Discover what influences metal laser cutting machine price in our detailed buyer's guide, ideal for businesses seeking cost-effective solutions.

Today metal laser cutters are not limited to large industrial complexes, and many small to medium-sized businesses have adopted these machines into their workflow. Their versatility and ease of use have allowed them to gain widespread adoption.

How much does a laser cutter cost, and what type of machine best suits your production needs? This article explains the costs associated with laser cutters and gives a detailed price breakdown from small businesses to large industrial operations.

Definition of Metal Laser Cutting Machine

A metal laser cutting machine is a high-precision tool that uses a laser beam to cut through various types of metal sheets and plates. The machine works by focusing a high-powered laser onto the metal surface, which melts or vaporizes the material, allowing it to be cut with remarkable accuracy. These machines are commonly used in manufacturing, fabrication, and industrial applications for cutting metals like steel, aluminum, stainless steel, and more.

Metal laser cutting machines are crucial for their high precision and accuracy, enabling intricate designs and tight tolerances essential in various industries like automotive and aerospace. Their versatility allows them to cut a range of metals and thicknesses efficiently, producing clean, smooth edges with minimal material waste. This reduces production costs and the need for additional finishing.

Additionally, these machines enhance productivity with their speed and automation capabilities, integrating seamlessly into automated production lines. The non-contact cutting process minimizes tool wear and maintenance, while the ability to create complex shapes expands design possibilities. Overall, metal laser cutting machines are vital for high-quality, efficient, and adaptable metal fabrication.

3 Main Metal Cutting Process

Laser Generation and Beam Focusing

The metal cutting process begins with the generation of a laser beam, which is created by a laser source such as a CO2 or fiber laser. This laser beam is then amplified and directed through a series of mirrors and lenses to focus it into a highly concentrated point. The focused beam, possessing extremely high energy density, is aimed at the metal surface through a nozzle. This intense concentration of light ensures that the laser can effectively heat the metal to its melting or vaporization point, enabling precise and efficient cutting.

Cutting and Assist Gas Application

When the focused laser beam makes contact with the metal, it heats the material rapidly, causing it to melt or vaporize. The process is facilitated by an assist gas, which is blown through the nozzle along with the laser beam. The assist gas serves multiple purposes: it removes the molten metal and debris from the cutting area, preventing blockages and improving the cut quality, and it can also reduce oxidation by creating a clean cutting environment. The choice of assist gas—such as oxygen, nitrogen, or compressed air—depends on the type of metal and the desired finish.

Control Systems and Finishing

The movement and positioning of the laser beam are controlled by a sophisticated computer system that directs the cutting head or the material according to the programmed design. This precision allows for the creation of complex shapes and detailed patterns with high accuracy. After the cutting process, the metal is allowed to cool, either naturally or with the aid of cooling systems. The laser cutting technique produces clean and smooth edges, typically reducing the need for additional finishing or post-processing. This results in a high-quality, precise cut that enhances the overall efficiency and effectiveness of the metal fabrication process.

Types of Metal Laser Cutting Machines

Laser-cutting machines come in several varieties based on size, power, application, and cost. However, the biggest differentiating factor between laser cutting machines is the type of laser used for the cutting process. There are 4 major types of lasers used in modern metal laser cutting machines.

CO2 Laser Cutting Machines

CO2 (Carbon Dioxide) laser cutting machines consist of a glass tube filled with a gas mixture. A high-voltage current flows through the glass tube, exciting the gas molecules. The excited molecules radiate low-energy photons, amplified by reflectors at the edge of a glass tube. Photons repeatedly bounce across the reflectors until a powerful laser beam is formed.

The gas mixture of the CO2 laser cutter consists of several elements, including helium, hydrogen, carbon dioxide, nitrogen, oxygen, and xenon, with CO2 making up the bulk of the gas mixture.

ND: YAG Laser Cutting Machines

ND: YAG stands for neodymium-doped yttrium aluminum garnet. It is a complex crystal specially designed to act as a laser medium. The neodymium crystal is excited by an external source, usually a high-wattage lamp. Then similar to CO2 lasers, it is amplified using surrounding reflectors until a desired intensity is achieved.

The power output of an Nd: YAG laser cutter is primarily determined by the size of the neodymium crystal rod used as the gain medium. ND: YAG lasers are less common in industrial cutting operations and are primarily limited to skin care work.

Fiber Laser Cutting Machines

A fiber laser cutting machine is an industrial laser cutting equipment that uses a high-powered fiber laser to cut through various materials with high precision and accuracy. Fiber cutting machines suit thin, mild, and thick metal sheets and tubes. They are specifically good for cutting stainless steel and non-ferrous materials. With 500W plus laser power, they can cut through very thick materials.

Diode Laser Cutting Machines

Diode lasers are solid-state lasers using semiconductor material as a laser gain medium. They work and operate similarly to fiber and neodymium options and share many design elements.

A typical diode laser cutter is much smaller and often used by hobbyists for marking, engraving, and occasionally cutting soft materials like plywood and acrylics. Such laser cutters are not intended for heavy use and typically use cheaper optical lenses, resulting in lower cutting precision.

Which Laser Cutting Machine Is Best for Metals

The biggest deciding factor is material compatibility. You should choose a laser-cutting machine based on your specific material-cutting needs. Not all laser cutting systems support plastic or wood cutting, but they are still nice to have features.

CO2 laser cutter systems are designed to cut metal and non-metal options and are only incompatible with reflective metal surfaces like brass or copper. Neodymium laser cutters work best on metals and are compatible with some non-metal materials like ceramics and glass.

Solid-state laser cutters like neodymium and fiber laser machines are considerably more energy efficient, typically ranging between 20% to 35%. If you’re worried about the power consumption costs of your laser cutting machines, it is strongly recommended that you pick an energy-efficient model.

Shockingly diode-based laser cutter systems are the most efficient going all the way up to 65% energy efficiency for 12-15W lasers. However, it should be noted that these systems are typically sold as laser engravers with minor cutting capabilities.

It is important to note that even the best diode laser cutter on the market is not designed to cut sheet metal. You may be able to force it to cut through very thin sheets of metal (under 0.04 in.) at a slow cutting speed, but even then, the results would be disappointing.

Use the detailed comparison table below to narrow down the most suitable laser metal cutter option for your needs.

| Laser Technology | CO2 | Fiber | Nd: YAG | Diode |

| Energy Efficiency | Lowest | Medium | Medium | Highest |

| Pricing | Low | High | High | Very Low |

| Life Span | Short | Very Long | Long | Medium |

| Precision | Low | Very High | High | Medium |

| Power Output | Medium to High | Very High | Medium | Very Low |

| Material Compatibility | Metals & Non-Metals | Mostly Metals | Mostly Metals | Non-Metals |

| Versatility | Medium | High | Low | Low |

| Applications | Metal Cutting, Metal Engraving, Non-Metal Cutting | Metal Cutting, Metal Engraving, Non-Metal Engraving, Metal Marking, Metal Cleaning | Metal Cutting, Ceramic Cutting, Medical Use | Wood Cutting, Wood Engraving, Thin Material Cutt |

Metal Laser Cutting Machine Average Price

A metal laser cutter can cost as little as a few hundred dollars for small hobbyist machines and go upwards of a million for industrial-grade laser machines. However, their automation and multi-axis motion are huge cost contributors for those extremely expensive machines.

All prices listed below are in USD and are subject to change after publishing this article. But overall, these numbers should give customers all the necessary information for making a good purchasing decision.

- The cheapest laser cutter is a diode-based machine at <$500. Don’t be taken in by the attractive pricing. These models are designed for plywood engraving and cutting and not for metalwork industries.

- Going up, you can find a beginner-friendly hobbyist CO2 metal laser cutter between $2,000-3,000.

- Entry-level fiber metal laser cutting machines cost $15,000. These machines are equipped with a low-power laser and will struggle when cutting metal plates (>6mm).

- At $30K-100K you are slowly moving toward professional factory equipment. A CO2-powered laser cutter, generally speaking, will be under $50k. While a fiber laser cutting machine costs upwards of that $50K mark.

- Going above $200K, you will find specialized fiber laser machines for large-scale productions or robotic arm-assisted fiber lasers for detailed custom production.

CO2 VS. Fiber Lasers

Knowing to choose whether CO2 or fiber laser technology is important. Fiber lasers are a newer technology with several key benefits, like the compact size and higher precision. A standard $15-20k Fiber laser will have a lifespan of over 30,000 hours. Contrarily a $2,500 CO2 model will only last around 2,000 hours before you need to change the laser tube.

For small business owners looking for an affordable laser cutter, a CO2-powered machine would be a decent option.

Small Machine VS. Industrial Options

A smaller metal laser cutting machine (<$50K) is designed to run occasionally for no more than a few hours a day. Such laser machines typically last a couple of years before serious maintenance is required.

Industrial laser machines (>$100K) are meant for large factories that run the machines all day without a break. The increased cost here is mostly due to the better reliability and construction of the machine that enables its extensive use.

Customized Pricing Options

All major brands offer custom quotes for their laser-cutting machines. The price for these machines will vary based on the number of units, shipping location, and additional parts requested by the buyer. You will be able to get a significant discount based on your needs.

Factors that Affect the Metal Laser Cutting Machine

1. Type of Laser

The importance of a good laser source in your metal laser cutter should not be underestimated. A fiber laser cutting machine is approximately ten times more expensive than a CO2 one. But it is also more energy efficient and has a higher laser power configuration in a smaller size.

2. Power Output of Laser

As you increase the power output (wattage), Lasers become increasingly difficult to manufacture. Hence, you will see an exponential increase in price as you move from low-power laser cutters to higher ones.

Laser engravers start at the lower power option, around 1-5W. For sheet metal fabrication, you need at least 50W, irrespective of the laser source. You will need to move to kilowatt lasers to cut different materials like thick stainless steel.

3. The precision of Laser

The precision of a laser is measured as spot diameter. A smaller laser spot will lead to precise cuts and higher cutting speeds. CO2 lasers have a spot diameter between 0.01 in. (~250 microns), while fiber lasers can go as low as 0.001 in. (~25 microns). Higher precision lasers require robust and expensive optical components.

4. Machine Size

Like all machines, larger ones are more expensive. The size of their work bed limits all laser cutters. You can process large metal sheets and cut more parts with larger beds. Another big cost contributor for larger machines is their shipping costs due to the increased size and weight.

5. After Sale Services

Once you buy a complex machine like a laser cutter, you can run into various operational issues. Your machine could be damaged in shipping or have a defective servo motor. You need a trustworthy and reliable after-sales service to help you get your machine up and running during those critical moments.

It is important to buy from a reputable seller willing to help you even after making a sale. After-sales services can include some of the following options.

- Customer Support for Initial Machine Setup

- Machine Operator Training

- Diagnostic Help

- Sale of Replacement Parts

- etc.

Most manufacturers offer after-sales services for free. However, some might charge you extra.

If Worth Investing A New Laser Cutter Machine

The good laser metal cutting machine price can seem a lot at first glance. And many of you might opt for a metal-cutting service provider instead of buying your own machine.

Although metal cutting services can be a viable option for some, most people should consider buying their own metal laser cutter as it offers significant benefits for their business.

Following are a few key benefits that owners of laser cutting machines enjoy.

- Flexibility

- Versatility

- Lower Production Costs

- Reliability

Having a laser cutter on hand will help run the production process more smoothly. You know the number of laser-cut parts that can be produced daily. And you don’t have to wait for someone else to start production. Additionally, the cost per part is significantly lower than metal cutting services.

Options like a fiber laser machine are small and compact enough to fit easily in your workshop. And the machine cost is low enough that you can get a return on your investment within a year.

Top 10 Metal Laser Cutting Machine Brands

| Brand | Overview | Key Products | Strengths |

|---|---|---|---|

| Trumpf | German manufacturer specializing in industrial machine tools and lasers. | TruLaser series | High precision, innovative technology, robust build quality. |

| Bystronic | Swiss company known for high-performance cutting solutions. | ByStar Fiber, BySmart Fiber | Advanced automation, user-friendly software, energy-efficient designs. |

| Amada | Japanese manufacturer offering comprehensive metalworking solutions. | ENSIS, LCG, FOL series | Versatility, high cutting speeds, excellent support network. |

| Mazak | Global leader in machine tools, including laser cutting technology. | OPTIPLEX series | Cutting-edge technology, high productivity, reliable performance. |

| Han's Laser | Chinese company known for innovative laser solutions. | G3015F, P-Series | Competitive pricing, strong R&D, extensive product range. |

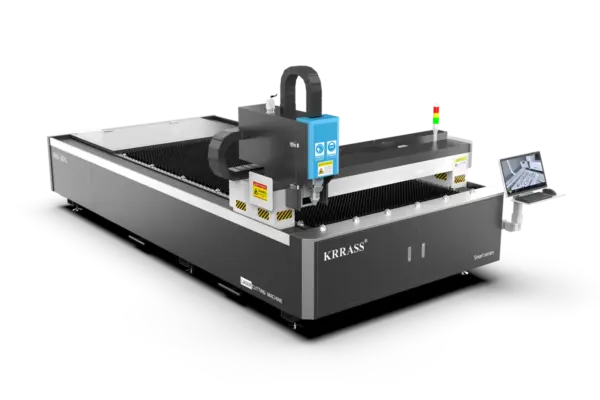

| KRRASS | Renowned Chinese manufacturer specializing in metal forming and cutting machines. | Smart series, MB series | Advanced features, robust construction, excellent customer service. |

| Cincinnati | US-based company with a strong reputation in manufacturing cutting solutions. | CL-960, CL-940 | High power, exceptional accuracy, durable designs. |

| Prima Power | Italian manufacturer known for flexible manufacturing systems. | Platino Fiber, Laser Next | Customizable solutions, high-speed cutting, eco-friendly technology. |

| Salvagnini | Specializes in automation and flexible manufacturing systems. | L5, L3 series | High efficiency, automation integration, innovative features. |

| LVD | Belgian manufacturer offering a wide range of laser cutting machines. | Phoenix FL, Electra FL | Precision cutting, user-friendly interfaces, robust performance. |

Metal Laser Cutting Machine Price: How to Get Best Deal

Here are four tips that will help you finalize your purchase.

Choose an Appropriate Machine Size

Laser cutters always need a little extra room in your workshop for peak operation. You need enough room for decent airflow so that the laser system won’t overheat and space for machine accessories. Choose a machine size that fits your workspace and leaves plenty of room to walk around.

Consider Future Operational Costs

Laser cutters can be expensive to run, and small costs will start to add up. The two biggest cost factors are power consumption which leads to excessive energy bills, and maintenance, like replacing the laser tube of a gas laser cutter.

Account for Shipping Costs in Your Budget

Shipping costs can often be greater than the price of the laser cutter. Large and heavy machines cost a lot to ship around the world. This can be mitigated by buying a modest-sized machine from a company with an established global shipping network.

Production Capacity

Production capacity is controlled by the laser’s cutting speed and the machine’s bed size. Cutting speed further decreases when dealing with a thicker piece of metal. Consider your production needs before deciding on a machine.

Post Processing Time

Lasers can generate a lot of heat, especially when cutting thick materials at low speeds. This can cause melted metal beads to form at the edges of the work.

Final Thought

Laser cutters are versatile machines for processing both metal and non-metal materials and are available at a range of prices. However, additional features and advanced performance capabilities can increase the cost. Your ideal production capacity, material choice, and power requirements will significantly influence the final price of your laser cutter. For detailed information, you can often contact sellers directly.

For example, KRRASS offers a range of laser cutters with customizable features to match your specific production needs, ensuring high performance and reliability.

Feel free to reach out to KRRASS for tailored solutions and quotes.