The CNC press brake price in India and market has seen significant growth in recent years, driven by the expanding manufacturing sector and increasing demand for precision metal forming. CNC press brakes, known for their computer-controlled precision and efficiency, are crucial in various industries such as automotive, aerospace, and construction. As Indian manufacturers strive to enhance their production capabilities and maintain competitive edges, the demand for advanced CNC press brakes continues to rise. This article delves into the various factors influencing the prices of CNC press brakes in India, providing insights into the current market landscape and helping potential buyers make informed decisions.

Introduction To CNC Press Brakes

CNC (Computer Numerical Control) press brakes are advanced machines used for bending and shaping sheet metal with high precision and efficiency. Unlike traditional press brakes, CNC press brakes are equipped with computer control systems that automate the bending process, ensuring consistent and accurate results. These machines can handle a wide range of materials and thicknesses, making them essential in various manufacturing sectors.

Significance In the Manufacturing Industry

In the manufacturing industry, CNC press brakes play a crucial role due to their ability to produce complex bends with minimal manual intervention. They are widely used in industries such as automotive, aerospace, construction, and electronics, where precision and repeatability are paramount. The automation and programmability of CNC press brakes reduce human error, increase production speed, and improve overall product quality.

Moreover, the flexibility of these machines allows manufacturers to quickly switch between different production runs, enhancing their ability to respond to market demands and customization requests. As a result, CNC press brakes are a vital component in modern manufacturing, driving innovation and efficiency across numerous applications.

Overview of CNC Press Brake Price and Market In India

The India press brake machine market is witnessing significant growth as industries invest in sheet metal bending and forming equipment. This market`s outlook is driven by factors such as the increasing demand for metal components in automotive, aerospace, and construction sectors, the growth of fabrication and manufacturing industries, and the adoption of press brake machines for their precision and versatility.

Additionally, the development of CNC-controlled press brakes and the rising focus on automation and digitalization in metalworking are further contributing to market growth. The market faced some impact during the COVID-19 pandemic due to disruptions in industrial activities and reduced capital expenditure, but it is expected to rebound as economic conditions improve and manufacturing activities resume.

India Press Brake Machine Market Competition 2023

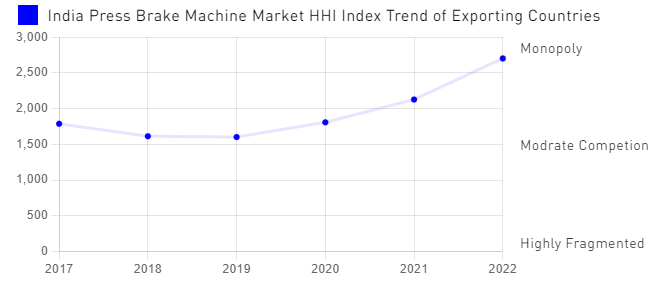

India Press Brake Machine market currently, in 2023, has witnessed an HHI of 2703, Which has increased slightly as compared to the HHI of 1789 in 2017. The market is moving towards concentrated. Herfindahl index measures the competitiveness of exporting countries. The range lies from 0 to 10000, where a lower index number represents a larger number of players or exporting countries in the market while a large index number means fewer numbers of players or countries exporting in the market.

Market Drivers

The Indian press brake machine market is experiencing substantial growth as industries seek efficient and precise solutions for sheet metal bending. This market’s positive outlook is driven by several key factors. The increasing demand for metal fabrication in sectors such as automotive, construction, and aerospace is a primary driver. Additionally, the growth of manufacturing and infrastructure industries is bolstering the market.

The adoption of press brake machines is rising due to their flexibility and accuracy in bending various materials and profiles. Furthermore, advancements in CNC-controlled and synchronized press brakes, along with a heightened focus on automation and advanced tooling, are significantly contributing to market expansion. While the COVID-19 pandemic caused some disruptions in industrial activities, the market is expected to rebound as manufacturing operations resume and the demand for fabricated products increases.

Impact of COVID-19 on the Indian Press Brake Machine Market

The Indian press brake machine market is witnessing growth as the metal fabrication industry increasingly adopts precise and automated bending solutions. This market’s positive outlook is driven by several factors, including rising demand for sheet metal components in the automotive, construction, and manufacturing sectors, as well as the expansion of infrastructure and real estate projects.

The adoption of press brake machines is propelled by their ability to perform accurate and complex bending operations. Additionally, the development of CNC-controlled and servo-electric press brake machines, coupled with a growing focus on energy efficiency and productivity, is further enhancing market growth. The COVID-19 pandemic did impact the market by disrupting manufacturing activities and causing supply chain challenges. However, the market is expected to recover as industrial operations and infrastructure projects resume.

Market Challenges

The Indian press brake machine market is growing as the metal fabrication and sheet metal processing industries increasingly demand versatile and high-precision bending solutions. This market’s promising outlook is driven by the rising demand for precision-formed metal components, the expansion of the automotive and construction sectors, and the adoption of press brake machines for their flexibility in handling various sheet metal thicknesses and lengths.

Additionally, advancements in CNC-controlled press brakes and a heightened focus on energy-efficient and automated bending processes are further propelling market growth. Despite these positive trends, the market faces several challenges. These include the need for skilled operators to program and operate press brake machines, disruptions in manufacturing activities due to the COVID-19 pandemic, and the necessity for regular maintenance and calibration of bending equipment.

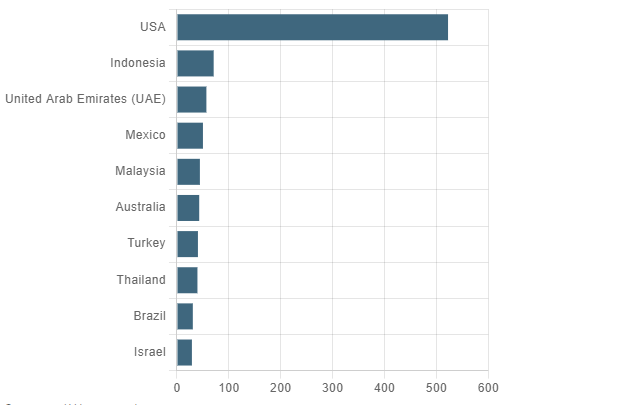

India Export Potential Assessment For Press Brake Machine Market (Values in USD Thousand)

For India Exporters of Press Brake Machine , USA seems to be the most attractive market (in 2028) in terms of export potential followed by Indonesia, United Arab Emirates (UAE), Mexico and Malaysia. Also USA and China offers high import demand potential for other countries as well in 2028.

Advantages of CNC Press Brake In India

Cost-Effectiveness: Manufacturing costs in India are generally lower due to lower labor costs and affordable raw materials. This translates into competitive pricing for Indian CNC press brakes, making them an attractive option for small and medium-sized enterprises (SMEs).

Technological Advancements: Indian manufacturers incorporate advanced CNC technology in their press brakes, offering precise control, multiple axes, and automation features. Customization options are also available to meet specific operational needs.

Quality and Durability: Indian CNC press brakes are known for their robust build and durability, capable of withstanding heavy usage over extended periods. They often adhere to international quality standards, ensuring reliability and performance.

Availability and Support: Businesses benefit from easy access to local after-sales service and support, minimizing downtime. Spare parts availability from local suppliers further contributes to efficient maintenance and operation of CNC press brakes.

Skilled Workforce: India boasts a skilled manufacturing workforce proficient in the latest technologies, ensuring high-quality production. Manufacturers also provide training and support to help businesses optimize their CNC press brake operations.

Strong Manufacturing Base: With an established industry and robust supply chain, Indian manufacturers offer innovative solutions and improvements in product design and functionality. This supports the competitiveness and export potential of Indian CNC press brakes in the global market.

What Are CNC Press Brake Price In India

CNC (Computer Numerical Control) press brakes are vital in metalworking, used for bending sheet and plate materials. The CNC press brake price in India vary widely based on factors like brand, specifications, capabilities, and additional features. Generally, the price ranges are as follows:

- Entry-Level Models: $12,000 to $30,000

- Mid-Range Models: $30,000 to $60,000

- High-End Models: $60,000 and above

Comparison of Entry-Level, Mid-Range, and High-End Models

Entry-level Models: Typically have simpler CNC controls, lower tonnage (under 100 tons), and basic features suitable for light to moderate bending tasks. Examples include models from manufacturers like Shenchong, Durmapress, or Simasv.

Mid-range Models: Offer medium to high tonnage capacities (100 tons to 300 tons or more), advanced CNC systems with more programming options, and greater precision. Brands such as Amada, Bystronic, and LVD offer popular mid-range models in India.

High-end Models: Feature advanced CNC controls with multiple axes, heavy-duty construction (300 tons and above), precision backgauging systems, and are capable of bending thick and large sheets. Models from manufacturers like Trumpf, Haco, and Salvagnini are well-regarded in the high-end segment.

Examples of Specific Models and Their Prices

- Amada Europe HFE 3i Series: A mid-range CNC press brake with prices starting around ₹70 lakhs to ₹1 crore (approximately $94,000 to $134,000 USD) depending on specifications and additional features.

- Bystronic Xpert 40: An entry-level CNC press brake with prices starting around ₹30 lakhs (approximately $40,000 USD), suitable for smaller workshops and lighter bending applications.

- Trumpf TruBend 7000 Series: A high-end CNC press brake with prices ranging from ₹1 crore and above (approximately $134,000 USD and higher), known for its high precision, speed, and versatility in heavy-duty bending tasks.

Best CNC Press Brake Price, Top Suppliers In India

1. LVD Strippit India Pvt. Ltd.

LVD Strippit is a global leader in sheet metalworking machinery and solutions. They offer a wide range of CNC press brakes known for their precision, reliability, and advanced technology. LVD has a strong presence in India, providing robust machines suitable for various bending applications across industries.

2. Amada India Pvt. Ltd.e

Amada is a renowned manufacturer of sheet metal machinery worldwide. Their CNC press brakes are highly regarded for their cutting-edge technology, high precision, and durability. Amada India offers comprehensive solutions for bending and forming processes, ensuring efficiency and accuracy in sheet metal fabrication.

3. TRUMPF India Pvt. Ltd.

TRUMPF is a leading global supplier of machine tools and laser technology. In India, TRUMPF provides state-of-the-art CNC press brakes designed to meet the demands of modern sheet metal processing. Their machines are known for innovation, reliability, and advanced control systems, enhancing productivity and quality in bending operations.

4. Bystronic India Pvt. Ltd.

Bystronic is a pioneer in laser cutting and sheet metal processing technology. They offer a range of CNC press brakes that combine precision bending capabilities with user-friendly features. Bystronic’s machines are designed to optimize productivity and flexibility in diverse manufacturing environments.

5. Sahajanand Laser Technology Ltd.

Sahajanand Laser Technology (SLTL) is a prominent player in laser and sheet metal processing solutions. They manufacture CNC press brakes equipped with advanced automation and control systems for precise bending operations. SLTL focuses on delivering high-performance machines tailored to meet specific industry needs.

6. Hindustan Hydraulics Pvt. Ltd.

Hindustan Hydraulics specializes in hydraulic press brakes and CNC press brakes. They cater to various industrial sectors with robust and efficient bending solutions. Hindustan Hydraulics is known for their reliable performance, sturdy construction, and customizable options to suit different bending requirements.

7. Yash Machine Tools

Yash Machine Tools offers a range of machine tools including CNC press brakes designed for precision sheet metal bending. They provide cost-effective solutions with a focus on reliability and performance. Yash Machine Tools serves diverse industries with flexible and efficient bending machines.

Conclusion

When choosing a supplier, consider factors such as the specific requirements of your application, the level of after-sales support provided, and the reputation for quality and reliability in the industry. It’s also beneficial to check for customer reviews and testimonials to gauge the overall satisfaction with the equipment and service provided by these suppliers.

India vs China CNC Press Brake: How To Choose?

Comparing press brakes manufactured in India versus China involves several factors that potential buyers typically consider:

Price: Generally, Chinese press brakes are known for their competitive pricing due to lower labor costs and economies of scale in manufacturing. Indian press brakes can also be competitively priced, depending on the manufacturer and specific model.

Quality: Quality can vary widely between manufacturers in both countries. Chinese manufacturers have improved their quality standards significantly over the years, but there may still be concerns about consistency and adherence to international standards. Indian manufacturers, particularly established ones, often emphasize quality and precision to compete in the global market.

Technology and Innovation: Both countries have invested in upgrading their manufacturing technologies. Chinese manufacturers may have a slight edge in adopting the latest technologies due to their robust industrial infrastructure and government support. However, Indian manufacturers also innovate and integrate advanced features into their machines.

Customization and Support: The level of customization and after-sales support can vary. Chinese manufacturers are known for offering highly customizable options at competitive prices. Indian manufacturers may focus more on providing tailored solutions and comprehensive support services.

Delivery and Logistics: Factors such as lead times, shipping costs, and logistics efficiency can impact the overall cost and feasibility of purchasing from either country, especially for international buyers.

Brand Reputation: Both Indian and Chinese manufacturers have established brands with varying degrees of reputation in the global market. Established brands typically offer more reliability in terms of product performance and customer service.

Future Price Trend of CNC Press Brake In India

Economic conditions such as growth rates, inflation, and currency fluctuations significantly influence the manufacturing costs of CNC press brakes. Stable economies generally support predictable pricing trends, whereas economic volatility can lead to unpredictable cost fluctuations.

Technological advancements in automation, robotics, and digitalization play a crucial role in enhancing production efficiency and potentially lowering costs over time as these technologies become more mainstream and affordable. Supply chain dynamics, including raw material costs and global trade policies, also impact overall cost structures, influencing pricing strategies adopted by manufacturers in India and China.

Looking forward, the future pricing of CNC press brakes in India will depend on how effectively the manufacturing sector adapts to technological advancements, navigates global economic conditions, and responds to evolving market demands. Monitoring these factors closely through industry reports and expert insights will provide a clearer understanding of the direction of pricing trends in this dynamic market.

Reviewed by 2 users

Thank you for this press brake to expand our business, good machine!

press brake

Very good and very stable machine from KRRASS