Instructions

This equipment is for Digital Sheet metal Grooving Machine,and with advanced technology of CNC controller and high machining precision .The operation is simple .No noise No vibration, etc. The v grooving machine for sheet metal is used for sheet metal parts( such as stainless steel board,aluminum board ,aluminum copper board ,Yakeli board and other special board).The working principle is that grooving V-type 、 U-type and anomaly types. It`s especially suitable for grooving V-type before bending metal plate.

Performance and characteristics

1 RAS Series Digital Sheet Grooving Machine is the product Upgraded Based on the Sheet metal grooving machine at home and abroad by the Research Specialist Staff in Krrass company. This machine has all the performance of traditional models, and adequately address the customer in a series of problems encounteredin the process of actual operation.

2 Adopts steel plate welding , relieves of internal stress of this equipment and exceeds the same products both at home and abroad about the Strength, stiffness and stability.

3 Adopts feeding materials structure after equipment ,and with the clever design of the universal ball.So the surface of the sheet metal are won`t destroyed at the time of feeding and discharging .Adjustable movable workbench,and to ensure the accuracy of every part slot depth at the same time of grooving.

4 The equipment adopts three molding knife before and after processing,and greatly reduced scrap iron during the processing of working.Compared with the traditional five knife machining precision is also greatly improved.

5.The equipment adopts full pneumatic clamp and swaging ,Working fast, Products without clamp mark,with illuminating system.

6 The equipment adopts high speed steel pinion and rack Large pitch ball screw, And high precision mute linear guide High torque servo motor and imported planetary reducer as a driver. Rest is more stable and quick when machining.

7 Equipment table adopt high strength plate as the base surface,and the workbench when machining, not easy to be wear and tear.Adjustable and panel and fuselage artifacts use activities,and precision between 0.02mm.

8 Equipment used THE CNC CONTROLLER. Operator easy-to-learn, accurate positioning.

9 Equipment clamp pressure material adopts full pneumatic control,Make the machine met a high in energy conservation and environmental protection concept.

10 V grooving machine for sheet metal modelling concise and easy appearance overall equipment, USES the frame structure,In all kinds of technical personnel operating habits.The operators at work can fully meet the requirements of production and technology.

Main technical parameters

Main equipment configuration

Introduction of the structure

The V grooving machine for sheet metal has compact structure and reliable performance. It is easy to operate.Wall adopts frame structure, permanent deformation

Mainly made up of three groups: Servo motor drive system, Pneumatic clamp system, the main steel frame

(I) Y axis

(1)3kw: DELTA ac servo motor

(2)Machine of decelerate of planet of synchronous belt

(3)synchronizing wheel, High precision gear and rack, linear guideway FUNCTION: the capability of providing plane pin

(II) X axis

(1)2kw: DELTA ac servo motor

(2)Machine of decelerate of planet of synchronous belt

(3)synchronizing wheel, High precision gear and rack, linear guideway

(4)clamp

FUNCTION: For the towed behind institution accurate positioning.

(III) Z axis

(1)2kw: DELTA ac servo motor

(2)Machine of decelerate of planet of synchronous belt

(3)synchronizing wheel, High precision gear and rack, linear guideway

FUNCTION: To provide accurate positioning power tool rest institutions

(IV) pneumatic system

(1)Retainer pneumatic system

Function: Provide the last keep-off dragging plate clamping force

(2)Clamp the pneumatic system

Function: For plane groove clamping plank before, to be prepared for the planning.

(V) electrical control system

CNC, AC SERVO, electrical apparatus element, electric appliance cabinet etc.

(VI) Maintenance

(1)Periodically check all fasteners are loose.

(2)Every day before use must refill the lithium base grease in the transmission parts.

(3)Using slot machine, pay attention to the temperature of driving part and the sound.

(4)Check the grounding of the motor are in good condition.

(5)The machine is composed of three sets of servo motor drive system,Is equipped with overload short circuit protection.

About Controller

General structure of controller

Panel of HUST-H6DKV-3 Series

LCD panel of HUST-H6DKV-3 Series

CPU host interface(back –sight)

* I/O Connect Board (PC Board No.:H6DSIOIOV1_2, AB852)

- I/O connect board controls 24 input terminals and 16 output terminals.

- Output control is by 0V output.

- An INPUT can be of NPN type or PNP type.

- When NPN and PNP are in use at the same time, (1) NPN:the input voltage at I is 0V. (2) PNP:the input voltage at I is 24V.

- Input current at I: 3.6mA.

- Output current at O: 100mA (H6DCPUV6_1 : 250mA).

- +24 V power supply must be provided by an external.

Fig 4-2 I/O interface connector Description (NPN-PNP both using)

Figure I / O input / output interface connector pin assignment (NPN type)

Controller Structure Description

(VII) User instructions

1.0pen

Open the electrical box to the right of the air switch, and open the key switch on the front panel, the machine into the energized state, the system enters the picture below:

press the corresponding function key F1 automatically entered under automatic operation mode.

- Press the corresponding function key F3 entered manual operation.

- Press the corresponding function key F6 set parameters into the design parameters of the picture.

- Press the corresponding parameter in read F8 function key to enter the read parameter screen.

This V grooving machine for sheet metal provides: Y-axis movement slotted turret around; X-axis beam back and forth motion of the positioning groove spacing; Z axis movement up and down the slot depth turret positioning

Note: Each turn, before the machine action must be X-axis, Y-axis, Z-axis homing.

2.Automatic mode

In the boot screen, press the corresponding function key to enter the automatic mode automatic operation mode, the picture is as follows:

After pressing the execute button to straighten the sheet "Start" to start processing programs, fixed binder foot pressed, X-axis operation of the first slot position, the depth of the first cut to the next turret turret servo drive (Y-axis) movement from right to left, reaches the set length gouging turret lift and return to the right side of the machine. If the depth is not reached the set value, the turret and then move down to the next knife slotted knife, with the first knife. After reaching the depth of the set up, activities binder presser foot release, knife back to square one, while X-axis beam to move to the next slot action with the first slot. So back and forth cycle, open to the starting position after the machine automatically .

In automatic screen will display the current X-axis, Y-axis current coordinates, Z-axis, and the total length of the plate, set the depth and the current depth, and the second several times, the first of several slots, the current group number.

Press the F5 function key to enter the set speed automatic speed setting screen.

Be set separately to run automatically when the Y-axis speed, slotted speed Z-axis and X-axis speed and the X-axis return rate (rapid return), etc.

Data setting method : move the cursor to where you need to modify the cursor keys on the control panel, type the desired speed value by data input button on the control panel, press the "losers,Enter "key to confirm the set value, and if they make a mistake, press the" Clear "key to delete the post, re-enter.

depending on the processing of sheet metal processing technology to choose whether to open the coolant. If you need to "Coolant select" Set as one; otherwise set to 0.

After completing the above parameter settings, press the function returns the column corresponding to the F8 key to return to the automatic screen.

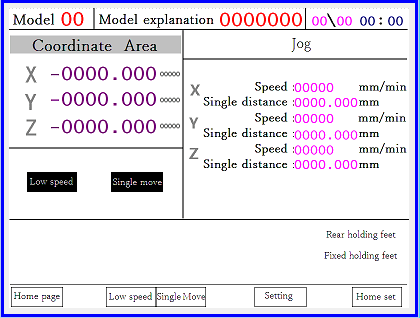

3.Manual mode

In the boot screen, press the corresponding function key to enter the automatic mode automatic operation mode, the picture is as follows:

This machine provides: Y-axis movement slotted turret around; X-axis beam back and forth motion of the positioning groove spacing; Z axis movement up and down the slot depth turret positioning.

Press each “X”, “Y”, and “Z” key, planer, beams and servo turret were homing.

F2 function key to switch the low-speed / high-speed, F3 function key to switch interlock / single action.

Each time you boot, are required for homing Remedy: Press the “Start” button to return to the origin of the three axes simultaneously

Press the “Insert” key, fixed binder foot solenoid valve action.

Press “Enter” key, evacuation feed presser foot solenoid valve action.

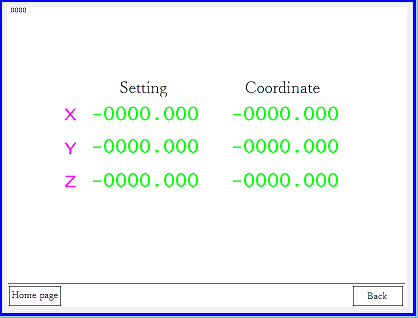

In manual mode, if you press the function key compensation F8, will enter the home setting screen, the picture below:

Screen, the following parameters need to be set.

Y-axis: after gouging homing distance from the knife point and mechanical origin (negative).

X-axis: After homing beam, plate clamping the front position, generally 0.

Z axis: height (negative) to the lowest point of the knife block.

Press the function key on page F8, return to manual mode screen.

In manual mode, if you press the function key under the speed F7, enter manual speed setting screen.

Manual speed setting on the screen.

X, Y, Z axis high-speed, low-speed, single-action distance.

Press the function key F8, return to manual mode screen;

Speed setting method is as follows: By controlling the cursor keys to move the cursor on the control panel to the need to modify the place, typing speed value required by data input button on the control panel, press “Enter” to confirm the value of the set, and if the input when the error, press the “Clear” after deleting, re-enter.

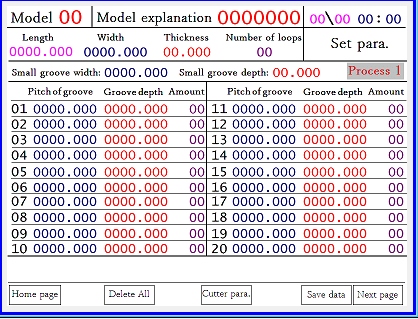

4.Set parameters

Press to enter the parameter setting mode of operation parameters corresponding to the function keys located under the column in the boot screen, set the following parameter screen :(Unit: MM)

In the main screen, set the parameter to set the following parameters:

Process Number: setting process different plate numbers;

Total plate length, total plate width, total thickness, plate number;

Width: The distance between the two slots;

Groove depth: The depth of each groove track;

Knife count: the number of open slots per channel knife;

After setting the appropriate parameters finished, press the Save function key F7, save the current parameters to the corresponding process number;

Group refers to the current setting of parameters which exist among groups, this controller can store a total of 10 sets of parameters, which ranges from 1 to 10, via the cursor keys and page keys to the parameters to be set, the corresponding region will brighten, input data with other data input methods, you can refer to the previous the introduction.

Process numbers are used for ease of distinction, you can enter the name of the current process of setting parameters of the plate. Which is a combination of numbers, a thickness of the slotted plate thickness, the maximum thickness of the sheet 6MM, minimum 0MM. Plate width is the width of the slotted plate, a cycle refers to the number of plates slotted knife refers to the number of cycles for each slot. Width is the width of each slot, as per slot only once, then the number must be set to a knife. Once analogy.

Back Home Next press the corresponding function key, you can return to the start-up screen.

Press the corresponding function key under the full deletion, it will restore the parameters for all groups 0.

After setting up the parameters for all slots of the confirmation, press to save the column corresponding to the function keys on the parameters set by groups will be saved, press the save button on all three parameter settings are equivalent.

Next press the corresponding function key bar under, you will see the other two-page set of parameters, can be returned by previous.

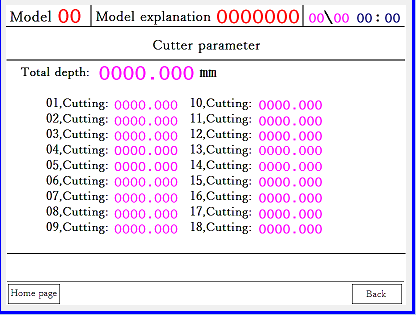

Press the F5 function key to enter the parameters knife knife parameter setting screen.

Total depth: for example, the total depth of 1.00mm; can be divided into a first blade 0.2mm, a second knife 0.5mm, the third blade 0.3mm; and so on.

Note: For each of the groove depth, the knife is only one parameter, it is necessary to find a suitable knife parameters of each groove depth.

A total of 18 knife blade parameter, wherein the first cutting up to 0.5mm, while if it exceeds its maximum value, the maximum value will have been executed, or not accepted. Final cut of up to 0.05mm, in actual use, please note that the technological requirements of slot machines.

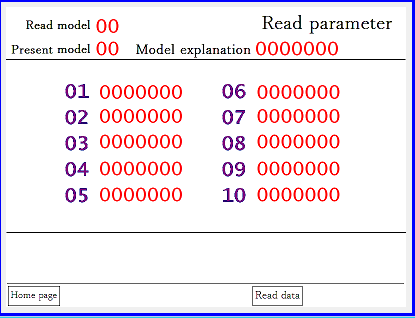

5.Reading parameters

Press the corresponding parameter field next read function keys in the boot screen to enter the read operation mode parameters, parameter screen read as follows:

When setting parameters in reading groups read screen, press the function key read F6, read the corresponding process parameters, in a total of 10 sets of data read parameters, when the machine which has been slotted to save all parameters in the boot screen, press By reading the parameters corresponding to the next column to read parameter function key to enter the operating mode.

Common Faults and exclusion

Servo Fault information table

Commen alarm

ERROR-02 SERVO ALARM, PLEASE HOME AGAIN

Information:

Position servo loop system generates an error. The situation of generating an error would be:

Controller to send commands too fast, with the servo motor can not respond to;

2.The controller does not receive feedback signal. That servo motor may alarm;

Remedy:

1.Please check the program, F value is set too large;

2.Resolution set whether error;

3.Check the machine or motor is blocked or not. Check the wiring.

ERROR-20 AXIS OVER TRAVEL

Information:

Axial tool than hardware range of travel restrictions.

Remedy:

Use manually move the axis to the working stroke within.

ERROR-22 ERROR-22 EM-STOP, HOME AGAIN

Information:

The controller is currently in an emergency stop state.

Remedy:

After removing the condition, turn on the emergency stop button, press the RESET button.

Learn more about our products, please visit and subscribe to our Youtube channel