Введение

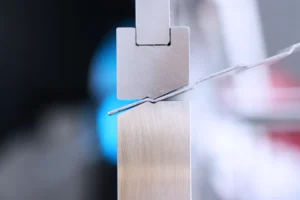

Press brakes are an essential tool in the manufacturing process. They are used to bend and shape metal into the desired shape and size. Press brakes are used in a variety of industries, including automotive, aerospace, and medical. They are used to create parts for cars, airplanes, and medical equipment. Press brakes are also used to create custom parts for specific applications.

Press brakes are a cost-effective way to streamline the manufacturing process. They are easy to use and can be used to create complex shapes and sizes. They are also highly accurate and can be used to create parts with tight tolerances. Нажимные тормоза are also versatile and can be used to create parts from a variety of materials, including aluminum, steel, and stainless steel.

Press brakes are a cost-effective way to streamline the manufacturing process. They are easy to use and can be used to create complex shapes and sizes. They are also highly accurate and can be used to create parts with tight tolerances. Нажимные тормоза are also versatile and can be used to create parts from a variety of materials, including aluminum, steel, and stainless steel.

Press brakes are an essential tool for any manufacturing process. They can help streamline the process and reduce costs. In this article, we will discuss how a press brake can help streamline your manufacturing process.

How a Press Brake Can Help Streamline Your Manufacturing Process

1. Increased Efficiency

Press brakes are highly efficient machines. They can be used to create parts quickly and accurately. This can help reduce the amount of time it takes to complete a project. It can also help reduce the amount of labor required to complete a project. This can help reduce costs and increase profits.

2. Improved Quality

Press brakes are highly accurate machines. They can be used to create parts with tight tolerances. This can help improve the quality of the parts being produced. It can also help reduce the amount of scrap and rework that is required. This can help reduce costs and improve customer satisfaction.

3. Reduced Costs

Press brakes are cost-effective machines. They can be used to create parts quickly and accurately. This can help reduce the amount of labor required to complete a project. It can also help reduce the amount of scrap and rework that is required. This can help reduce costs and improve profits.

4. Versatility

Press brakes are versatile machines. They can be used to create parts from a variety of materials, including aluminum, steel, and stainless steel. This can help reduce the amount of time it takes to complete a project. It can also help reduce the amount of labor required to complete a project. This can help reduce costs and improve profits.

Заключение

Press brakes are an essential tool for any manufacturing process. They can help streamline the process and reduce costs. They are highly efficient, accurate, and versatile machines. They can be used to create parts quickly and accurately. This can help reduce the amount of time it takes to complete a project. It can also help reduce the amount of labor required to complete a project. This can help reduce costs and improve profits.

Часто задаваемые вопросы

Q: What is a press brake?

А: A press brake is a machine used to bend and shape metal into the desired shape and size. It is used in a variety of industries, including automotive, aerospace, and medical.

Q: How does a press brake help streamline the manufacturing process?

А: A листогибочный пресс can help streamline the manufacturing process by increasing efficiency, improving quality, reducing costs, and providing versatility. It can be used to create parts quickly and accurately, which can help reduce the amount of time it takes to complete a project. It can also help reduce the amount of labor required to complete a project. This can help reduce costs and improve profits.

Q: What materials can a press brake be used to create parts from?

А: A press brake can be used to create parts from a variety of materials, including aluminum, steel, and stainless steel.

KRRASS: лучший выбор для

все производители обработки листового металла

При рассмотрении общих затрат на приобретение, обслуживание и эксплуатацию оборудования для обработки листового металла, лучшим выбором станет услуга по изготовлению изделий из листового металла от бренда KRRASS. KRRASS имеет превосходную репутацию на рынке благодаря своей ориентации на стабильность и качество по самым конкурентоспособным ценам. Будь то листогибочный пресс или любое другое оборудование, наша команда экспертов обладает необходимым сочетанием отраслевых знаний и новейших инструментов, чтобы предоставить вам лучшие продукты и услуги на рынке. Более того, мы отличаемся нашей передовой системой, которая полностью работает в онлайн-режиме. Просто сообщите нам о ваших потребностях в продукции, запросите ценовое предложение и начните процесс.

Отправьте запрос и начните прямо сегодня!

Получите мгновенную цену

Чтобы узнать больше о наших продуктах, посетите наш сайт и подпишитесь на нашу рассылку. YouTube-канал