WC67K Series Hydraulic Press Brake with E21 Controller

Hydraulic Press Brake (E21 Controller)

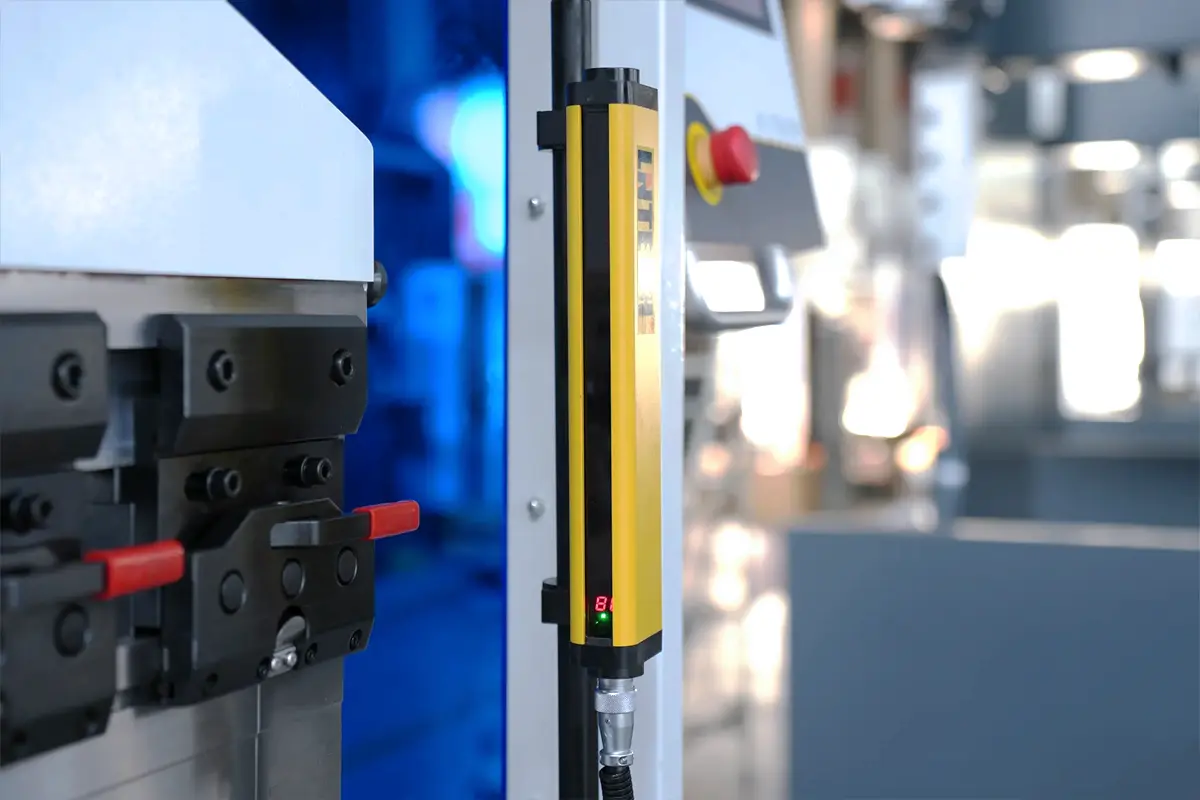

Hydraulic Press Brake with E21 Controller with its easy-to-use control unit, rigid body frame, flawless design, high efficiency, multiple tool usage solutions, top CE safety standards, and a suitable price range make it the best-in-class world leader. It is ideal for bend-sensitive, energy-efficient solutions.

Simple and solid Hydraulic Press Brake

Work area can be customized and all types of tool clamping can be installed

Tailored-made Hydraulic Press Brake

- Controller: Estun E21

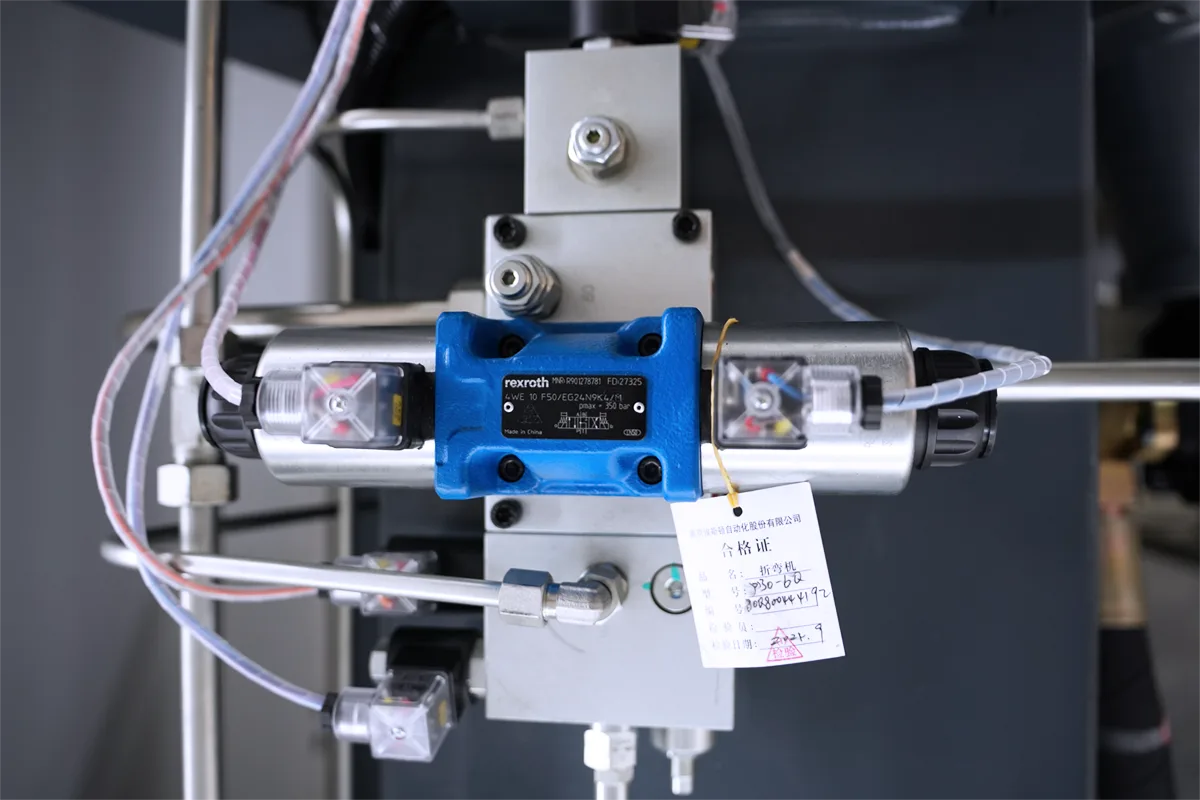

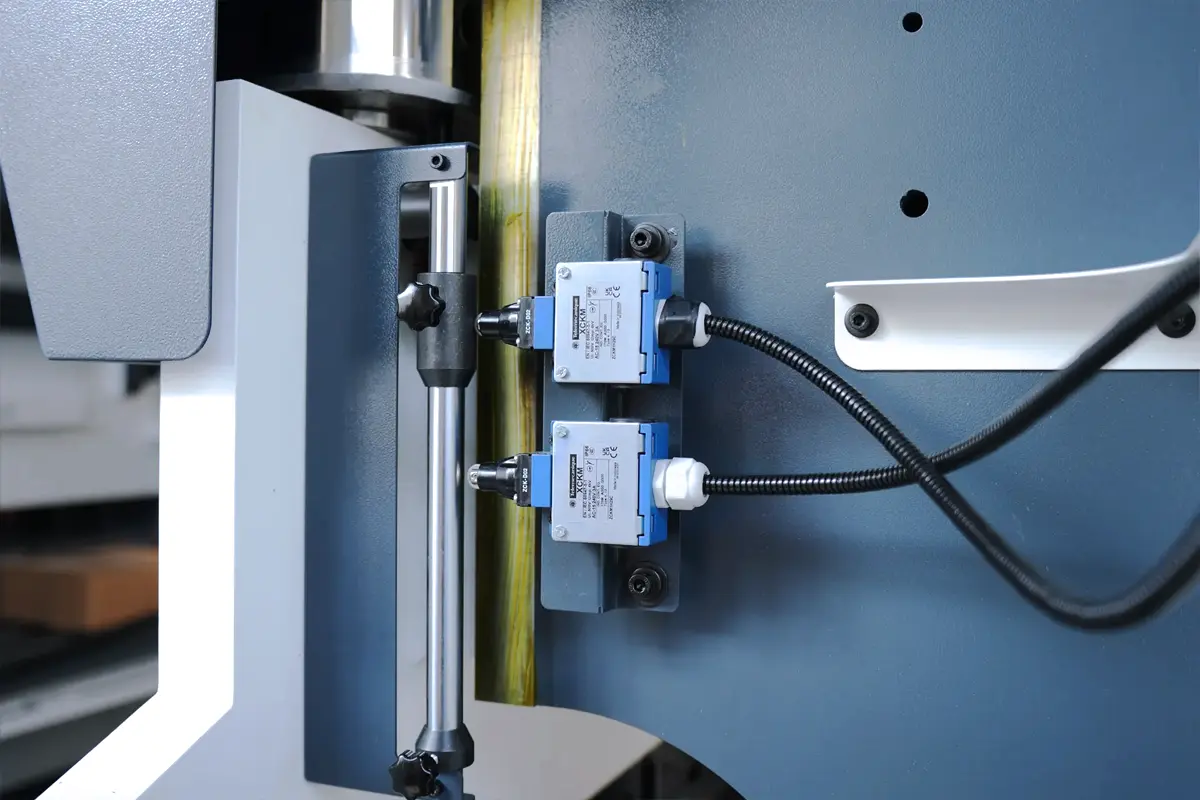

- Electrics: Schneider Electric - France

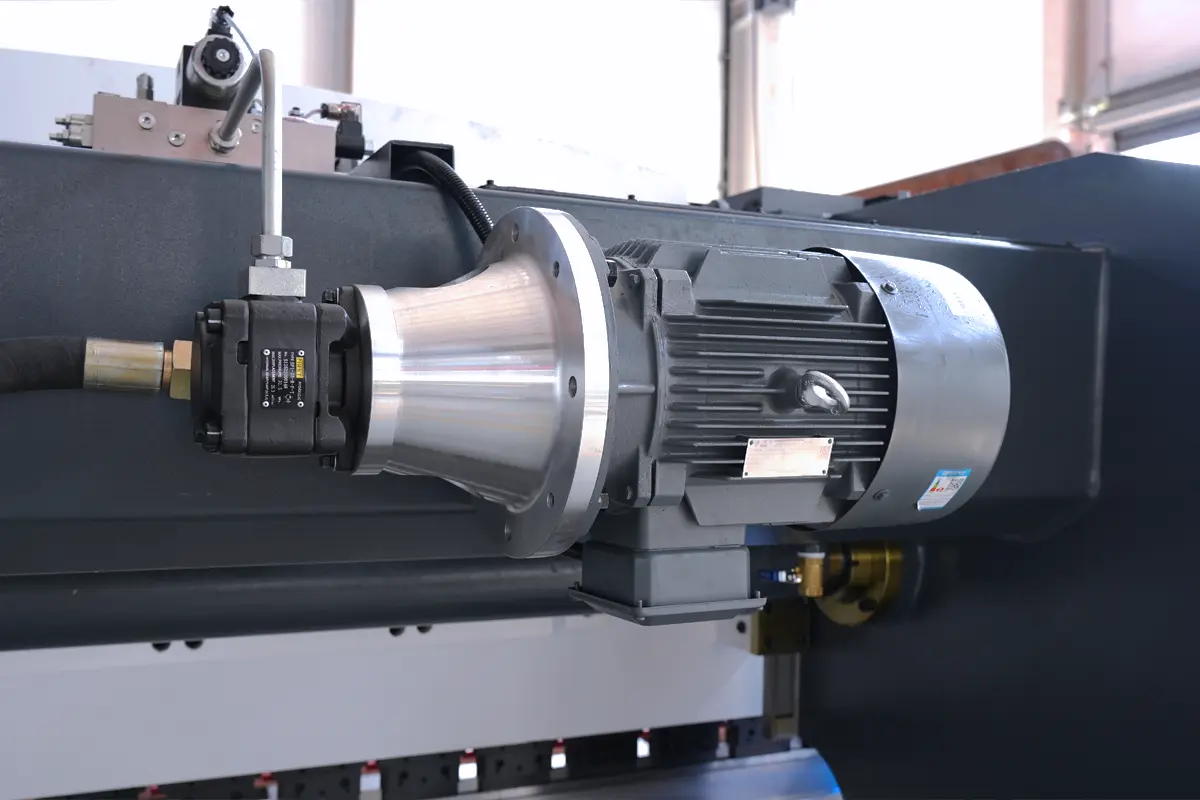

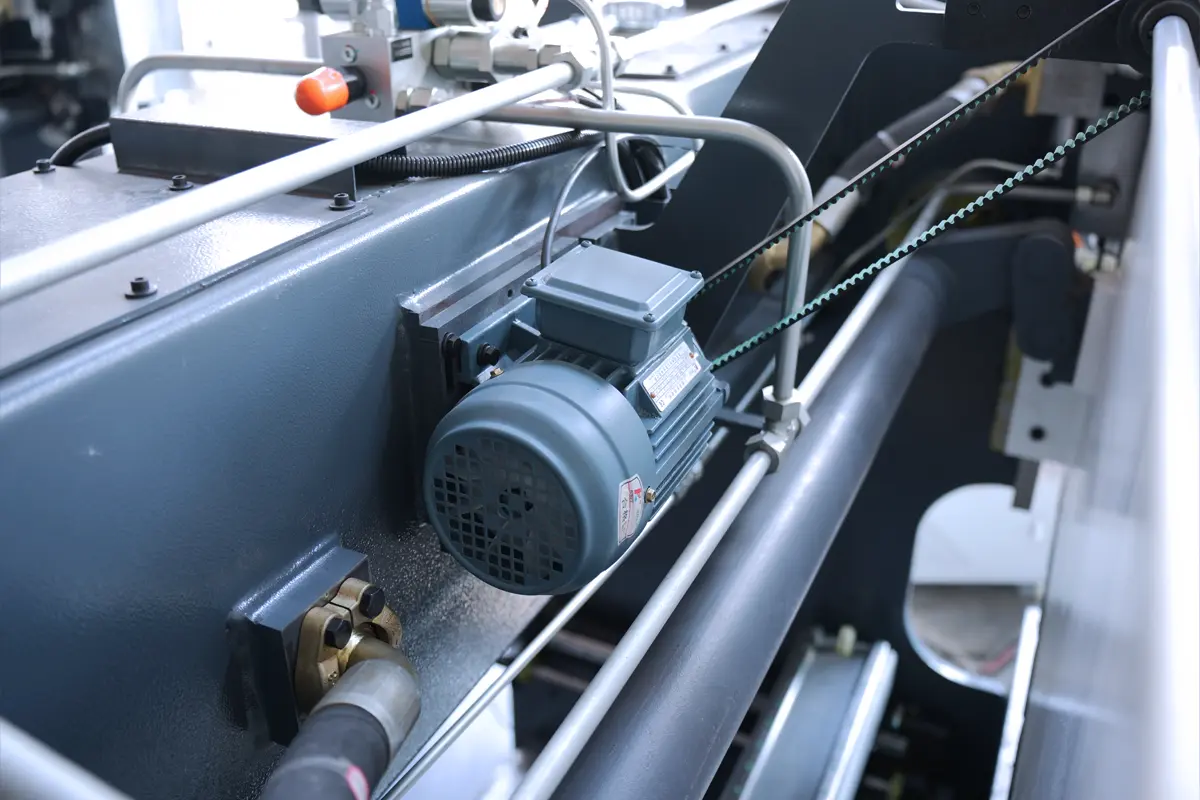

- Main Motor: Siemens Motor - Germany

- Servo Motor: ESTUN

- Foot Switch: KACON - South Korea

- Hydraulic System: FIRST - USA

- Oil Pump: FIRST - USA

- Sealing Ring: PARKER - America

- High Efficiency Motor - Class IE3

- Tube Connector: EMB - Germany

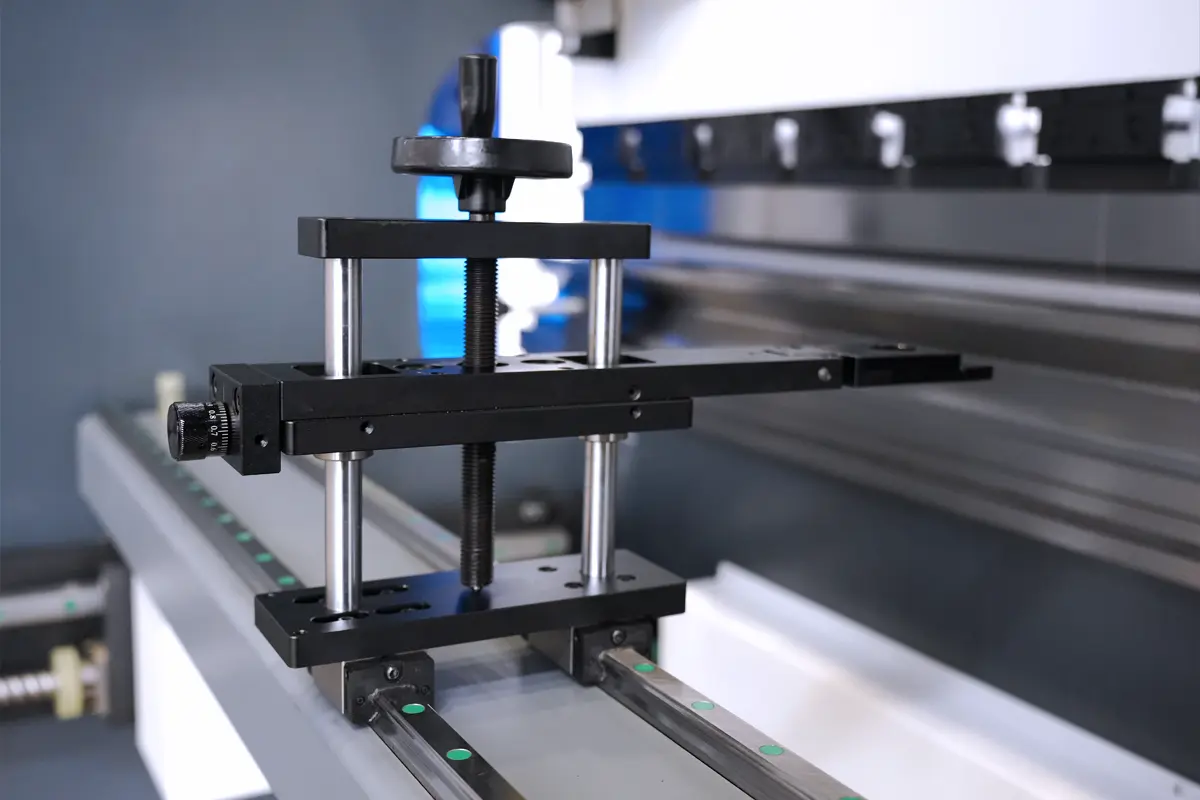

- Backgauge: SHAC - Taiwan

- Y-axis travel switch: Schneider

Standard Equipment

Introduction to Configuration

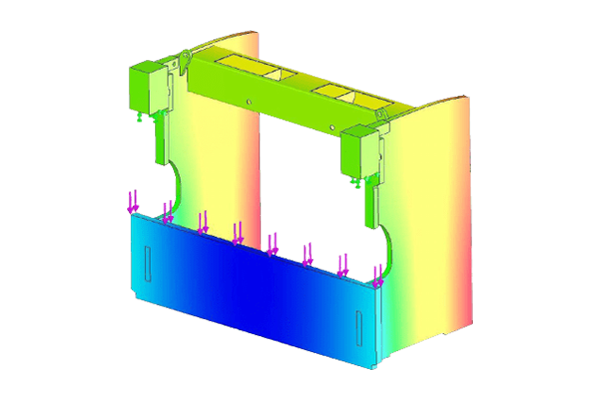

FEA & Stress Analysis

Stress Analysis & Finite Element Analysis

The CAE software SOLIDWORKS used as the method to analyze the linear static construction, stress and deformation for press break and laser cutting machine frames. So for complicated structures, highly complex loading’s, transient modelling and combination of the above.

ESTUN NC Control System

ESTUN E21 Control

- Backgauge control

- Control the common motor or inverter

- X&Y-axis intelligent positioning

- Multi-step programming, 40 programs, each program 25 steps

- Built-in time relay function

- One-button function switching

- Unilateral positioning function

- A key backup and restore of parameters

- Chinese and English

- Metric system

Why KRRASS Hydraulic Press Brake?

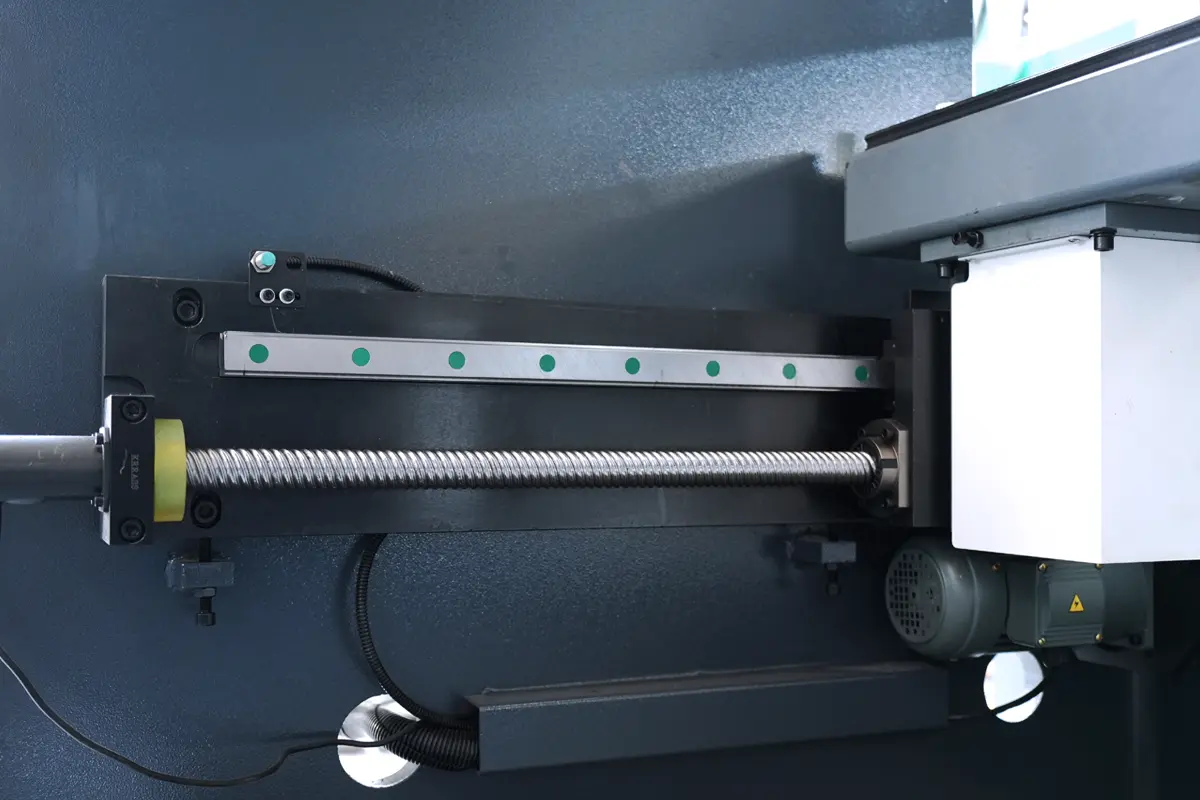

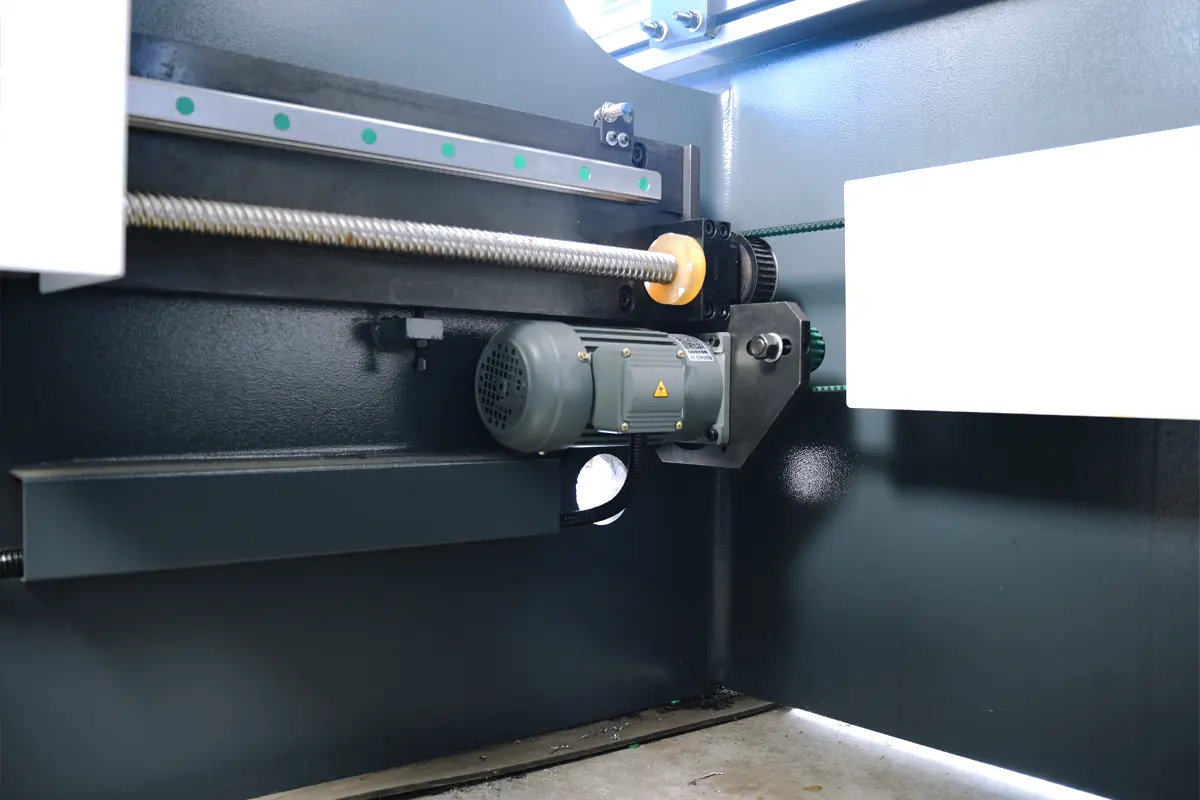

Hydraulic Press Brake Back Gauge System

One of the most important factor for bending capacity is the design of back gauge and stability. Quality cutting is possible with perfect product,stabilty and precision back gauge.

The high speed ballscrew back gauge system movement is also supported with linear guides, which helps the back gauge achieve long life, greater sensitivity and strengthens against any collisions.

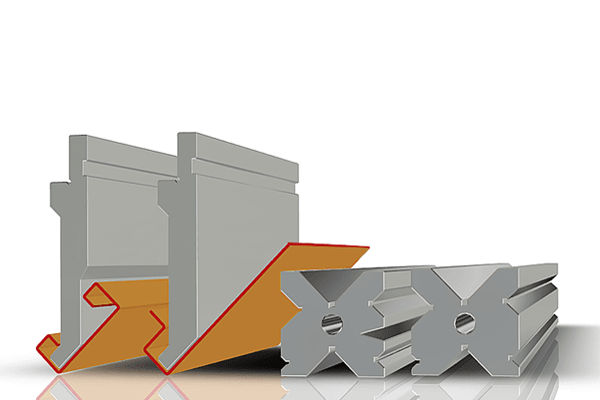

Punches & Dies

The Hydraulic Press Brake punches and dies will be one of the most important topics we discuss before you place the order. Any bending shape will be completed by a suitable set of punch and die. We can provide appropriate toolings according to different bending requirements of customers.

More Details of Hydraulic Press Brake

Hydraulic Press Brake Technical Parameter

| Model | Bending Pressure (KN) | Bendling Length (mm) | Uprights Distance (mm) | Throat Depth (mm) | Slider Stroke (mm) | Max. Opening Height (mm) | Y-axis Downward Speed (mm/sec) | Y-axis Back Stroke Speed (mm/sec) | Max. X-axis Distance (mm) | Main Motor (KW) |

|---|---|---|---|---|---|---|---|---|---|---|

| 40T/1600 | 400 | 1600 | 950 | 230 | 100 | 320 | 80 | 70 | 300 | 3 |

| 40T/2500 | 400 | 2500 | 1850 | 230 | 100 | 320 | 80 | 70 | 600 | 5.5 |

| 63T/2500 | 630 | 2500 | 1900 | 250 | 100 | 320 | 80 | 70 | 600 | 5.5 |

| 63T/3200 | 630 | 3200 | 2560 | 250 | 100 | 320 | 80 | 70 | 600 | 5.5 |

| 80T/2500 | 800 | 2500 | 1990 | 300 | 100 | 320 | 80 | 70 | 600 | 7.5 |

| 80T/3200 | 800 | 3200 | 2560 | 320 | 100 | 350 | 80 | 70 | 600 | 7.5 |

| 80T/4000 | 800 | 4000 | 3200 | 320 | 100 | 350 | 80 | 70 | 600 | 7.5 |

| 100T/2500 | 1000 | 2500 | 1990 | 320 | 120 | 350 | 80 | 70 | 600 | 7.5 |

| 100T/3200 | 1000 | 3200 | 2600 | 320 | 150 | 400 | 80 | 70 | 600 | 7.5 |

| 100T/4000 | 1000 | 4000 | 3200 | 320 | 150 | 400 | 90 | 82 | 600 | 7.5 |

| 125T/2500 | 1250 | 2500 | 1990 | 320 | 150 | 400 | 90 | 82 | 600 | 11 |

| 125T/3200 | 1250 | 3200 | 2600 | 320 | 150 | 400 | 90 | 82 | 600 | 11 |

| 125T/4000 | 1250 | 4000 | 3200 | 320 | 150 | 400 | 90 | 82 | 600 | 11 |

| 160T/2500 | 1600 | 2500 | 1990 | 320 | 200 | 460 | 90 | 86 | 600 | 11 |

| 160T/3200 | 1600 | 3200 | 2580 | 320 | 200 | 460 | 90 | 86 | 600 | 11 |

| 160T/4000 | 1600 | 4000 | 2900 | 320 | 200 | 460 | 90 | 86 | 600 | 11 |

| 160T/5000 | 1600 | 5000 | 3900 | 320 | 200 | 460 | 90 | 86 | 600 | 11 |

| 160T/6000 | 1600 | 6000 | 4900 | 320 | 200 | 460 | 90 | 86 | 600 | 11 |

| 200T/2500 | 2000 | 3200 | 1990 | 320 | 200 | 460 | 90 | 86 | 600 | 11 |

| 200T/3200 | 2000 | 3200 | 2480 | 320 | 200 | 460 | 90 | 86 | 600 | 11 |

| 200T/4000 | 2000 | 4000 | 2900 | 320 | 200 | 460 | 90 | 86 | 600 | 11 |

| 200T/5000 | 2000 | 5000 | 3900 | 320 | 200 | 460 | 90 | 86 | 600 | 11 |

| 200T/6000 | 2000 | 6000 | 4900 | 320 | 200 | 460 | 90 | 86 | 600 | 11 |

| 250T/3200 | 2500 | 3200 | 2450 | 400 | 250 | 590 | 90 | 86 | 600 | 18.5 |

| 250T/4000 | 2500 | 4000 | 2900 | 400 | 250 | 590 | 90 | 86 | 600 | 18.5 |

| 250T/5000 | 2500 | 5000 | 3900 | 400 | 250 | 590 | 90 | 86 | 600 | 18.5 |

| 250T/6000 | 2500 | 6000 | 4900 | 400 | 250 | 590 | 90 | 86 | 600 | 18.5 |

| 300T/3200 | 3000 | 3200 | 2450 | 400 | 250 | 590 | 90 | 86 | 600 | 22 |

| 300T/4000 | 3000 | 4000 | 2900 | 400 | 250 | 590 | 90 | 86 | 600 | 22 |

| 300T/5000 | 3000 | 5000 | 3900 | 400 | 250 | 590 | 90 | 86 | 600 | 22 |

| 300T/6000 | 3000 | 6000 | 4900 | 400 | 250 | 590 | 90 | 86 | 600 | 22 |

| 400T/3200 | 4000 | 3200 | 2400 | 400 | 250 | 590 | 90 | 86 | 600 | 30 |

| 400T/4000 | 4000 | 4000 | 2900 | 400 | 250 | 590 | 90 | 86 | 600 | 30 |

| 400T/5000 | 4000 | 5000 | 3900 | 400 | 250 | 590 | 90 | 86 | 600 | 30 |

| 400T/6000 | 4000 | 6000 | 4900 | 400 | 250 | 590 | 90 | 86 | 600 | 30 |

| 500T/4000 | 5000 | 4000 | 2900 | 400 | 250 | 590 | 90 | 86 | 600 | 45 |

| 500T/5000 | 5000 | 5000 | 3900 | 400 | 250 | 590 | 90 | 86 | 600 | 45 |

| 500T/6000 | 5000 | 6000 | 4900 | 400 | 320 | 590 | 90 | 86 | 600 | 45 |

| 600T/4000 | 6000 | 4000 | 2900 | 400 | 320 | 590 | 90 | 86 | 600 | 55 |

| 600T/5000 | 6000 | 5000 | 3900 | 400 | 320 | 590 | 90 | 86 | 600 | 55 |

| 600T/6000 | 6000 | 6000 | 4900 | 400 | 320 | 590 | 90 | 86 | 600 | 55 |

| 600T/7000 | 6000 | 7000 | 5900 | 400 | 320 | 590 | 90 | 86 | 600 | 55 |

| 600T/8000 | 6000 | 8000 | 6900 | 400 | 320 | 590 | 90 | 86 | 600 | 55 |

Reviewed by 11 users

Хорошая машина, я использовал ее очень хорошо