WC67K-100T3200 Press Brake Machine with Estun E310P Control and Manual Crowning

$17,499.00 Original price was: $17,499.00.$15,899.00Current price is: $15,899.00.

Model: WC67K-100T3200

Category: NC Press Brake

Brand Name: KRRASS

Bending Pressure: 1000KN

Bending Length: 3200Mm

Controller: ESTUN E310P

HS Code: 8462299000

Application: 100Ton NC Press Brake, 3200mm long, can bend stainless steel, iron plates, aluminum plates, and can produce different complex products.

Technologyies

| Bending Pressure: | 1000KN |

| Bending Length: | 3200mm |

| NC Control Axes: | Y+X+R+Z1, Z2+W Crowning |

| Main Motor: | 7.5KW |

| Operating Voltage: | 380V 50Hz |

| CNC System: | E310P |

| Length* Width* Height: | 3700mm * 1500mm * 2500mm |

Configurations

Main Feature

The Press Brake Machine with E310P Controller with its easy-to-use control unit, rigid body frame, flawless design, high efficiency, multiple tool usage solutions, top CE safety standards, and a suitable price range make it the best-in-class world leader. It is ideal for bend-sensitive, energy-efficient solutions.

- Simple and solid Hydraulic Press Brake

- Work area can be customized and all types of tool clamping can be installed

- Tailored-made Hydraulic Press Brake

ESTUN E310P Control

- 4 axes are supported, viz, X-axis, Y-axis, R-axis and C-axis.

- The back gauge can be controlled in a high-accuracy since the servo systems control X-axis and R-axis.

- Automatic calculation of the block position, according to the bending angle, material, thickness and mold parameters.

- The back gauge can be controlled in a high-accuracy since the servo systems control X-axis and R-axis.

- Optional hydraulic or mechanical to control the C-axis.

- Program in absolute value or angle.

- Materials and die informations are programable.

- Language setting and unit setting.

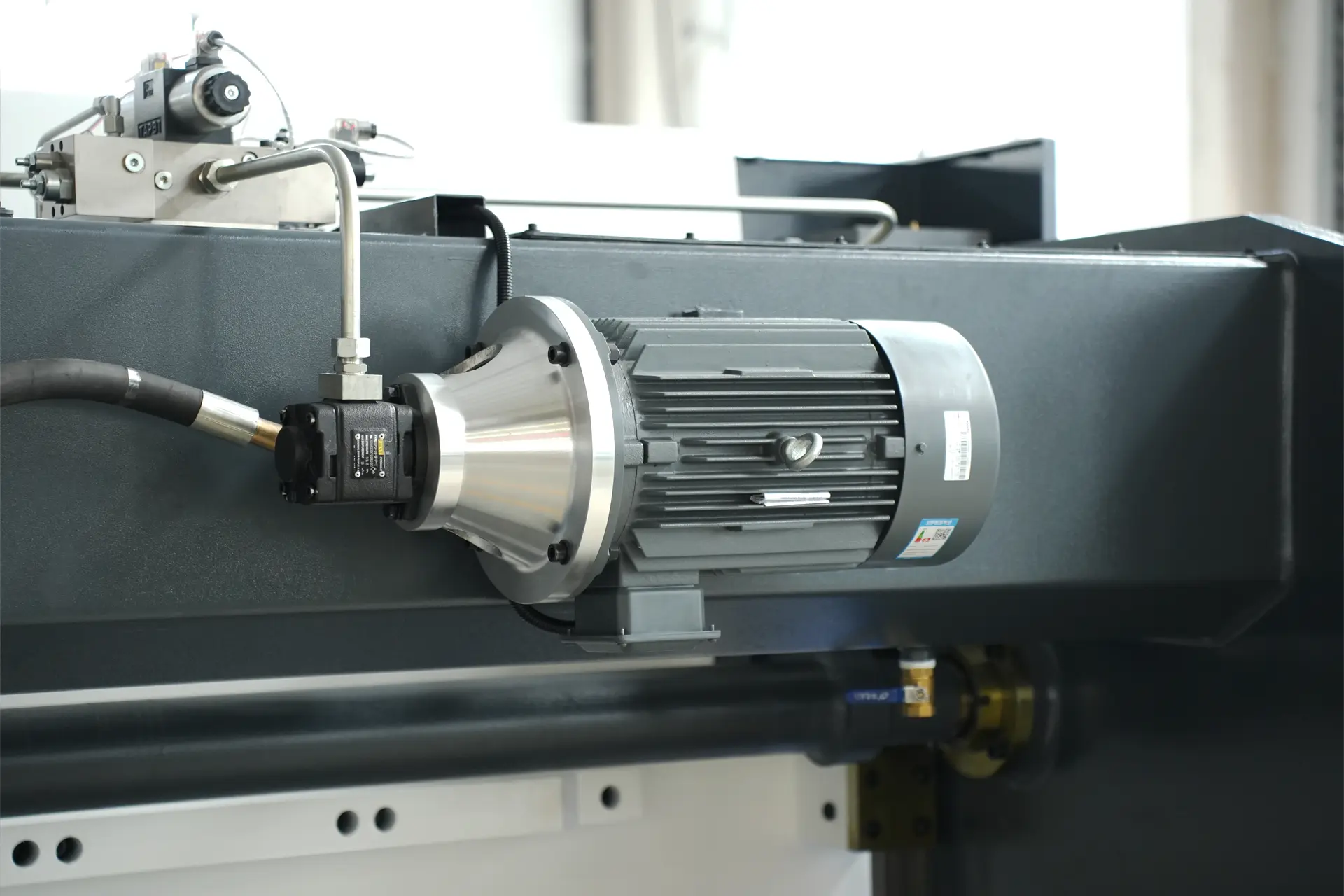

German Siemens main motor

The German famous brand motor increases the service life of the Press Brake Machine and keeps the machine working in a low-noise environment.

American FIRST oil pump, low noise, long life.

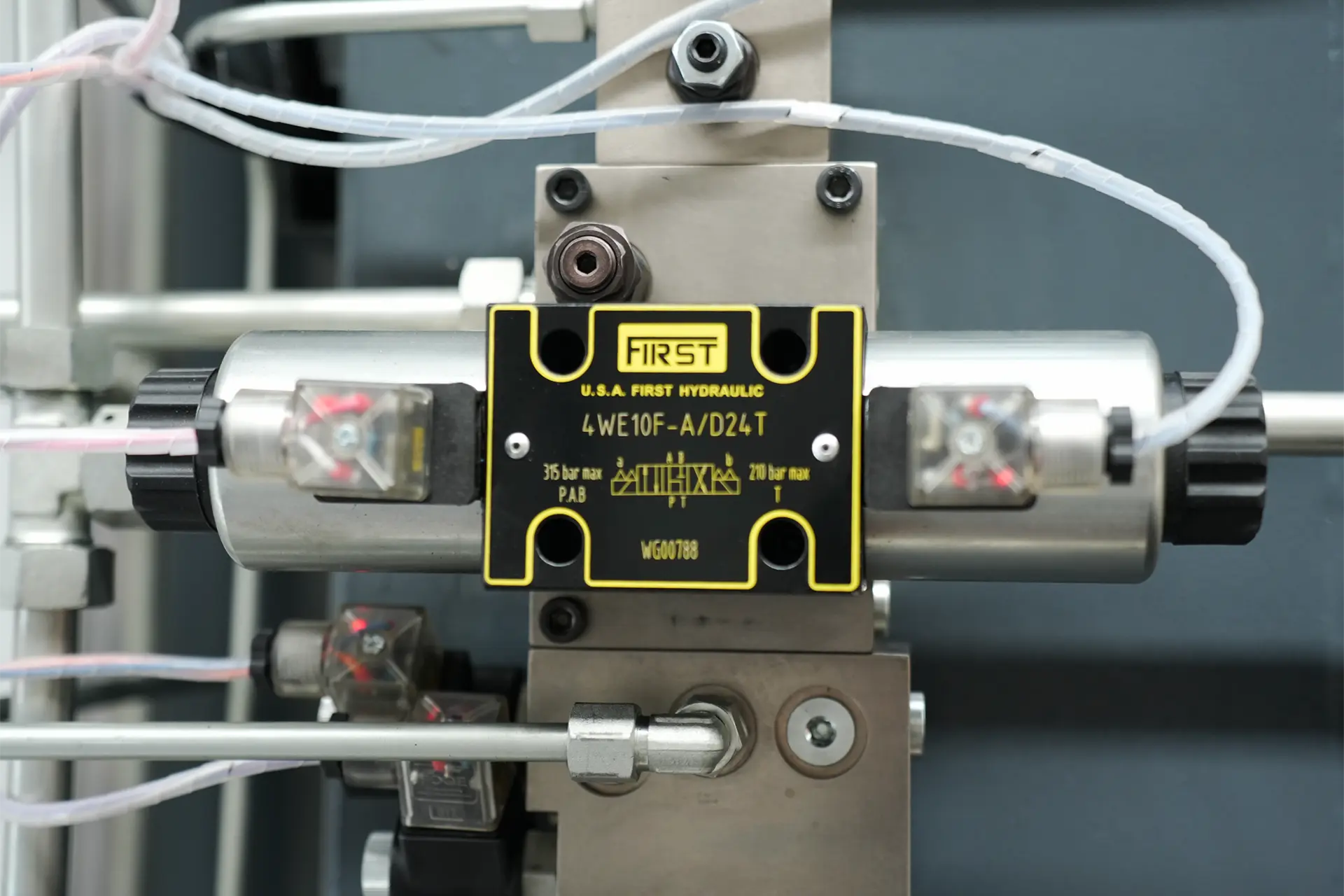

FIRST hydraulic valves

The valve group from USA FIRST is used to ensure more accurate bending accuracy and service life.

The hydraulic pipes are made of the German EMB brand, which is guaranteed to never leak oil.

Schneider Electric

High quality electric parts can perform well even the electricity is not stable and customers can easily get the replacement anywhere in the word.

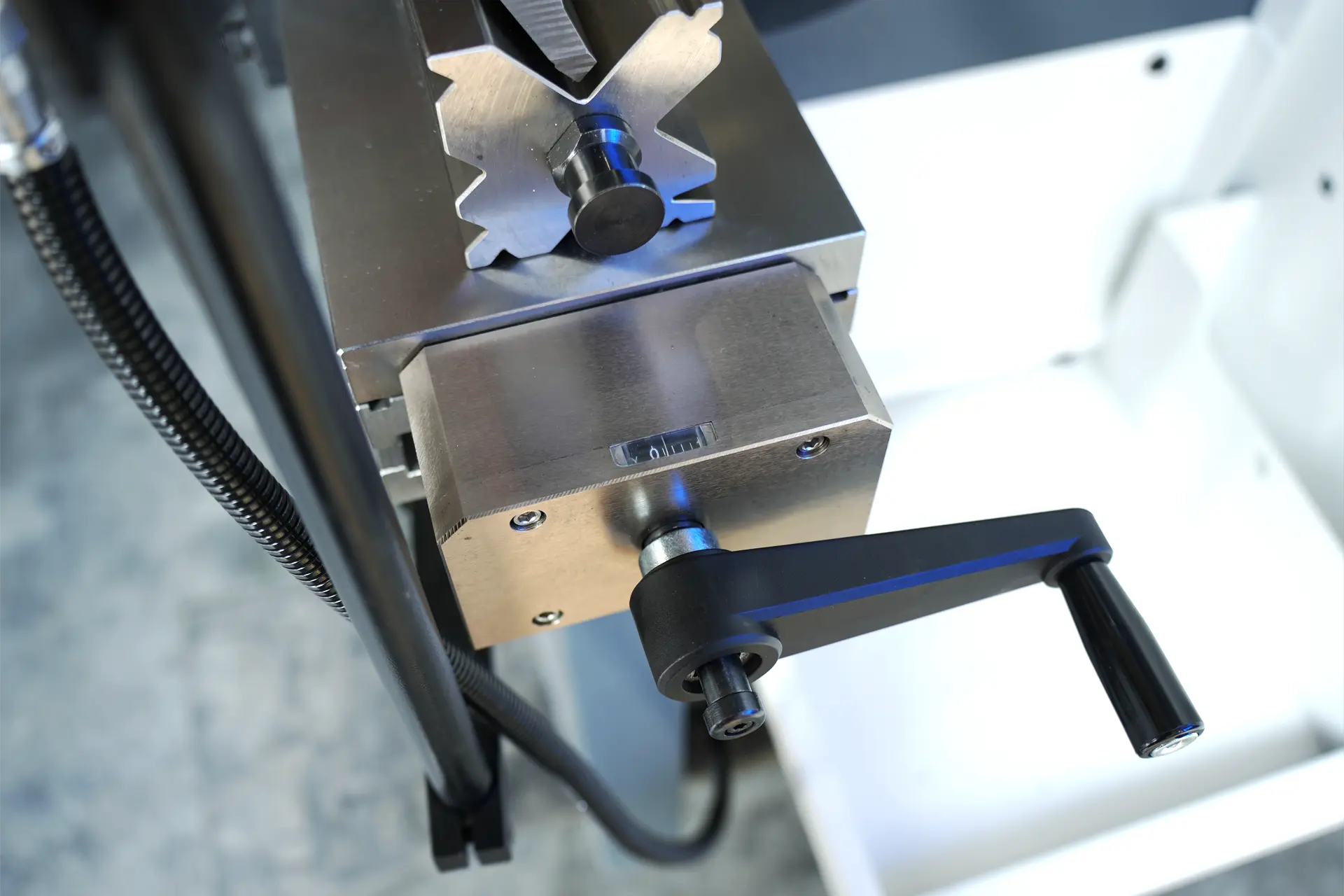

Manual Upper Tool Clamping

Our Press Brake Machine uses raw material provided by qualified suppliers, and the chemical composition corresponds to international standards. Therefore, the raw material yield and tensile strength are guaranteed. The materials are standardized with an 8.4 x 3.5 mm safety groove, which prevents the tool from falling out.

Photoelectric Safety Protection System (Optional)

The whole machine is equipped with photoelectric safety protection systems at the front and rear to ensure efficient production and the personal safety of operators.

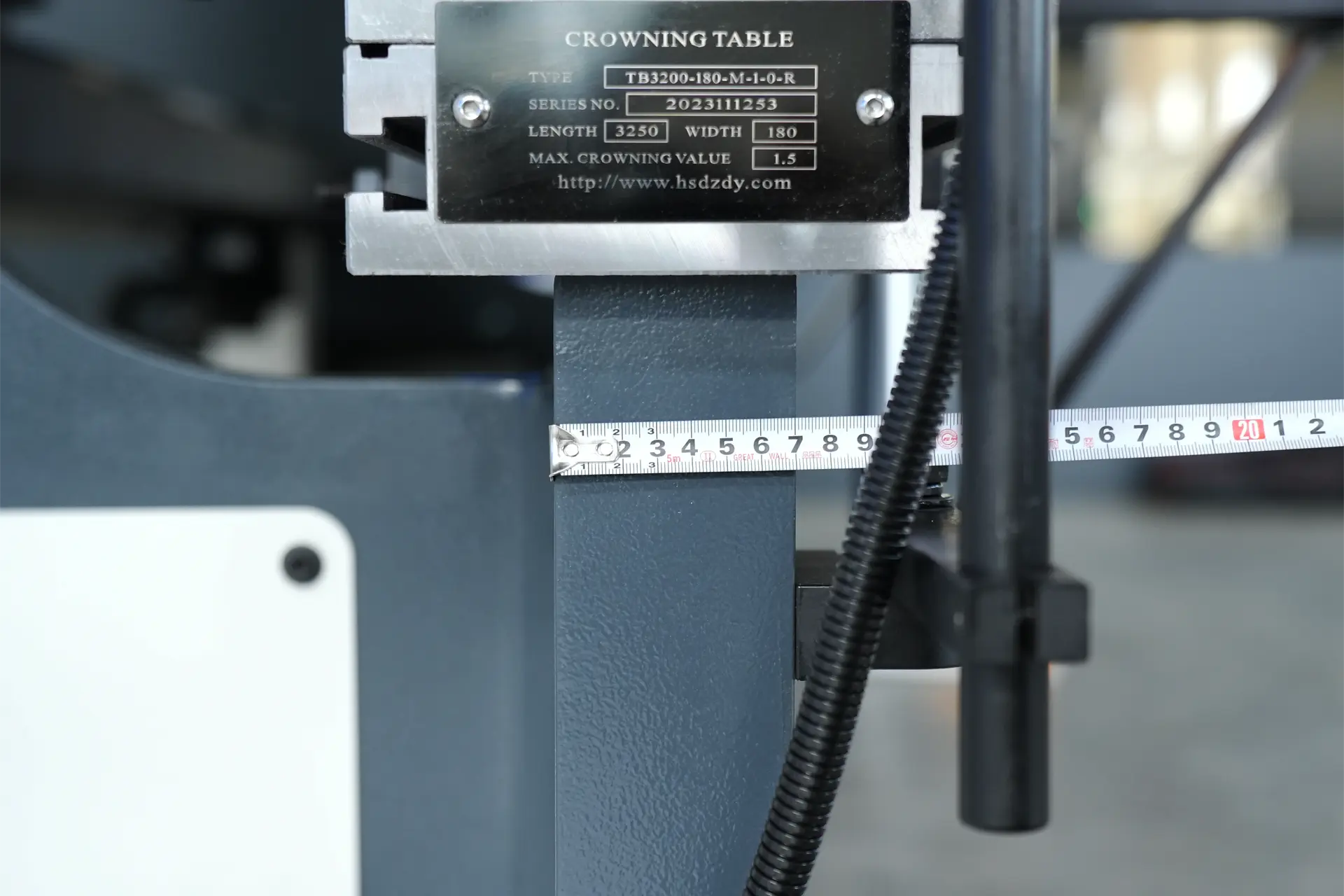

Manual Crowning System (Optional)

The elastic deformation produced in the middle of the slider of the nc press brake and the middle of the worktable causes the angle of the entire length to be inconsistent during bending, which is an important factor affecting the bending accuracy. Therefore, our 300T press brake is equipped with this function as standard.

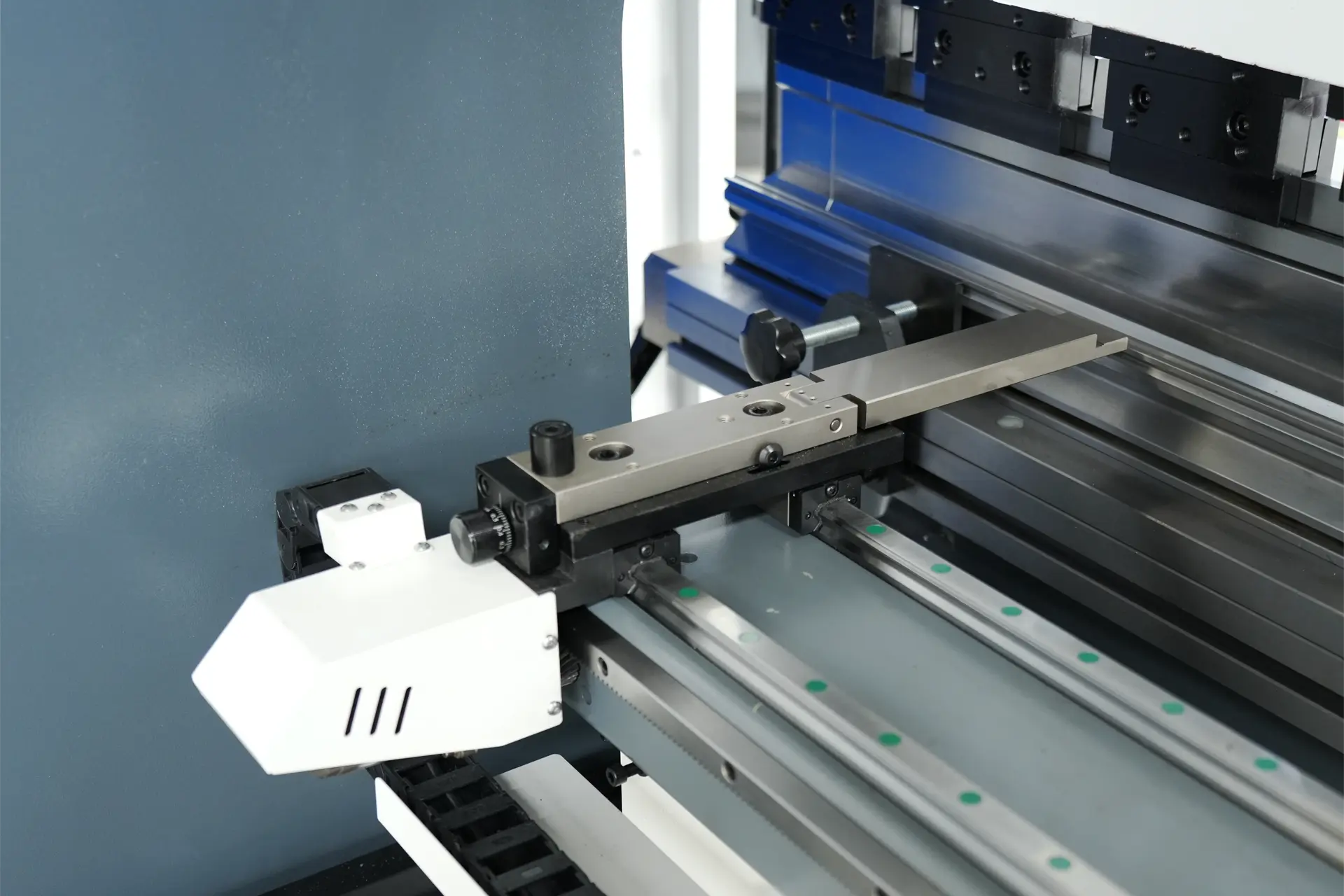

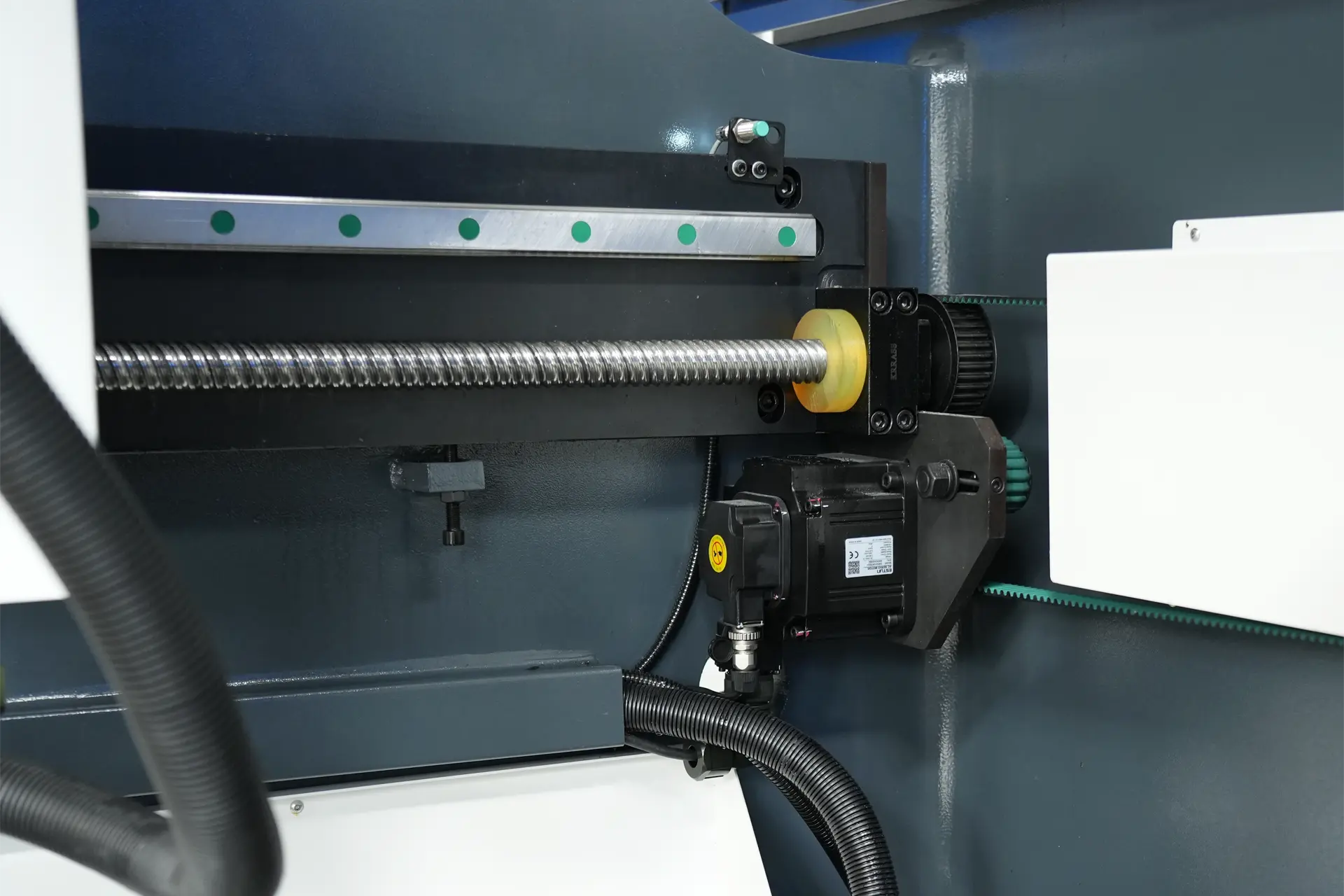

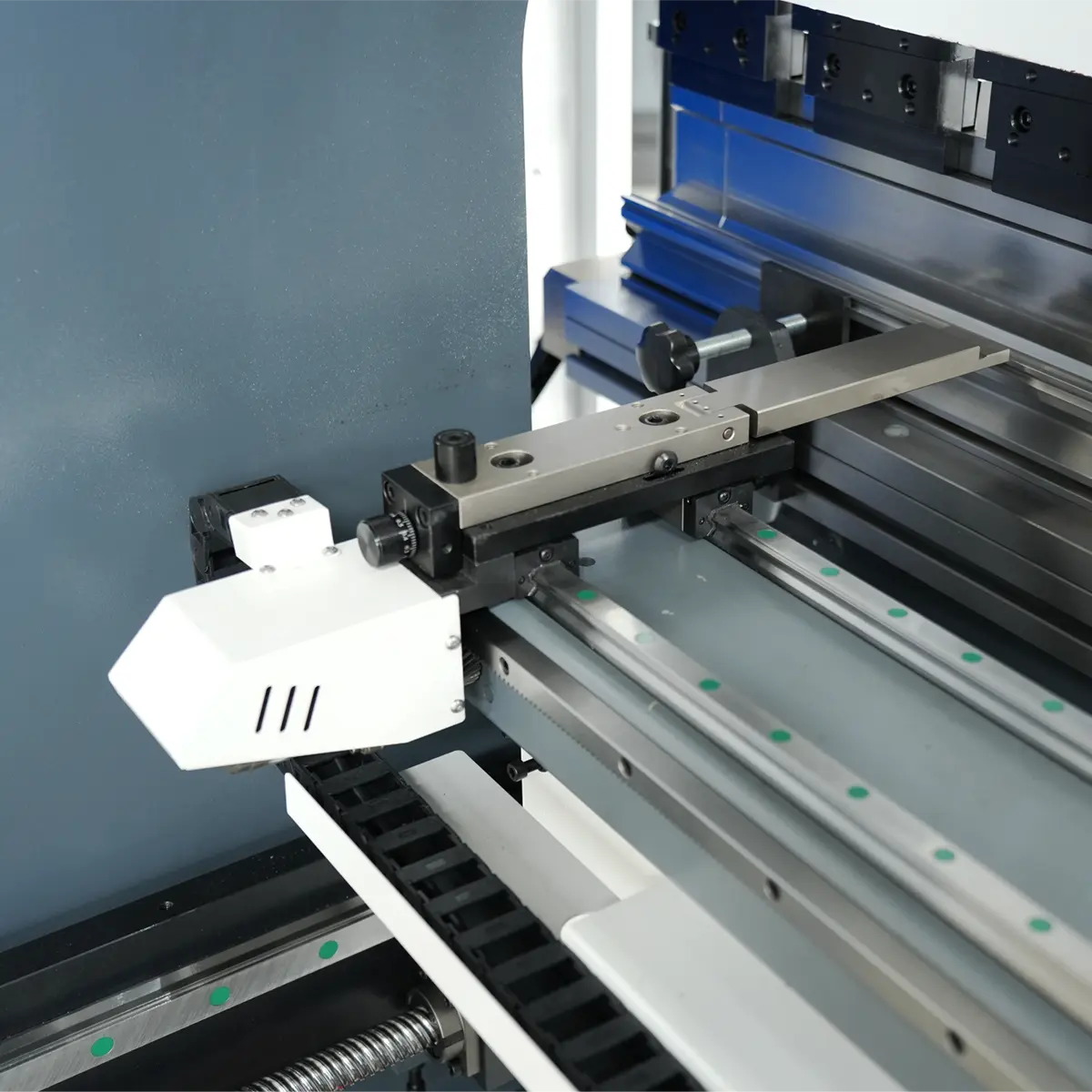

4-Axis Backgauge with X, R-Axis and Manual Electric Z1, Z2-Axis

- SHAC Ball screws and linear guide on X, R-axis

- Axis X speed 500 mm/s

- Manual Z1, Z2-axis with SHAC linear guide

- Electric Z1, Z2-axis is independently controlled, making operation more convenient (optional)

- Mechanical accuracy ± 0.01 mm

- Fingers with double stop and micrometric adjustment

X-axis Ball Screw Linear Guide and Servo Motor

- Precision: Ball screws offer improved precision, reduced energy consumption, and lower maintenance requirements.

- Responsiveness: Ball screws deliver very smooth motion.

- Friction: Ball screws rely on recirculating balls to alleviate friction instead of lubricants.

- High output power: Relative to their size and weight

- Closed-loop control: Ensures greater accuracy

- Quiet operation: Little sound noise

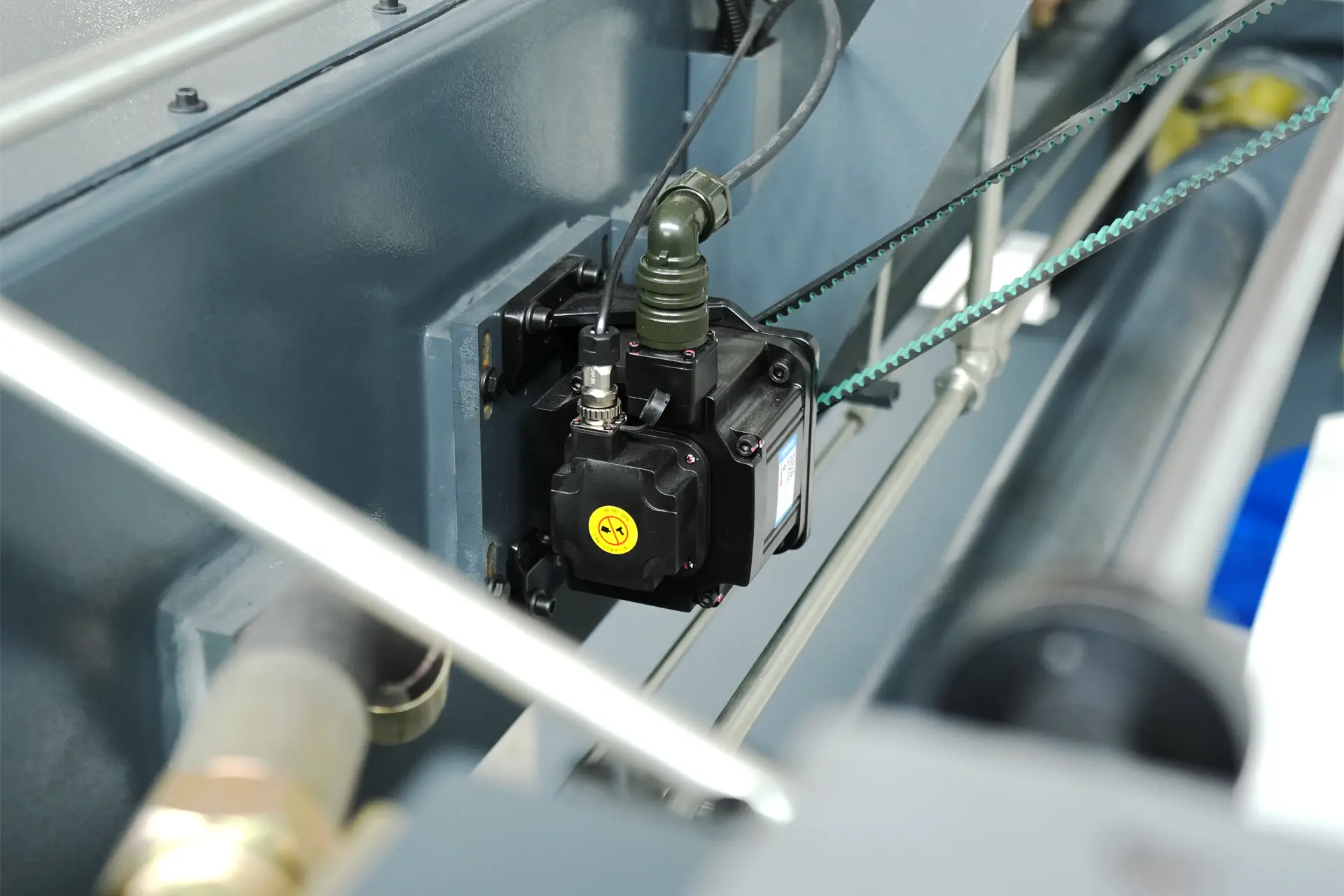

Y-axis Servo Motor

Servo motors have several advantages, including:

- High efficiency: Can approach 90% at light loads

- High output power: Relative to their size and weight

- Closed-loop control: Ensures greater accuracy

- Quiet operation: Little sound noise

- High reliability: Highly reliable

- High ratio of torque to inertia: Can provide as much as 50% more torque in many applications

- High precision: Can precisely actuate, hold, and speed up positions, torque, and speeds in fractions of seconds

South Korea KACON Foot Switch with Z1, Z2-axis Control

South Korea brand foot switch is movableand can stop the Press Brake Machine anytime by theemergency button.

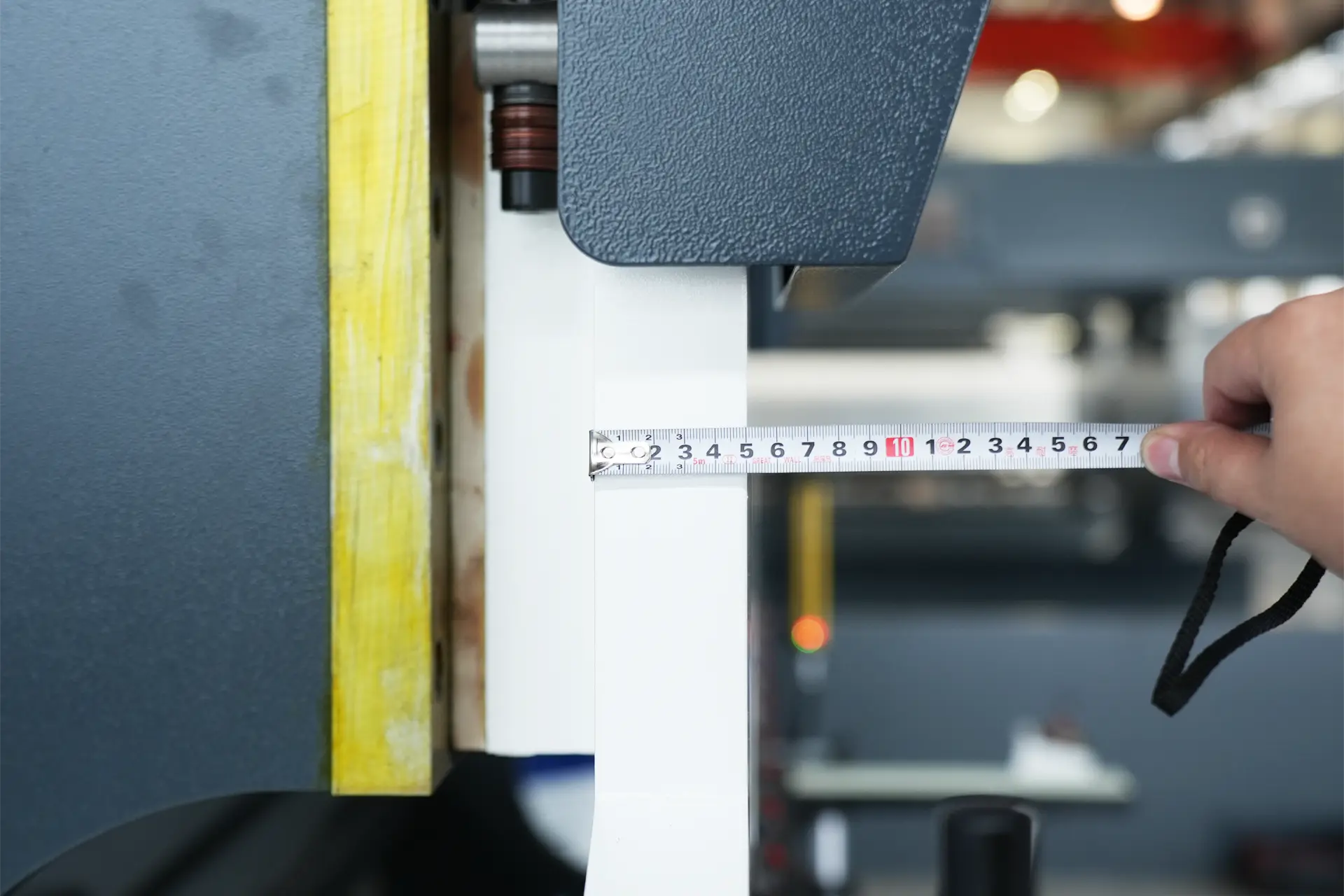

Thickness of workbench (70mm)

Thickness of side panel (45mm)

Thickness of slider (50mm)

Warranty

30-DAY MONEY BACK GUARANTEE

You should feel completely satisfied with your KRRASS Press Brake purchase, and your peace of mind is a significant part of that process. We want you to feel the same confidence in your new KRRASS machine that we do, which is why every Press Brake purchase includes our Hassle-Free KRRASS 30-Day Return option in order to fully experience and evaluate their new KRRASS machine. It allows you to return or exchange your KRRASS purchase, for any reason, within 30 days of initial purchase. Refunds are simple and are issued once the original machine and all accompanying accessories have been returned. The refund or exchange will be issued minus the 15% restocking fee for items & accessories, 25% KRRASS Press Brake Machine Series customization fee, and shipping or handling costs are not included. Click here for details

2-YEAR LIMITED MACHINE WARRANTY

2 years Bumper to Bumper machine warranty for all machine mechanical and electrical components. (Except consumables parts) The Company represents and warrants that the KRRASS All Series of products will perform according to the warranty policy stated above from date of invoice. Products will be free from defects in materials and workmanship under normal use and service for the stated period. KRRASS has the responsibility to offer a timely solution and/or repair if deemed inoperable or defective by KRRASS Repair & Support Specialists. Clients are obligated to show proof of any such claims of machine parts or operational defects. Click here for details

Reviewed by 10 users

Related products

Related products

-

Sale!

Sale!

WC67K-300T3200 Sheet Metal Press Brake Machine with E21 Control and Manual Crowning

5.00 out of 5$33,099.00Original price was: $33,099.00.$30,899.00Current price is: $30,899.00. Add to cart -

Sale!

Sale!

WC67K-160T3200 Press Brake Machine with Estun E300P Control and Manual Crowning

5.00 out of 5$21,299.00Original price was: $21,299.00.$19,699.00Current price is: $19,699.00. Add to cart -

Sale!

Sale!

WC67K-80T2500 NC Press Brake with E21 Control,Sheet Metal Hydraulic Press Brake

5.00 out of 5$13,160.00Original price was: $13,160.00.$11,160.00Current price is: $11,160.00. Add to cart -

Sale!

Sale!

WC67K-125T2500 Hydraulic Press Brake with E21 Control

5.00 out of 5$14,950.00Original price was: $14,950.00.$12,850.00Current price is: $12,850.00. Add to cart

Leave feedback about this