W11 3-Roll Plate Roller Machine

High Standard 3-Roll Sheet Metal Roller Bender

The W11 Series Sheet Metal Roller Bender is mighty and uses a pyramidal linear guide for bending rollers, which enables it to achieve the best bending results without guaranteed power loss. In the plate roller machine model W11, all three rollers use independent hydraulic gear motors directly coupled to the rolling roller shaft, which can ensure the superiority of torque and speed of these 3 Roller Rolling Machines.

Standard Manual Drop-End

Optional Control Panel with digital read-out

Tailored-made Plate Bending Machine

Standard Equipment

- Two motorised rolls

- Induction hardened rolls

- Polished roll surface

- Motorised pre-bending and bending

- Bending roll tilt

- Rolls with extensions for bending profiles

- Mobile pedal controls

- Emergency barrier around the machine

- CE certified machine

Optional features

- Profile section bending rings

- Numerical controls

- Version with vertical rolls

- Central and side supports

- Machine ready for hot rolling

- Version with planetary guides (3HEP)

- Special colours

More Details of 3 Roller Rolling Machine

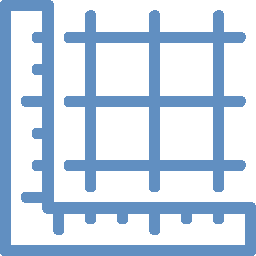

Technical Parameter of Plate Bending Machine

| Name | Max Rolling Thickness | Max Rolling Width (mm) | Min Rolling Diameter (N/mm) | Yield Limit (N/mm2) | Rolling Speed (m/min) | Upper Roller Diameter (mm) | Lower Roller Diameter (mm) | Lower Roller Center Distance (mm) | Main Motor Power (Kw) | Weight (Kg) | |

| <450N/mm2 | <700N/mm2 | ||||||||||

| W11-4/1500 | 4 | 2.5 | 1500 | 187.5 | 245 | 5 | 150 | 140 | 200 | 4 | 1700 |

| W11-4/2000 | 4 | 2.5 | 2000 | 200 | 245 | 5 | 160 | 150 | 220 | 4 | 2000 |

| W11-6/1500 | 6 | 4 | 1500 | 200 | 245 | 5 | 160 | 150 | 220 | 4 | 2200 |

| W11-6/2000 | 6 | 4 | 2000 | 212.5 | 245 | 5 | 170 | 160 | 220 | 5.5 | 2500 |

| W11-6/2500 | 6 | 4 | 2500 | 225 | 245 | 4.5 | 180 | 170 | 250 | 5.5 | 2600 |

| W11-8/1500 | 8 | 5 | 1500 | 212.5 | 245 | 5 | 170 | 160 | 220 | 5.5 | 2400 |

| W11-8/2000 | 8 | 5 | 2000 | 225 | 245 | 4.5 | 180 | 170 | 250 | 5.5 | 2500 |

| W11-8/2500 | 8 | 5 | 2500 | 300 | 245 | 4.5 | 240 | 180 | 280 | 7.5 | 4000 |

| W11-12/2000 | 12 | 8 | 2000 | 300 | 245 | 4.5 | 240 | 180 | 280 | 7.5 | 3500 |

| W11-12/2500 | 12 | 8 | 2500 | 325 | 245 | 4.5 | 260 | 220 | 320 | 11 | 5300 |

| W11-12/3000 | 12 | 8 | 3000 | 350 | 245 | 4 | 280 | 240 | 360 | 11 | 7500 |

| W11-16/2000 | 16 | 10.5 | 2000 | 325 | 245 | 4.5 | 260 | 220 | 320 | 11 | 4800 |

| W11-16/2500 | 16 | 10.5 | 2500 | 350 | 245 | 4 | 280 | 240 | 360 | 11 | 6700 |

| W11-16/3000 | 16 | 10.5 | 3000 | 425 | 245 | 4 | 340 | 270 | 440 | 15 | 10300 |

| W11-20/2000 | 20 | 13 | 2000 | 350 | 245 | 4 | 280 | 240 | 360 | 11 | 6500 |

| W11-20/2500 | 20 | 13 | 2500 | 425 | 245 | 4 | 340 | 270 | 440 | 15 | 9300 |

| W11-25/2000 | 25 | 16.5 | 2000 | 425 | 245 | 4 | 340 | 270 | 440 | 15 | 8600 |

| W11-25/2500 | 25 | 16.5 | 2500 | 462.5 | 245 | 4 | 370 | 280 | 480 | 22 | 11000 |

| W11-30/2000 | 30 | 20 | 2000 | 462.5 | 245 | 4 | 370 | 280 | 480 | 22 | 10000 |

| W11-30/2500 | 30 | 20 | 2500 | 525 | 245 | 4 | 420 | 360 | 550 | 30 | 16000 |

| W11-30/3000 | 30 | 20 | 3000 | 187.5 | 245 | 4 | 150 | 390 | 600 | 30 | 18500 |

| W11-40/2500 | 40 | 26.5 | 2500 | 625 | 245 | 4 | 500 | 400 | 600 | 37 | 20000 |

Reviewed by 12 users

I was able to easily roll metal sheets with precision and accuracy, which has saved me a lot of time and effort. This machine is a great investment for any metalworker or DIY enthusiast who requires a reliable and efficient rolling machine.

I appreciate the machine’s durability, which ensures that it will last for a long time. The machine is very easy to use and the user manual that came with the machine was very helpful in getting me started. This machine is a great investment for anyone who needs to roll metal sheets regularly.