Tube Fiber Laser Cutting Machines play a crucial role in modern manufacturing. They project a high-energy-density laser beam onto the workpiece surface. This concentrated energy instantly melts and vaporizes the irradiated area, while the CNC mechanical system precisely maneuvers the laser spot to execute highly accurate, rapid, and automated cutting.

Fiber laser cutting machines have revolutionized traditional machining by replacing mechanical knives with an invisible yet highly efficient laser beam. These machines offer a plethora of advantages, such as remarkable precision, swift cutting speed, unrestricted cutting patterns, automated layout capabilities, material savings, seamless cuts, and low processing costs. These merits have led to their extensive utilization across various industries like sheet metal fabrication, kitchenware production, electrical cabinet manufacturing, and automotive engineering.

1. Core Components of the Tube Fiber Laser Cutting Machine

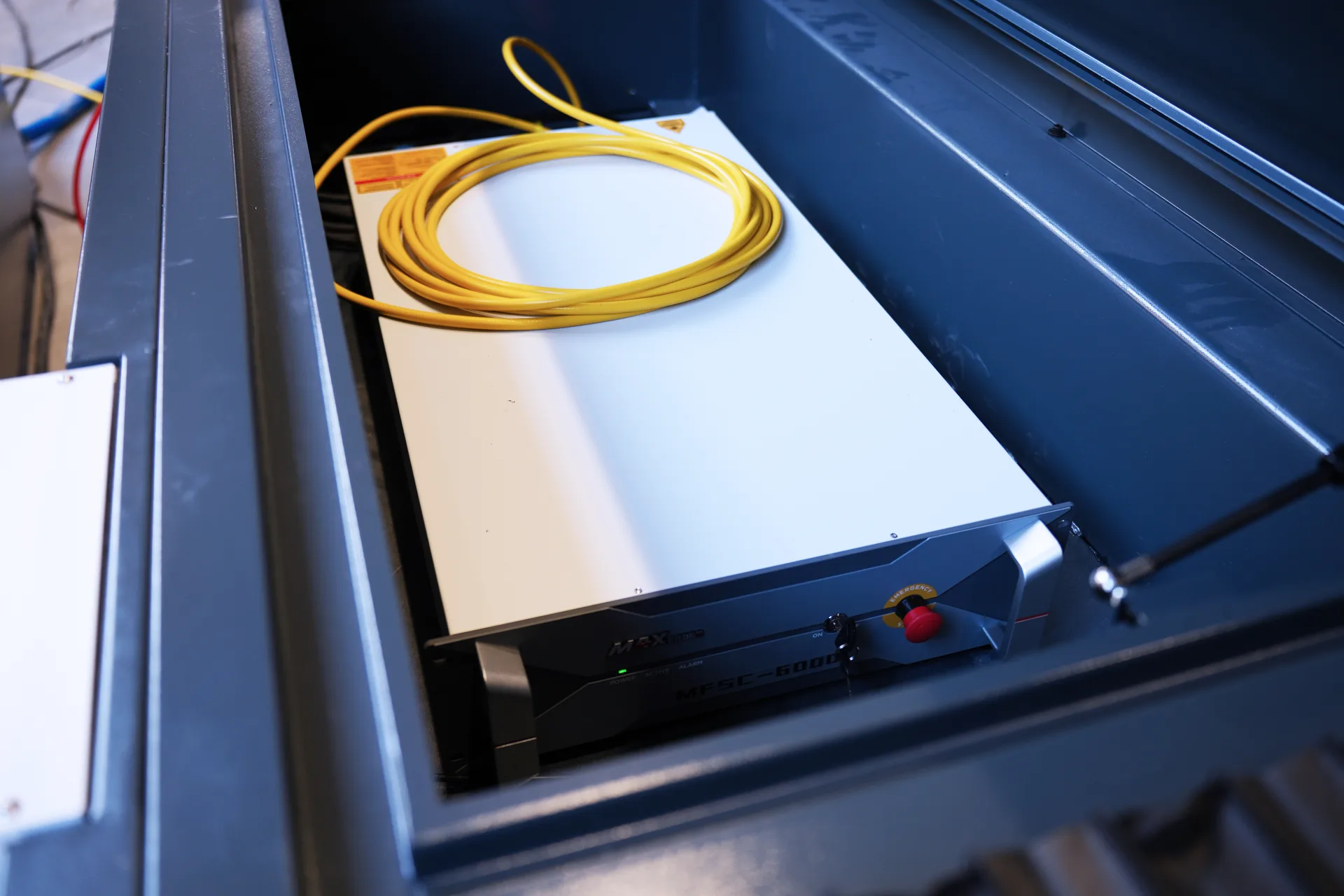

Fiber Laser Source

The fiber laser source is the heart of the fiber laser cutting machine, powering the entire cutting operation. Among different laser types, fiber lasers stand out with their higher efficiency, extended lifespan, minimal maintenance requirements, and lower overall costs. Renowned brands like Raycus and IPG are widely trusted for their top-notch laser sources.

Laser Cutting Head

The cutting head, a vital laser output device, comprises a nozzle, focus lens, and focus tracking system. It traverses along the preset cutting path, and its height demands meticulous adjustment based on varying materials, thicknesses, and cutting parameters. In low to mid-power machines, Raytools laser heads are commonly installed, while for high-power models ranging from 8KW to 12KW, the German Precitec laser heads are often preferred.

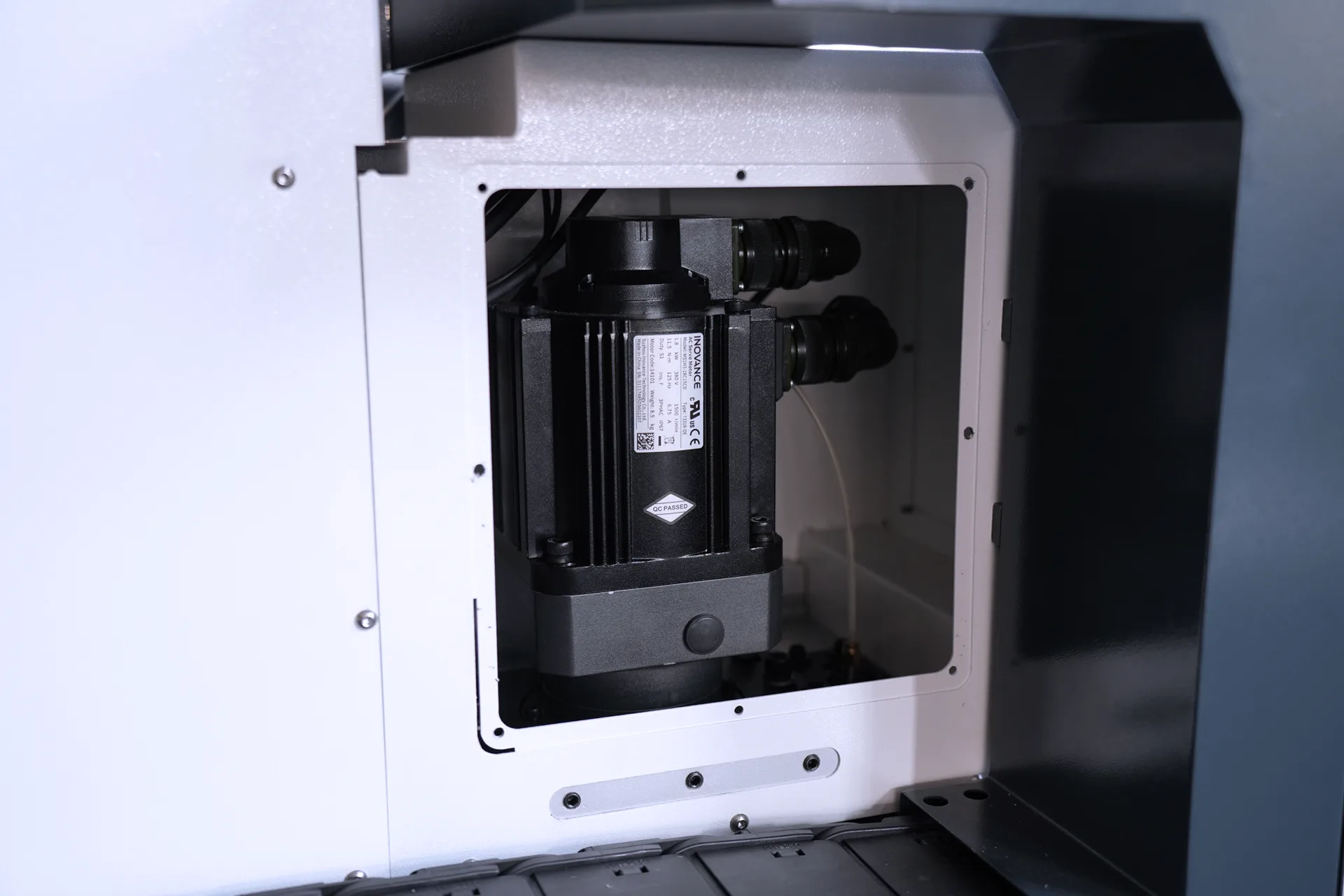

Servo Motors

Servo motors are the driving force behind the precise control of mechanical components in the servo system. They function as auxiliary motors with indirect speed variation capabilities. These motors ensure pinpoint accuracy in speed and position control by converting voltage signals into torque and rotational speed, thereby guaranteeing the cutting machine's high precision, rapid positioning, and repeatable positioning accuracy. Brands like Japan's Yaskawa are recognized for their reliable servo motors.

Water Chiller

The water chiller is essential for maintaining the optimal operating temperature of the laser source and cutting head. It features advanced functions such as input/output control switches, cooling water flow regulation, and high/low temperature alarms, ensuring stable performance. S&A is a popular choice among industrial water chillers.

Air Cutting System

The air cutting system encompasses an air compressor, filter devices, and an air dryer. It utilizes either bottled air or compressed air sources. Air cutting presents an economical alternative to other gas cutting methods, significantly reducing gas consumption costs compared to nitrogen.

Host

The host consists of the bed, beam, table, and Z-axis system. During the cutting process, the workpiece is placed on the bed, and the servo motor drives the beam to control the Z-axis movement. Users can customize parameters according to their specific needs.

Control System

The control system is the nerve center of the machine, orchestrating the movement of the X, Y, Z axes and precisely regulating the laser's output power.

Stabilizer

Connected between the laser, CNC machine tool, and power supply system, the stabilizer safeguards against external grid interference, ensuring uninterrupted operation.

2. Key Elements Influencing Performance

Laser Lens

Superior laser lenses are characterized by enhanced light reflection and reduced light loss, which directly contribute to improving the photoelectric conversion efficiency of the machine. There are two main categories: imported and domestic lenses. Domestic lenses can be further classified based on material origin, with significant differences in price, performance, and lifespan between them.

Operating Software

The operating software serves as the brain of the laser tube cutting machine, governing the laser generator and vibrating lens. It precisely controls the light output speed, power intensity, vibration speed, angle, and light direction of the lens. High-quality software is essential for maximizing the potential of the machine's components.

Laser Vibration Lens

The performance speed and accuracy of the laser tube cutting machine are highly dependent on the vibration lens. During operation, the lens generates heat, and prolonged use can lead to temperature elevation. A reliable vibration lens is crucial to maintain precision and prevent speed degradation.

Laser Generator

The laser generator is the core determinant of the machine's quality. Imported generators typically offer superior beam quality and higher electro-optical conversion rates. However, with the rapid development of the domestic laser industry, domestic generators have made significant strides. They can now meet the requirements of most industries, with a lifespan exceeding 3 - 4 years. Although imported generators may produce more refined results, they come with higher costs and more complex maintenance procedures, often involving overseas repairs and lengthy customs formalities. In contrast, domestic generators provide a cost-effective and convenient alternative.

Conclusion

In conclusion, when choosing a tube fibre laser cutting machine, it is advisable to opt for high-quality domestic laser lenses, stable and widely-used operating software, reliable laser vibration lenses, and a laser generator that suits your budget and requirements. By carefully considering these factors and understanding the key components of the machine, you can make an informed decision and select a laser cutting machine that will enhance your production efficiency and quality. KRRASS is dedicated to providing customers with high-quality and reliable equipment. For more detailed information, please visit our website.