This article delves into the intricacies of Sheet metal laser cutting, exploring its processes, types, advantages, and how to choose the right service. Whether you're a professional in the industry or just curious about this cutting-edge technology, our insights will illuminate the art and science of laser cutting in the modern manufacturing landscape.

- What Is Sheet Metal Laser Cutting?

- Sheet Metal Laser Cutting Process

- Types Of Laser Machines To Use In Sheet Metal Laser Cutting

- Types Of Laser Used In Cutting Sheet Metal

- Advantages Of Laser Cutting Sheet Metal

- Disadvantages Of Laser Cutting Sheet Metal

- How To Reduce Sheet Metal Wastage During Laser Cutting

- Sheet Metal Laser Cutting Tolerances

- How To Ensure Quality During Sheet Metal Laser Cutting

- How To Choose Good Laser Cutting Service

- Conclusion

1.What Is Sheet Metal Laser Cutting?

Have you ever marveled at the intricate designs and precise cuts found in metalwork? The secret behind these masterpieces is often sheet metal laser cutting, a state-of-the-art technology revolutionizing the manufacturing industry. So, what exactly is it?

In layman's terms, sheet metal laser cutting is a process where a high-powered laser beam is used to cut, engrave, or shape metal sheets. This method stands out for its precision, speed, and flexibility, making it a go-to choice for various industries, including automotive, aerospace, and electronics.

But it's not just about cutting metal. The beauty of this technology lies in its ability to produce complex shapes and designs that traditional cutting methods can't achieve. With computer-aided design (CAD) software, the laser cutter can follow intricate patterns, making it perfect for custom and detailed projects.

Moreover, the process is incredibly efficient. Since it's computer-controlled, the risk of human error is minimized, leading to consistent, high-quality results. Plus, the laser's precision means less waste material, making it a more sustainable choice in the long run.

2.Sheet Metal Laser Cutting Process

Diving deeper into the world of manufacturing, let's explore the intriguing process behind sheet metal laser cutting. This process isn't just about turning on a machine and cutting metal; it's an intricate dance of technology, precision, and expertise.

It all starts with design. Before a single laser beam is fired, engineers and designers collaborate to create detailed digital models using CAD software. This step is crucial as it determines the exact dimensions and patterns the laser cutter will follow.

Next comes the setup. The sheet metal, which can range from steel to aluminum, is carefully placed on the cutting table. Here, precision is key. Even a slight misalignment can lead to errors, so this step is meticulously executed.

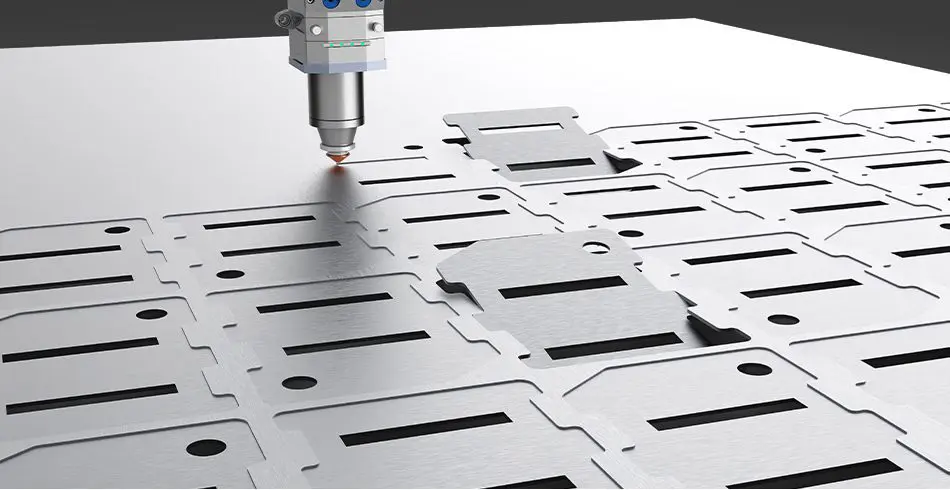

Then, the heart of the process: the laser cutting itself. The machine's laser beam, focused and intensified through a series of lenses, melts, burns, or vaporizes the metal along the predetermined path. The precision of this process allows for complex shapes and clean cuts with smooth edges, something traditional cutting methods struggle to achieve.

But it's not over yet. After cutting, the metal often undergoes further processing. This might include bending, welding, or assembling into the final product. Throughout, quality control measures ensure that each piece meets the stringent standards required.

3.Types Of Laser Machines To Use In Sheet Metal Laser Cutting

The art of sheet metal laser cutting is not a one-size-fits-all approach. Various types of laser cutting machines are utilized, each with its unique features and advantages. Let's delve into some of the most common types.

3.1 Flying Optic Laser Cutting Machine

The Flying Optic Laser Cutting Machine is all about speed and precision. In this system, the laser remains stationary while the cutting bed moves the material around. This allows for rapid cutting speeds and the ability to quickly change directions, making it ideal for complex patterns and high-volume projects.

3.2 Moving Material Laser Cutting Machine

In contrast, the Moving Material Laser Cutting Machine involves moving the material under a stationary laser beam. This method is particularly effective for cutting thicker materials, offering greater control over the laser's intensity and heat output, leading to precise and clean cuts.

3.3 Punch Laser Cutting Machine

Combining laser cutting with traditional punching, the Punch Laser Cutting Machine is a hybrid that offers versatility. It's capable of not only cutting but also forming and creating three-dimensional shapes. This machine is perfect for intricate designs and materials that require additional processing beyond cutting.

3.4 Pulsed Laser Cutting Machine

The Pulsed Laser Cutting Machine operates in short bursts, delivering high energy in pulses. This method is ideal for materials sensitive to heat, as it minimizes the heat-affected zone, reducing thermal damage. It’s particularly useful for fine, detailed work on thinner or more delicate materials.

4.Types Of Laser Used In Cutting Sheet Metal

In the realm of sheet metal laser cutting, not all lasers are created equal. Different types of lasers are employed based on their unique properties and the specific requirements of the cutting task. Let's shine a light on the main types of lasers used in this field.

CO2 Lasers

CO2 lasers are among the most commonly used in sheet metal cutting. These lasers are highly efficient and suitable for cutting, engraving, and boring a wide range of materials, including non-metallics. They are particularly known for their smooth cutting edges in thicker materials.

Fiber Lasers

Fiber lasers represent a more modern technology in laser cutting. They use a solid-state laser made from a 'seed laser' and amplified through special fibers. This type results in extremely precise cuts and is energy-efficient, making it ideal for cutting reflective metals like aluminum and copper.

Nd:YAG Lasers

Nd:YAG (Neodymium-Doped Yttrium Aluminum Garnet) lasers are versatile and can be used for both engraving and cutting. They are particularly effective for cutting thicker materials and are known for their high energy and ability to cut through materials that CO2 lasers might struggle with.

Crystal Lasers

Crystal lasers, such as Nd:YVO4 or Yb:YAG, provide high-intensity beams and are used for extremely precise cutting applications. They are excellent for cutting thin to medium-thick metals and have a relatively long lifespan, although they can be more expensive in terms of maintenance and operation.

5.Advantages Of Laser Cutting Sheet Metal

The innovation of laser cutting in the field of sheet metal fabrication isn't just a matter of modernity; it brings with it a plethora of advantages that revolutionize how we approach metalworking. Let’s explore the key benefits that make laser cutting a preferred method in the industry.

Precision and Accuracy

One of the most significant benefits of laser cutting is its incredible precision. The ability to make finely detailed cuts and intricate patterns with minimal errors is unparalleled. This accuracy is particularly crucial in industries where even the smallest miscalculation can have significant consequences.

Versatility

Laser cutting machines are versatile tools capable of handling various types and thicknesses of metal. They can easily switch between different projects and materials, making them an invaluable asset in workshops that work with a diverse range of products.

Speed and Efficiency

In today’s fast-paced manufacturing world, time is of the essence. Laser cutting stands out for its speed, capable of completing tasks much faster than traditional methods. This efficiency not only speeds up production but also reduces labor costs and increases throughput.

High Quality and Reduced Material Waste

The precision of laser cutting not only ensures high-quality output but also significantly reduces material waste. This is particularly important in an era where material efficiency and sustainability are becoming increasingly crucial.

Flexibility in Design

The flexibility to execute complex designs without the need for multiple tools or setups is another advantage. This allows for creative freedom in design, making it possible to bring even the most intricate ideas to life.

Safety and Cleanliness

Laser cutting is a relatively safer process, as it minimizes the physical contact between the machine and the material, reducing the risk of accidents. Additionally, it produces less debris and dust, contributing to a cleaner and healthier work environment.

6.Disadvantages Of Laser Cutting Sheet Metal

While laser cutting is a highly efficient and precise method for working with sheet metal, it's essential to acknowledge that, like any technology, it comes with certain limitations. Understanding these disadvantages helps in making informed decisions when choosing the right cutting method for your project.

High Initial Investment

One of the primary drawbacks of laser cutting technology is the high initial investment. Laser cutting machines and their maintenance can be quite costly, making them a significant investment for any manufacturing facility.

Limitations on Material Thickness

Despite their precision, laser cutters have limitations when it comes to the thickness of the material they can handle. Thicker materials can be challenging to cut through and may not yield the desired precision or quality of cut.

Energy Consumption

Laser cutting machines require a significant amount of energy to operate, especially for more powerful lasers. This high energy consumption can lead to higher operational costs over time.

Heat Affected Zone (HAZ)

The process of laser cutting generates a significant amount of heat, which can affect the material around the cut, known as the Heat Affected Zone (HAZ). This can alter the material's properties and may require additional processing to rectify.

Limitations in Cutting Certain Materials

Not all materials are suitable for laser cutting. Certain materials, like plastics and foams, can emit hazardous gases when cut with a laser. This necessitates careful consideration of the materials used and appropriate safety measures.

7.How To Reduce Sheet Metal Wastage During Laser Cutting

Minimizing waste in sheet metal laser cutting is not only beneficial for cost-efficiency but also crucial for environmental sustainability. Implementing strategies to reduce wastage can significantly impact the overall effectiveness and eco-friendliness of the cutting process.

Optimize Nesting Techniques

Utilizing advanced nesting software is key to optimizing material usage. By strategically arranging the patterns to be cut, this software minimizes the unused spaces between parts, effectively reducing material waste.

Regular Maintenance of Equipment

Regular maintenance of laser cutting equipment ensures that the machinery operates at peak efficiency. A well-maintained machine produces more accurate cuts, reducing the chances of material wastage due to errors.

Use of High-Quality Materials

Employing high-quality materials can decrease waste. Better quality materials often have fewer imperfections, which means less material is discarded during the cutting process.

Implement Lean Manufacturing Principles

Adopting lean manufacturing principles can help in identifying and eliminating waste. This involves continuous process improvement and focusing on value-added activities.

Train Personnel in Efficient Operation

Skilled operators who are well-trained in the nuances of laser cutting can make a significant difference in reducing waste. Their expertise allows for more efficient use of materials and minimizes errors that can lead to wastage.

8.Sheet Metal Laser Cutting Tolerances

When delving into sheet metal laser cutting, understanding tolerances – the allowable limits of variation in dimensions – is crucial. Tolerances are fundamental in ensuring the final product meets the required specifications and fits perfectly in its intended application.

Understanding Tolerance Levels

Tolerance levels in laser cutting can vary based on several factors, including the type of laser, the thickness and type of material, and the cutting process's complexity. Generally, laser cutting can achieve very tight tolerances, often within a few thousandths of an inch.

Factors Affecting Tolerances

Various factors impact the tolerances achievable in laser cutting. These include the laser's focus, the condition of the cutting equipment, the material's thermal properties, and the stability of the work environment. Each of these elements needs to be controlled for optimal precision.

Importance in Custom Fabrication

In custom fabrication, adhering to specific tolerances is vital. Precision is not just about achieving the right size; it's also about ensuring the integrity and functionality of the final product, especially in industries where precision is non-negotiable, such as aerospace and medical devices.

Balancing Precision and Practicality

While striving for tight tolerances is important, it's also necessary to balance precision with practicality. Over-specifying tolerances can lead to unnecessary costs and production delays. Understanding the application's requirements and the material's capabilities is key to achieving this balance.

9.How To Ensure Quality During Sheet Metal Laser Cutting

Maintaining high quality in sheet metal laser cutting is essential for achieving the desired outcomes and satisfying customer expectations. There are several key practices and considerations that can help in ensuring the quality of the laser cutting process.

Regular Maintenance and Calibration of Equipment

Regular maintenance and calibration of laser cutting equipment are fundamental to ensure consistent quality. This includes checking the alignment of the laser, ensuring the cutting head is in good condition, and calibrating the machine for precise operation.

Use of High-Quality Materials

The quality of materials used in laser cutting significantly affects the final product. Using high-grade metals ensures fewer imperfections and consistent results, leading to a higher quality finish.

Skilled and Trained Operators

The skill and expertise of operators play a crucial role in the laser cutting process. Trained professionals can effectively manage the subtleties of the process, from adjusting machine settings to handling materials, which contributes to the overall quality.

Implementing Quality Control Measures

Quality control is vital at every stage of the laser cutting process. This includes pre-cutting inspections, in-process monitoring, and post-cutting checks. Ensuring each piece meets the set standards is crucial for maintaining overall quality.

Adapting to Material Specifics

Different materials react differently under a laser. Understanding and adapting to these specifics, such as adjusting the laser's power, speed, and focus for different materials, is essential for achieving the best results and maintaining quality.

10.How To Choose a Good Laser Cutting Service

Selecting the right laser cutting service is a critical decision that can significantly affect the quality, efficiency, and cost-effectiveness of your projects. Here are some essential factors to consider when choosing a laser cutting service provider.

Experience and Expertise

Look for a service provider with substantial experience and expertise in laser cutting. Their track record and portfolio can give you insights into their capabilities and the types of projects they have successfully handled.

Quality of Equipment

The quality and modernity of the laser cutting equipment used by the service provider are crucial. Advanced machines can handle a broader range of materials and offer greater precision and efficiency.

Material Capabilities

Ensure that the service provider can work with the specific types of materials you require for your projects. Different materials require different laser settings and handling techniques.

Turnaround Time and Flexibility

Consider the provider's ability to meet deadlines. A service that can offer quick turnaround times without compromising on quality is vital, especially for time-sensitive projects.

Customer Service and Communication

Good communication and customer service are essential. The provider should be responsive, willing to discuss your specific needs, and offer solutions tailored to your project.

Cost-Effectiveness

While cost should not be the only determining factor, it's important to find a service that offers a good balance between quality and price. Requesting quotes from multiple providers can help you make an informed decision.

Conclusion

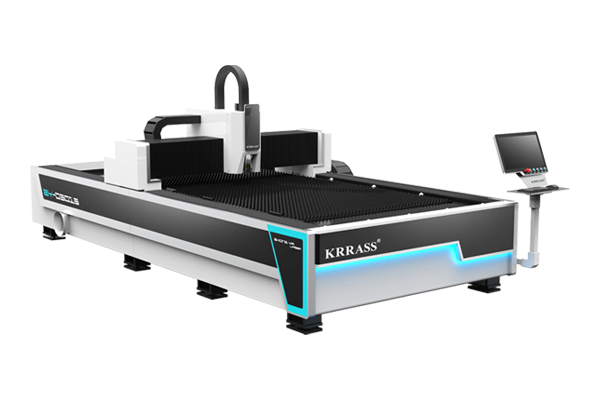

In conclusion, the world of Sheet Metal Laser Cutting is vast and full of potential. As we've explored its various facets, from the precise technologies to the effective strategies for quality and efficiency, it's clear that this method is pivotal in modern manufacturing. For those seeking the pinnacle of laser cutting technology, look no further than Krrass, China's leading manufacturer of Laser Cutting Machines. With state-of-the-art equipment and a commitment to excellence, Krrass is your go-to source for all your laser cutting needs.

Read More:

Exploring Ultra-Efficient Laser Cutting Technology

How Accurate is Laser Cutting Machine: Standard Laser Cutting Tolerances