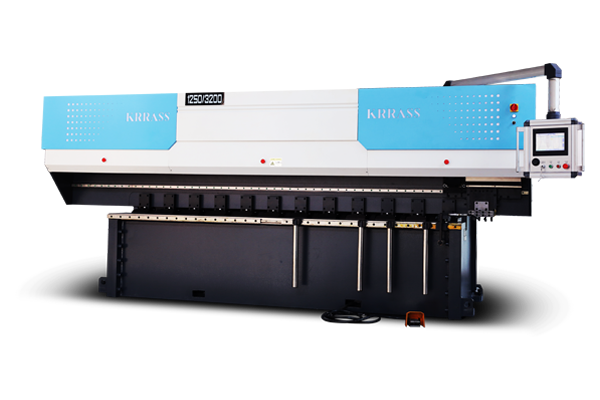

Vertical V Grooving Machine

Sheet Metal V Groover

Vertical V Grooving Machine is good at metal sheet accurate grooving,which is good for controling the radius of the bending angle in the subsequent bending process.

Top performances allow to accurately and cost-efficiently V Groover pieces in high volumes.

Proportional oil hydraulic circuit has been completely designed by KRRASS. It is optimized for every V Grooving Machine size, with high-quality and reliable parts.

Vertical V Grooving Machine is available in a wide range of models and powers. Length and shearing thickness can be customized to the highest levels in the category.

- Controller: HUST CNC Controller - Taiwan

- Serivo Motor: Panasonic - Japan

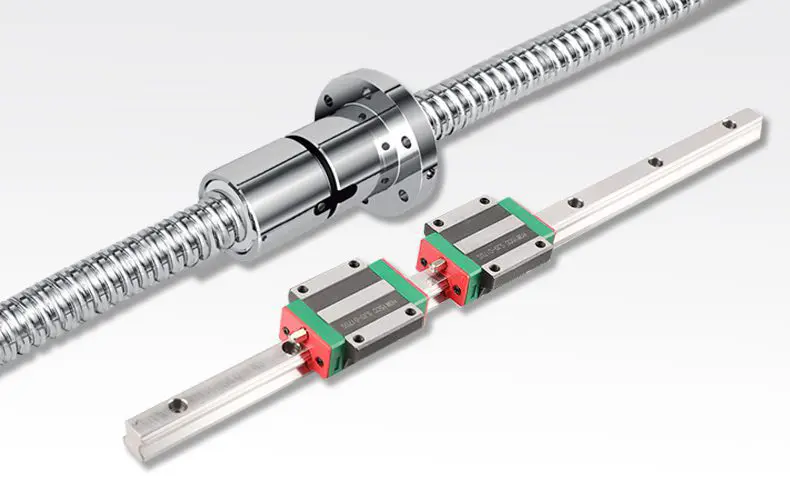

- Hight-Precise Ball Screw: HINWIN - Taiwan

- Hight-Precise Linear Guide Rail: HINWIN - Taiwan

- Gear-rack drive: YYC - Taiwan

- Touching Ball Bearing: NSK - Japan

- Grooving Cutter: KORLOY - Korea

- Electrical Element: AIRTAC - Taiwan

- Air Cylinder: AIRTAC - Taiwan

- Power Cable: IGUS - Germany

Standard Equipment

Introduction to Configuration

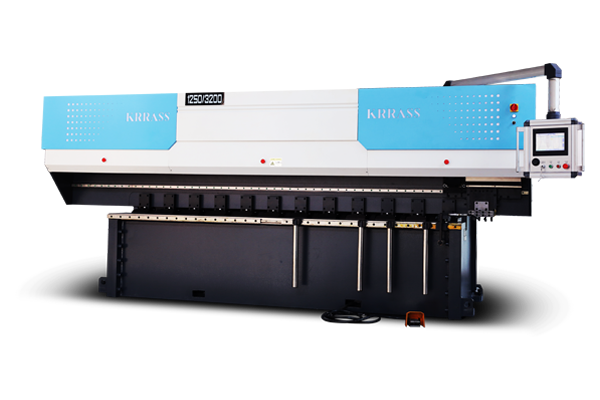

Stable Accurate Quiet

The frame steel plate is processed by a large gantry center with hight precision.The frame is processed by automactic welding equipment,and the welding seam is uniform.This ensures the high rigidity of the entire frame.

HUST CNC Control System

HUST CNC A60C Control

- 15 inch CNC touch display

- Acceleration / deceleration response time: 0.5US

- With fallback function

- PLC interrupt function: scan time is

- Fixed at 10ms

- Avoid collision

Accurate Back Support Device

The Plate is fed into machine by back clamp on back support device,And the feeding tolerance is ≤±0.03mm.The Plane of the pallet is strengthened to make it more wear-resistant.

More Details of Sheet Metal V Groover

Technical Parameter of Vertical V Grooving Machine

| Content | Required Parameter | Required Parameter | Required Parameter | Required Parameter | Required Parameter |

|---|---|---|---|---|---|

| Model | HRK1250-3200 | HRK1250-4000 | HRK1500-3200 | HRK1500-4000 | HRK2000-4000 |

| Plate Thickness | 0.4-6mm | 0.4-6mm | 0.4-6mm | 0.4-6mm | 0.4-6mm |

| Plate Length X Width | 1250x3200mm | 1250x4000mm | 1500x3200mm | 1500x4000mm | 2000x4000mm |

| Grooving Speed/Speed is changeable or not | 5M-70M/min ( The speed is changeable) | 5M-70M/min ( The speed is changeable) | 5M-70M/min ( The speed is changeable) | 5M-70M/min ( The speed is changeable) | 5M-70M/min ( The speed is changeable) |

| Feeding Speed | 0.5-20M/min | 0.5-20M/min | 0.5-20M/min | 0.5-20M/min | 0.5-20M/min |

| Min. Setting Unit in Y-axis | 0.01mm | 0.01mm | 0.01mm | 0.01mm | 0.01mm |

| Positioning Precision in Y-axis | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

| Min. Setting Unit in X-axis | 0.01mm | 0.01mm | 0.01mm | 0.01mm | 0.01mm |

| Positioning Precision in X-axis | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

| Min. Setting Unit in Z-axis | 0.01mm | 0.01mm | 0.01mm | 0.01mm | 0.01mm |

| Positioning Precision in Z-axis | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

| X-axis Motor Power | 4.5KW | 4.5KW | 4.5KW | 4.5KW | 4.5KW |

| Y-axis Motor Power | 2KW | 3KW | 4KW | 5KW | 2KW |

| Z-axis Motor Power | 0.4KW | 0.4KW | 0.4KW | 0.4KW | 0.4KW |

| Workbench Planeness | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm |

| Feeding Way | Back feeding | Back feeding | Back feeding | Back feeding | Back feeding |

| Workbench is replaceable or not | Replaceable ( Exchangeable as well ) | Replaceable ( Exchangeable as well ) | Replaceable ( Exchangeable as well ) | Replaceable ( Exchangeable as well ) | Replaceable ( Exchangeable as well ) |

| Workbench is quenched or not | Yes | Yes | Yes | Yes | Yes |

| Number of Cutter | 4 PCS | 4 PCS | 4 PCS | 4 PCS | 4 PCS |

| Max. Depth for one-time Grooving | 1.0mm | 1.0mm | 1.0mm | 1.0mm | 1.0mm |

| Max. Grooving Depth | 3.0mm | 3.0mm | 3.0mm | 3.0mm | 3.0mm |

| Outline Dimension | 5000*2500*2100mm | 5800*2500*2100mm | 5000*2750*2100mm | 5800*2750*2100mm | 5800*3250*2100mm |

| Weight | 9500kg | 10500kg | 10200kg | 11200kg | 11600kg |

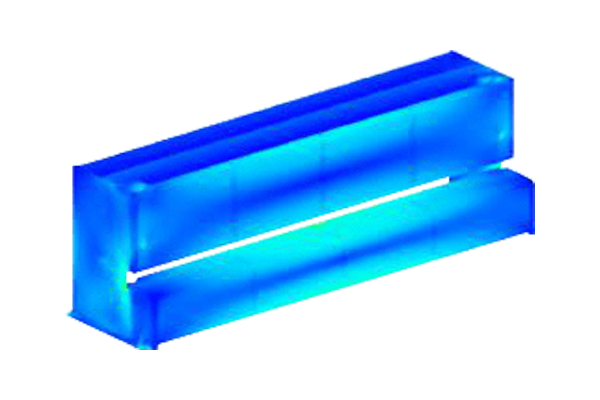

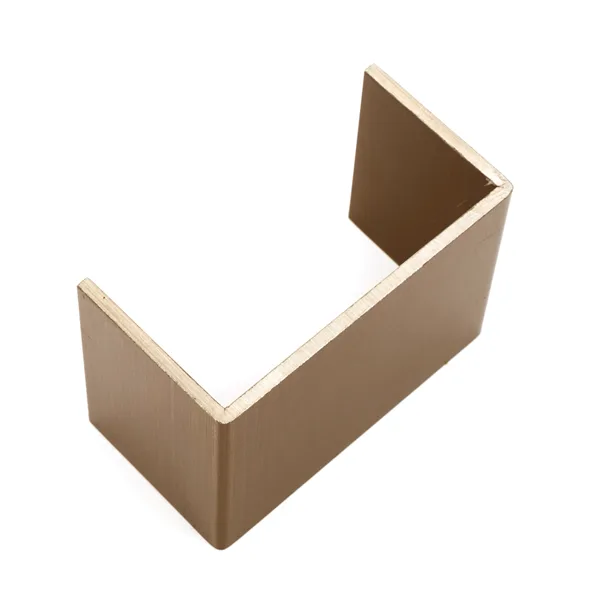

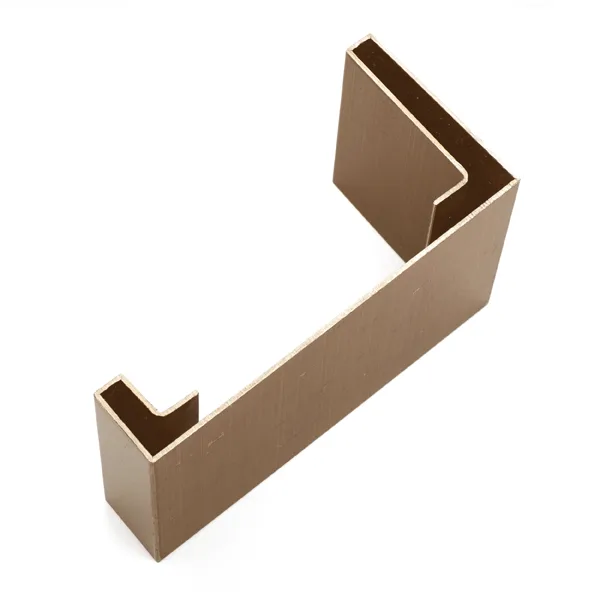

Slotting Case of Sheet Metal V Groover

Reviewed by 9 users

HRK-1500×3200 Vertical V Grooving Machine es muy bueno, satisfacer mis necesidades

Машина прочная и долговечная, надежная и долговечная. Я восхищаюсь универсальностью этой машины, потому что она может обрабатывать металлические пластины различной толщины. С вертикальной V – образной нарезной машиной с ЧПУ на металлических пластинах KRRASS я могу добиться профессиональных результатов в своих проектах по обработке металлов.

Krrass metal plate HRK series vertical CNC V – sloter est un changeur de jeu absolu pour notre entreprise. Nous utilisions auparavant des méthodes manuelles pour tracer et rainurer des rainures en V sur le métal, et le processus était lent et fastidieux. Cependant, avec cette machine, nous sommes maintenant en mesure de fabriquer des V – slots précis avec précision et rapidité et d’augmenter notre productivité. La technologie CNC assure une fabrication de rainures de haute précision. Cette machine est facile à utiliser et à entretenir, ce qui augmente considérablement notre capacité de production.

Как металлист, я всегда ищу инструменты, которые облегчат мою работу. Эта вертикальная V – образная нарезка с ЧПУ KRRASS HRK – 1250 * 3200 изменила мои правила игры.

Very good quality, I hope to cooperate with KRRASS again.