Investing in a hydraulic metal brake machine can greatly boost the efficiency and precision of your metalworking operations. These machines play a crucial role in bending metal sheets with exceptional accuracy, consistency, and speed, making them indispensable across industries ranging from automotive to aerospace. Whether you are upgrading your current equipment or entering the realm of metal fabrication for the first time, grasping the nuances of hydraulic metal brakes is vital for making a well-informed purchasing decision.

Introduction

Hydraulic metal brake machines are sophisticated tools designed for bending metal sheets with precise control and efficiency. They utilize hydraulic pressure to exert force on a bending beam, enabling the shaping of various metals including steel, aluminum, and alloys.

These machines are essential in metalworking industries for their ability to produce bends with high accuracy and consistency, crucial for manufacturing components used in automotive, aerospace, construction, and other sectors. By leveraging hydraulic power, these brakes ensure not only the uniformity of bends but also the capability to handle a wide range of sheet thicknesses and complexities, making them indispensable in modern manufacturing processes.

What is Hydraulic Metal Brake

A hydraulic press brake is a specialized machine tool designed to bend and shape metal sheets and plates. By harnessing hydraulic power, it applies force to the workpiece positioned between a punch and a die, creating precise bends according to predetermined specifications. This technology is extensively utilized in manufacturing industries due to its high precision, efficiency, and capability to accommodate various metal thicknesses and complex bend configurations. Different models of press brakes can exert varying amounts of force, measured in tons, showcasing their versatility in fabricating metal components for construction, automotive, aerospace, and other industrial sectors.

Purpose of Using a Hydraulic Metal Brake

The primary purpose of using a hydraulic metal brake is to accurately bend and shape metal sheets and plates into desired forms. This capability is crucial for various industries that require precision and efficiency in metal fabrication. Here are the main reasons for using a hydraulic metal brake:

Precision Bending: Hydraulic metal brakes offer high precision in bending metal sheets, ensuring that the bends are accurate and consistent. This precision is essential for creating parts that meet exact specifications and fit correctly in assemblies.

Versatility in Material Thickness: Hydraulic metal brakes can handle a wide range of metal thicknesses, from thin sheets to thick plates. This versatility allows manufacturers to work with different materials without needing multiple machines.

Complex Bend Configurations: These machines are capable of producing complex bend configurations, which are often required in advanced manufacturing processes. This includes creating multiple bends in a single piece of metal or bending metal into intricate shapes.

Efficiency and Speed: Hydraulic metal brakes are efficient and can perform bending operations quickly. This speed is beneficial for high-volume production environments where time is a critical factor.

Consistency and Repeatability: Hydraulic systems provide consistent pressure and force, resulting in repeatable bends. This consistency is crucial for maintaining quality control in production.

Key Components of a Hydraulic Metal Brake

Hydraulic Cylinders

Hydraulic cylinders are the driving force behind the operation of a hydraulic metal brake. These cylinders use hydraulic fluid to create pressure, which is then converted into mechanical force. This force moves the bending beam to apply precise pressure on the metal sheet, enabling accurate bending.

The hydraulic cylinders provide the necessary force for bending operations, ensuring that the machine can handle various thicknesses and types of metal sheets. The smooth and consistent pressure from the hydraulic system enables uniform bends without deforming the material.

Bending Beams

The bending beam, also known as the ram or punch, is a critical component that directly interacts with the metal sheet. It is responsible for applying the bending force to the metal. The beam's design, including its shape and material, determines the types of bends it can produce and the thickness of the metal it can handle.

The bending beam's role is crucial in determining the quality of the bend. A well-designed beam can produce precise and consistent bends, reducing the need for post-processing and improving the overall quality of the finished product. The beam's versatility allows the machine to perform a wide range of bending operations, from simple angles to complex shapes.

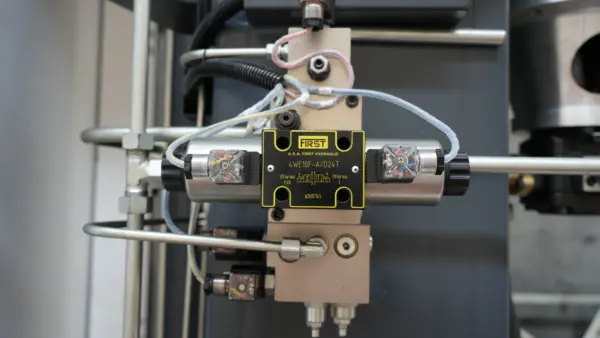

Control Systems

Modern hydraulic metal brakes are equipped with advanced control systems that allow operators to program and automate the bending process. These systems can include CNC (Computer Numerical Control) technology, which ensures precise control over the bending angles, positions, and sequences. The control systems enhance the machine's accuracy, repeatability, and ease of use.

The control systems significantly enhance the machine's performance by providing precise control over the bending process. CNC technology allows for the automation of repetitive tasks, increasing production efficiency and reducing the likelihood of human error. The ability to program multiple bending sequences and store them for future use streamlines operations and boosts productivity.

Types of Hydraulic Metal Brake Machines

Manual Hydraulic Metal Brakes

Manual hydraulic metal brakes are operated manually, necessitating an operator's direct control over the bending process. These machines rely on manual adjustments and mechanical stops to achieve the desired bends. Due to their straightforward design and operation, manual hydraulic metal brakes are ideal for simpler, less complex bending tasks. They are particularly well-suited for small workshops or businesses with lower volume production needs. While they may lack the advanced features of CNC machines, their ease of use, lower cost, and ability to handle straightforward jobs make them a practical choice for many metalworking applications.

Pros

Cost-Effective: Generally lower initial investment compared to CNC models, making them more affordable for small shops or limited budgets.

Simplicity: Easier to operate and maintain due to their simpler design and fewer electronic components.

Flexibility: Suitable for custom, low-volume work where intricate programming is not necessary.

Cons

Precision: Lower precision compared to CNC machines due to manual adjustments and potential for human error.

Speed: Slower operation since manual input is required for each bend, reducing efficiency in high-volume production.

Repeatability: Less consistent results due to reliance on operator skill and manual settings.

CNC Hydraulic Metal Brakes

CNC hydraulic metal brakes operate using computer numerical control (CNC), enabling automated and precise control over the bending process. This advanced technology allows for highly accurate bending operations with programmable sequences and angles. CNC machines are ideally suited for complex and high-precision bending tasks, as well as environments requiring high-volume production capabilities. The ability to program multiple bending sequences and adjust parameters digitally enhances efficiency and consistency in manufacturing processes. This makes CNC hydraulic metal brakes indispensable in industries demanding exacting standards and efficient production workflows.

Pros

Precision: High precision and accuracy due to computer-controlled operations, ensuring consistent and repeatable results.

Efficiency: Faster operation with automated bending sequences, increasing productivity in high-volume settings.

Flexibility: Capable of handling complex bending tasks with ease, thanks to programmable controls and advanced features.

Cons

Cost: Higher initial investment due to advanced technology and computer systems, which may be prohibitive for small businesses.

Complexity: More complex to operate and maintain, requiring skilled operators and potential for higher maintenance costs.

Dependence on Technology: Increased reliance on electronic systems, which can be susceptible to technical issues and require specialized repair services.

Conclusion: How to Choose

The choice between manual and CNC hydraulic metal brakes depends on the specific needs of the operation. Manual hydraulic brakes are cost-effective and suitable for simpler tasks, while CNC hydraulic brakes offer high precision and efficiency for complex and high-volume production. Understanding the advantages and disadvantages of each type helps in making an informed decision based on precision, flexibility, and cost considerations.

Factors to Consider When Buying a Hydraulic Metal Brake

Workload and Sheet Metal Dimensions

Assess the machine's tonnage capacity, typically ranging from 20 to over 1000 tons, to match the thickness and length of metal sheets you work with. For instance, a 100-ton brake can handle up to 10 feet of 1/4-inch mild steel, suitable for medium to heavy-duty applications in fabrication shops.

Hydraulic System Efficiency

Higher hydraulic pressures, often around 3000 psi, ensure faster bending speeds. This capability is crucial for meeting production demands efficiently. Industry benchmarks suggest that modern hydraulic brakes can achieve bending speeds ranging from 1 to 15 inches per minute, depending on the material and thickness.

Essential Safety Standards

Look for brakes equipped with safety features like dual palm buttons, light curtains, and emergency stop systems. Compliance with safety standards such as OSHA and CE ensures a secure working environment, reducing the risk of accidents. Data shows that robust safety features contribute significantly to reducing workplace incidents in metalworking facilities.

Introduction to Popular Control System Brands

control systems play a pivotal role in determining precision, efficiency, and flexibility during metal bending operations. These systems range from traditional manual controls to advanced computer numerical control (CNC) technologies, each offering distinct advantages based on the complexity of bending tasks and production volume requirements. Understanding the characteristics and functionalities of these control systems is crucial for selecting the right solution to optimize your metalworking processes. Here are some common used controller models:

Delem

Controller Models: DA-58T, DA-66T, DA-69T

Features: Known for their user-friendly interfaces, advanced programming capabilities, and precise control over bending sequences and angles.

Estun

Controller Models: E21, E200, E300

Features: Estun controllers are known for their cost-effectiveness, reliability, and user-friendly interfaces. They offer basic to intermediate programming capabilities, suitable for a wide range of bending applications in metalworking.

Cybelec

Controller Models: DNC 600, DNC 880S, ModEva 10S

Features: Offers intuitive graphical interfaces, extensive tool libraries, and adaptive bending processes for complex bending operations

ESA

Controller Models: ESA S630, ESA S640, ESA S650

Features: Known for their high precision, reliability, and flexibility in CNC control systems for hydraulic press brakes.

These controller models and brands are widely recognized for their reliability, performance, and ability to meet the diverse needs of modern metalworking industries. When choosing a controller for a hydraulic press brake, it's essential to consider factors such as ease of use, programming capabilities, support for complex bending operations, and integration with other manufacturing systems. For detailed comparison introduction of these controllers, pls cilck here to discover.

Maintenance and Care of Hydraulic Brake

Regular Inspection and Lubrication

Inspect the hydraulic system by checking hydraulic hoses, fittings, and seals for leaks or wear, and promptly replace damaged components to prevent hydraulic fluid loss and maintain pressure integrity. Additionally, apply grease or oil to mechanical components like bearings, slides, and pivot points to reduce friction and ensure smooth operation. Regular maintenance of these critical areas enhances the longevity and performance of your hydraulic press brake.

Monitor and Maintain Hydraulic Fluid

Regularly check hydraulic fluid levels and top up as needed using the manufacturer's recommended fluid. Additionally, schedule periodic changes of hydraulic fluid to remove contaminants and maintain optimal viscosity, ensuring efficient operation of your hydraulic press brake system over time. This proactive approach helps prevent issues related to fluid degradation and ensures consistent performance.

Inspect Electrical and Control Systems

Inspect electrical wiring, connectors, and control panels for signs of wear or corrosion, ensuring all connections are secure to prevent electrical issues. Periodically calibrate sensors, limit switches, and control settings to maintain accurate operation and prevent errors during bending operations. This proactive maintenance helps optimize the performance and reliability of your hydraulic press brake, minimizing downtime and enhancing overall productivity.

Maintain Tooling and Dies

Regularly inspect punch and die sets for wear, damage, or alignment issues, and clean and maintain tooling surfaces to ensure accurate bends while reducing material marking. Additionally, implement a schedule to rotate or replace tooling periodically. This practice helps distribute wear evenly and prolongs the lifespan of your tools, ensuring consistent performance and minimizing production disruptions in your hydraulic press brake operations.

Conclusion

In conclusion, investing in a hydraulic metal brake machine is a significant decision that can greatly enhance your metalworking capabilities. Whether you are upgrading your current equipment or venturing into metal fabrication for the first time, understanding the key factors such as capacity, precision, and control systems is essential.

By choosing a reputable brand like Krrass, known for its innovative bending solutions and reliable performance, you can be assured of quality machinery tailored to meet your specific production needs. Krrass not only offers advanced features and robust construction but also provides excellent after-sales support and training, ensuring that your investment delivers long-term value and efficiency in metal bending operations.