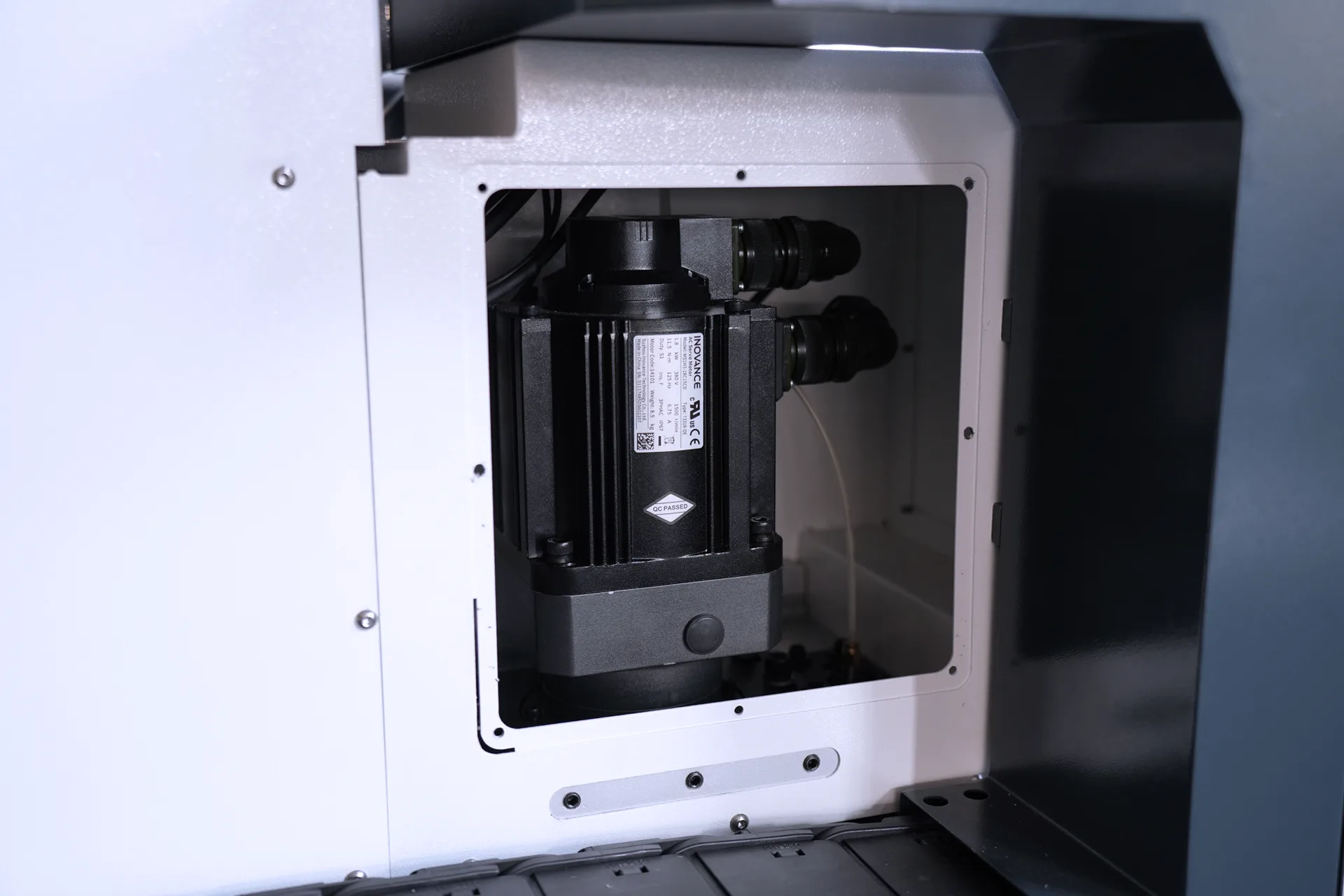

INOVANCE High Speed Servo Motor And Drive

- Y-axis: Two 1.8KW INOVANCE high speed servo motor with MOTOREDUCER reducers;

- X-axis: One 1.3KW INOVANCE high speed servo motor with MOTOREDUCER reducers;

- Z-axis: One 0.4KW INOVANCE high speed servo motor.

This configuration enables fast and precise movement of the Efficient Laser Cutting Machine's crossbeam, with acceleration up to 1.4G.

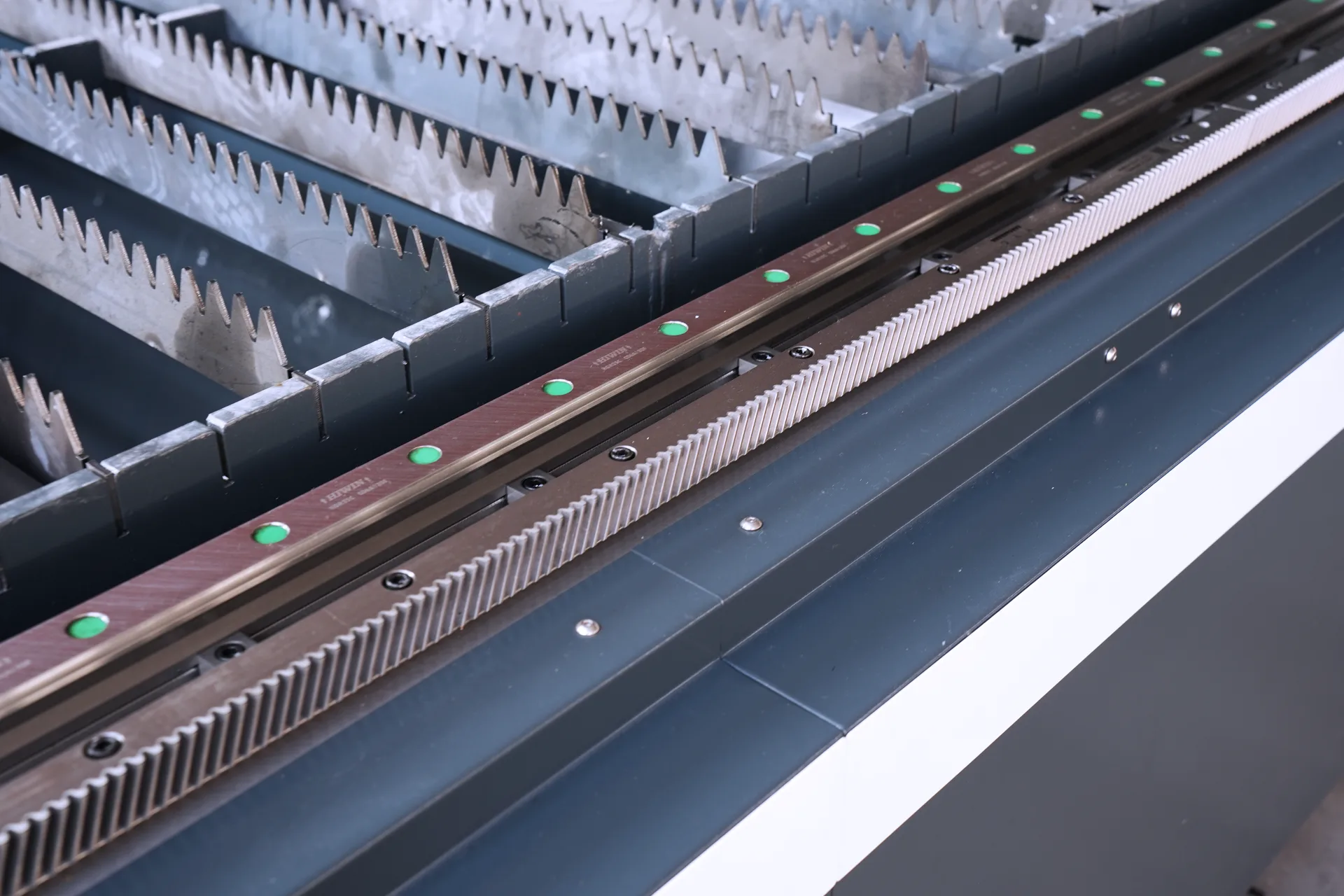

HIWIN High Precision Linear Guide Rail and YCC Precise Rack

- Y-axis: 2 HIWIN high precision linear guide rails with a width of 35mm with YCC precise rack;

- X-axis: 2 HIWIN high precision linear guide rail with a width of 25mm with YCC precise rack;

Brand-new Aluminum Beam

The new fifth-generation 6-series aluminum beam has 20% less weight and 15% more torsional resistance than the previous generation. Lightweight design beams play a high dynamic performance of the equipment to improve processing efficiency.

Water Cooler

A water cooler in the 3000W Efficient Laser Cutting Machine regulates the temperature of the laser and components, preventing overheating and ensuring optimal performance and longevity.

Schneider Electric

High quality electric parts can perform well even the electricity is not stable and customers can easily get the replacement anywhere in the word.

Air Conditioning for Electrical Cabinets

In order to ensure the stability of the temperature and humidity of the efficient laser cutting machine light source, we have equipped its electrical cabinet with a dedicated air conditioner to ensure that the laser light source can work for a long time in a constant temperature and humidity environment.

3000W Efficient Laser Cutting Machine Material Thickness

| Thickness(mm) | Speed(m/min) | Focus position | Cutting height(mm) | Gas | Nozzle type | Pressure(bar) | Cutting effect | |

|---|---|---|---|---|---|---|---|---|

| Carbon steel (Q235B) | 1 | 59 | 0 | 0.5 | N2 | Single:1.0 | 12~16 | Bright surace |

| 2 | 28 | -1~-1.5 | 0.5 | Single:2.0 | 12~16 | |||

| 3 | 4 | 4.5~5.5 | 0.8 | O2 | Double:1.2 | 0.6~0.9 | ||

| 4 | 3.5 | 4.5~5.5 | 0.8 | Double:1.2 | 0.6~0.9 | |||

| 6 | 2.7 | 4.5~5.5 | 0.8 | Double:1.2 | 0.6~0.9 | |||

| 8 | 2.2 | 4.5~5.5 | 1.5 | Double:4.0 | 0.6~0.9 | |||

| 10 | 1.5 | 2~3 | 1.5 | Double:4.0 | 0.6~0.9 | Matte surface | ||

| 12 | 1 | 2~3 | 1.5 | Double:4.0 | 0.6~0.9 | |||

| 14 | 0.95 | 2~3 | 1.5 | Double:4.0 | 0.6~0.9 | |||

| 16 | 0.85 | 2.5~3.5 | 1.5 | Double:4.0 | 0.6~0.9 | |||

| 18 | 0.72 | 2.5~3.5 | 1.5 | Double:4.0 | 0.6~0.9 | |||

| 20 | 0.65 | 2.5~3.5 | 1.5 | Double:4.0 | 0.6~0.9 | |||

| 22 | 0.55 | 2.5~3.5 | 1.5 | Double:4.0 | 0.6~0.9 | |||

| 25 | 0.5 | 2.5~4 | 1.5 | Double:4.0 | 0.6~0.9 | |||

| Stainless steel (SUS304) | 1 | 0 | 0.5 | N2 | Single:1.0 | 12~16 | No slag | |

| 2 | 0~-0.5 | 0.5 | Single:2.0 | 12~16 | ||||

| 3 | 12 | -1~-1.5 | 0.5 | Single:2.0 | 12~16 | |||

| 4 | 4.3 | -3.5~-4 | 0.5 | Single:3.5 | 12~16 | |||

| 6 | 1.8 | -5~-6 | 0.5 | Single:3.5 | 16~18 | |||

| 8 | 1.2 | -6.5~-7 | 0.5 | Single:3.5 | 16~18 | |||

| 10 | 0.9 | -7.5~-8.5 | 0.5 | Single:3.5 | 16~18 | A small amount of slag | ||

| 12 | 0.4 | -9~-10 | 0.5 | Single:4.0 | 16~20 | A small amount of dross | ||

| Aluminum (6061) | 1 | 37~40 | 0 | 0.5 | Air | Single:1.0/1.2/1.5 | 12~16 | |

| 2 | 20~22 | 0~-0.5 | 0.5 | Single:1.5/2.0 | 12~16 | |||

| 3 | 8~9 | 0~-0.5 | 0.5 | Single:2.0/2.5/3.0 | 12~16 | |||

| 4 | 5~5.2 | -1~-1.5 | 0.5 | Single:3.0 | 12~16 | |||

| 6 | 2.2~2.5 | -2~-3 | 0.5 | Single:3.5/4.0 | 12~16 | |||

| 8 | 1~1.2 | -3~-4 | 0.5 | Single:4.0 | 16~18 | |||

| 10 | 0.5~0.6 | -5~-5.5 | 0.5 | Single:4.0 | 16~18 | |||

| Brass | 1 | 15~17 | 0 | 1.5 | Air | Single:1.0/1.2/1.5 | 12~16 | |

| 2 | 18~20 | 0~-0.5 | 2.5 | Single:1.5/2.0 | 12~16 | |||

| 3 | 7~7.5 | 0~-0.5 | 3.5 | Single:2.0/2.5/3.0 | 12~16 | |||

| 4 | 4~4.5 | -1~-1.5 | 4.5 | Single:3.0 | 12~16 | |||

| 6 | 2.0~2.2 | -2~-3 | 5.5 | Single:3.5/4.0 | 12~16 | |||

| 8 | 0.9~1.1 | -3~-4 | 6.5 | Single:4.0 | 16~18 | |||

| 10 | 0.5~0.6 | -5~-5.5 | 7.5 | Single:4.0 | 16~18 |

What is this Machine Used for?

Warranty

30-DAY MONEY BACK GUARANTEE

You should feel completely satisfied with your KRRASS Fiber Laser Cutting Machine purchase, and your peace of mind is a significant part of that process. We want you to feel the same confidence in your new KRRASS machine that we do, which is why every Press Brake purchase includes our Hassle-Free KRRASS 30-Day Return option in order to fully experience and evaluate their new KRRASS machine. It allows you to return or exchange your KRRASS purchase, for any reason, within 30 days of initial purchase. Refunds are simple and are issued once the original machine and all accompanying accessories have been returned. The refund or exchange will be issued minus the 15% restocking fee for items & accessories, 25% KRRASS Fiber Laser Cutting Machine Series customization fee, and shipping or handling costs are not included. Click here for details

2-YEAR LIMITED MACHINE WARRANTY

2 years Bumper to Bumper machine warranty for all machine mechanical and electrical components. (Except consumables parts) The Company represents and warrants that the KRRASS All Series of products will perform according to the warranty policy stated above from date of invoice. Products will be free from defects in materials and workmanship under normal use and service for the stated period. KRRASS has the responsibility to offer a timely solution and/or repair if deemed inoperable or defective by KRRASS Repair & Support Specialists. Clients are obligated to show proof of any such claims of machine parts or operational defects. Click here for details

Reviewed by 6 users

Related products

Related products

-

Sale!

Sale!

12000W Fiber Laser Cutting Machine For Metal

5.00 out of 5$48,800.00Original price was: $48,800.00.$43,900.00Current price is: $43,900.00. Add to cart -

Sale!

Sale!

1.5KW Fiber Laser Cutting Machine, 1500W Sheet Metal Laser Cutting Machine Price

5.00 out of 5$16,000.00Original price was: $16,000.00.$14,400.00Current price is: $14,400.00. Add to cart -

Sale!

Sale!

3000W Fiber Laser Cutting Machine, 3KW Fiber Laser Cutting Machine for Metal

5.00 out of 5$17,600.00Original price was: $17,600.00.$15,800.00Current price is: $15,800.00. Add to cart -

Sale!

Sale!

6KW Fiber Laser Cutting Machine, 6000W Sheet Metal Laser Cutting Machine Price

5.00 out of 5$25,900.00Original price was: $25,900.00.$23,300.00Current price is: $23,300.00. Add to cart

Leave feedback about this