Laser cutting machines have transformed the manufacturing sector by allowing for highly precise cuts on a range of materials. However, to achieve consistent, accurate results, it’s essential to understand the concept of laser cutting machine tolerance. This refers to the permissible variation from the desired measurement, which can be either above or below the target. It serves as a key indicator of the machine’s precision and its ability to produce accurate parts.

Introduction

Tolerance defines the acceptable limits of variation in the dimensions and geometry of a cut piece, ensuring it fits the purpose for which it is designed.

Importance of Tolerance in Manufacturing

Tolerance is paramount in manufacturing as it directly affects product quality and fitment. Precise tolerance levels ensure that components fit together correctly, operate efficiently, and meet stringent quality standards.

Inconsistent or poor tolerance can lead to parts that do not assemble properly, cause redundant wear and tear, and fail to meet the safety and performance requirements, significantly impacting the overall functionality of the product.

Tolerance Ranges for Industrial Laser Cutting Machines

Industrial laser cutting machines, often classified based on their laser source, such as CO2, fiber, or YAG lasers, can achieve different levels of tolerance. Typically, high-end laser cutting machines can maintain tolerances as tight as ±0.1 mm, depending on factors like material type, thickness, and machine settings.

Understanding the specific tolerance range of each machine type is crucial for selecting the right equipment for particular manufacturing needs.

Impact of Tolerance on Quality and Precision

The impact of tolerance on quality and precision is profound. Tight tolerances are indicative of superior machine capability and lead to high-precision cuts that align perfectly with design specifications.

This precision is integral to industries such as aerospace, automotive, and medical devices, where even minor deviations can lead to significant operational issues or safety hazards.

Furthermore, consistent tolerance levels contribute to minimizing material wastage, improving production efficiency, and reducing costs associated with rework and scrap.

Tolerance Levels of Different Laser Cutting Machines

| Laser Type | Tolerance Level (mm) | Key Features |

| CO2 Laser Cutting Machines | ±0.1 to ±0.5 | – High precision – Influenced by resonator type, beam quality, and focus control – Optimal conditions enhance performance |

| Fiber Laser Cutting Machines | ±0.05 | – Superior precision – Ideal for intricate patterns in electronics and medical devices – Minimal thermal distortion |

| Nd:YAG Laser Cutting Machines | ±0.02 | – Comparable precision to fiber lasers – Preferred in aerospace and defense industries – Rigorous specifications required |

Factors Affecting Laser Cutting Machine Tolerance

Machine Calibration and Maintenance

One of the primary factors affecting laser cutting tolerance is the calibration and maintenance of the machine. Regular calibration ensures that the laser beam is correctly aligned and that all components are functioning optimally.

Maintenance routines, such as cleaning the lenses and mirrors, checking the alignment of the laser beam, and ensuring that the motion systems are free from wear and tear, are essential for maintaining high precision.

Example: Improper calibration can result in the laser beam being slightly off-center, which may cause the cuts to be uneven or the kerf (cut width) to vary across the material. For instance, if the laser beam is misaligned by even a fraction of a millimeter, the resulting cuts could be outside the specified tolerance, leading to parts that do not fit together correctly.

Calibration Steps:

- Laser Beam Alignment: Ensure the laser beam is centered and perpendicular to the cutting surface.

- Optics Cleaning: Regularly clean the lenses and mirrors to prevent any debris from distorting the beam.

- Motion System Check: Inspect and lubricate the motion systems to ensure smooth and precise movements.

- Software Updates: Keep the machine’s software up to date to benefit from the latest improvements and features.

Material Type and Thickness

The type and thickness of the material being cut can significantly impact the tolerance. Different materials react differently to laser cutting due to their varying thermal properties, reflectivity, and melting points.

Types of Materials

- Metals: Stainless steel, aluminum, and titanium each have unique properties that affect how they are cut. For example, stainless steel requires higher laser power and slower speeds compared to aluminum.

- Non-metals: Plastics, wood, and composites also behave differently under laser cutting. Plastics may melt or burn if the laser power is too high, while wood could char.

Impact of Thickness

Thicker materials introduce more variability in the cut due to increased heat-affected zones, making it challenging to maintain tight tolerances. For instance, cutting a 10mm thick stainless steel plate requires careful control of laser power and speed to avoid excessive heat buildup and warping.

Example: Cutting a 5mm thick aluminum sheet with a high-power laser may result in a wider kerf and more thermal distortion compared to cutting a 1mm thick sheet. This is primarily due to the need for higher power settings and slower speeds required for thicker materials, which contribute to greater heat accumulation and wider cuts.

Laser Power and Beam Quality

The power of the laser and the quality of the laser beam are critical factors in determining the tolerance of the cut.

Laser Power

Higher laser power can cut through thicker materials but may also introduce more thermal distortion, affecting the precision of the cut. Conversely, lower power may not penetrate thicker materials effectively, resulting in incomplete cuts.

Example: A study on laser cutting of stainless steel found that increasing laser power from 1500W to 3000W improved cutting speed but also increased the heat-affected zone, requiring adjustments in speed and focus to maintain precision.

Beam Quality

Beam quality, often quantified by the beam parameter product (BPP), influences the focus and intensity of the laser. A high-quality beam with a low BPP can achieve finer cuts with tighter tolerances.

Technical Insight: According to ISO 11145, the beam parameter product (BPP) is defined as the product of the beam radius at its narrowest point and the beam divergence angle. Lower BPP values indicate better beam quality, leading to more precise cuts.

Speed and Feed Rate Settings

The speed at which the laser head moves and the rate at which material is fed into the cutting path have a direct impact on tolerance.

Example: Cutting at higher speeds can reduce the heat input and minimize thermal distortion, but it may also compromise precision if not properly controlled. Conversely, slower cutting speeds can improve precision but increase the risk of excessive heat buildup, leading to warping and a wider kerf.

Optimal Settings:

- High Speed: Suitable for thinner materials to reduce heat impact.

- Low Speed: Necessary for thicker materials to ensure clean cuts without excessive thermal distortion.

Environmental Factors

The surrounding environment plays a surprisingly significant role in the tolerance levels achievable by laser cutting machines. Factors such as temperature, humidity, and airborne particulates can affect machine components and laser functioning.

Example: Temperature fluctuations can cause machine components to expand or contract, leading to misalignments and variations in the cut. High humidity levels can affect the performance of the laser optics and the material properties, introducing additional variability.

Control Measures:

- Maintain a controlled environment with stable temperature and humidity levels.

- Use climate control systems in the cutting area to minimize environmental impact.

Measuring and Testing Tolerance in Laser Cutting

Common Tools and Techniques for Measuring Tolerance

1. Calipers and Micrometers

Vernier Calipers

Vernier calipers are precision instruments used to measure the dimensions of laser-cut parts with high accuracy. They can measure internal and external dimensions and depths, providing a quick and reliable means of checking tolerances.

Accuracy

- 50 Division Vernier Caliper: Accuracy is 0.02 mm

- 20 Division Vernier Caliper: Accuracy is 0.05 mm

- 10 Division Vernier Caliper: Accuracy is 0.1 mm

Example: Measuring the thickness of a laser-cut metal sheet to within 0.01 mm to ensure it meets the specified tolerance.

Micrometers

Micrometers offer even greater precision than vernier calipers, capable of measuring dimensions with an accuracy of up to 0.001 mm. They are particularly useful for measuring small features and thin materials where high precision is required.

- Example: In the aerospace industry, micrometers measure the thickness of turbine blades, ensuring they meet the tight tolerances required for safe and efficient operation.

2. Coordinate Measuring Machines (CMMs)

Coordinate Measuring Machines (CMMs) are advanced tools used to measure the geometry of an object by sensing discrete points on its surface with a probe(e.g., touch-trigger, scanning) .

CMMs provide highly accurate three-dimensional measurements and are especially valuable for complex geometries and critical tolerance parts. These machines often have an accuracy in the range of ±0.005 mm to ±0.001 mm.

3. Optical Comparators

Optical comparators (also known as profile projectors) use the principles of optics to compare the contour of a manufactured part against its design specifications.

By projecting a magnified image of the part onto a screen, deviations from the desired geometry can be visually inspected and measured. This method is highly effective for profile and surface measurements.

Regular Testing and Quality Control

Benefits of Regular Testing

- Consistency: Ensures each part produced meets the specified tolerances, resulting in consistent quality across batches.

- Defect Reduction: Identifies deviations early, reducing defects and rework, saving time and materials.

- Compliance: Ensures parts comply with industry standards and customer specifications, reducing the risk of non-compliance issues.

Quality Control Methods

- Statistical Process Control (SPC): Monitoring and controlling the production process using statistical methods. By tracking key parameters, manufacturers can identify trends and variations, allowing for timely corrections.

- First Article Inspection (FAI): Inspecting the first part produced in a batch to ensure it meets the specified tolerances. This helps verify the setup and parameters before full-scale production.

- In-Process Inspection: Checking parts at different stages during production. This helps identify deviations early and allows for timely corrections.

- Post-process inspection: This involves measuring parts after the cutting process using the tools mentioned earlier to validate conformance to tolerance specifications.

Measuring Tolerance in Different Materials

1. Metal Materials

Metal parts are typically measured using a combination of mechanical gauges (like micrometers) and CMMs. Due to the reflective nature of metals and their susceptibility to burrs and edges, precise calibration and surface preparation are critical for accurate measurements.

Laser micrometers, which use a laser beam to measure distance, can also be particularly effective for thin metal sheets and tubes.

2. Non-Metal Materials

For plastics, woods, and other non-metal materials, optical measuring techniques such as laser scanners and coordinate projectors are often employed.

These materials can deform under pressure, so non-contact measurement tools ensure that their true dimensions are captured without compromising their integrity.

Improving Laser Cutting Machine Tolerance

Enhancing the tolerance of laser cutting machines is essential for achieving superior precision and consistent product quality.

This section explores best practices and strategies that can be implemented to improve the tolerance capabilities of laser cutting machines, encompassing aspects of machine setup, operator training, and technological advancements.

Best Practices for Machine Setup and Calibration

Proper machine setup and calibration are fundamental steps in achieving tight tolerances in laser cutting. Here are some best practices to follow:

Initial Setup

- Alignment: Ensure perfect alignment of the laser beam with the cutting head. Misalignment can cause uneven cuts and deviations from the desired tolerance. For example, a company improved its alignment accuracy by using a laser alignment tool, which resulted in a 20% improvement in cut quality.

- Focus Adjustment: Accurate focus adjustment is crucial. The focal point of the laser beam should be precisely set according to the material thickness and type to achieve clean cuts with minimal kerf width. Use tools like a focus gauge to ensure precision.

- Beam Quality: Regularly check the beam quality using diagnostic tools to ensure it maintains a consistent profile and intensity. High beam quality is essential for precise cuts.

Routine Calibration

Proper calibration is essential for maintaining high tolerance levels. Here are specific calibration steps:

- Laser Power Calibration: Periodically calibrate the laser power output to ensure it matches the settings on the control panel, maintaining consistent cutting performance.

- Motion System Calibration: Calibrate the motion systems (e.g., X, Y, and Z axes) for accurate positioning and movement. Deviations can lead to inaccuracies in the cut dimensions.

- Optics Maintenance: Clean and replace lenses and mirrors as needed to maintain optimal beam transmission and focus. Dirty or damaged optics can degrade beam quality and affect tolerance.

In addition to regular calibration, proactive maintenance plays a crucial role in ensuring high tolerance.

Training and Skill Development for Operators

Well-trained operators are critical to achieving and maintaining high tolerance levels in laser cutting. Here are some strategies for effective training and skill development:

Comprehensive Training Programs

- Initial Training: Provide comprehensive initial training for new operators, covering machine operation, calibration procedures, maintenance routines, and safety protocols.

- Advanced Training: Offer advanced training modules focused on specific aspects such as optimizing cutting parameters for different materials, troubleshooting common issues, and using advanced software features.

Continuous Skill Development

- Regular Workshops: Conduct regular workshops and training sessions to keep operators updated with the latest technologies, techniques, and best practices in laser cutting.

- Certifications: Encourage operators to pursue relevant certifications that validate their skills and knowledge in operating laser cutting machines.

Hands-On Experience

- Practical Sessions: Facilitate hands-on training sessions where operators can practice setting up, calibrating, and maintaining the machines. Real-world experience is invaluable in honing their skills.

- Mentorship Programs: Implement mentorship programs where experienced operators guide and support less experienced colleagues, fostering knowledge sharing and skill enhancement.

Advanced Technologies and Software Solutions

1. Automated Calibration Systems

Incorporating automated calibration systems can greatly enhance the precision of laser cutting machines. These systems use sensors and feedback loops to constantly monitor and adjust the laser beam and machine components, ensuring optimal alignment and focus without manual intervention. This automation reduces human error and improves consistency in achieving desired tolerance levels.

2. High-Resolution Imaging and Feedback

Advanced imaging technologies, such as high-resolution cameras and laser scanners, can provide real-time feedback on the cutting process.

These systems detect deviations from the programmed paths and make on-the-fly adjustments to maintain tight tolerances. Implementing such technologies enhances the capability to produce intricate and precise cuts consistently.

3. Intelligent Software Solutions

Laser cutting software has evolved to include sophisticated algorithms that optimize cutting paths, adjust for material inconsistencies, and predict potential deviations. Integrating intelligent software solutions that support adaptive learning and process simulation can aid in identifying and mitigating tolerance issues before they affect production.

Challenges and Solutions in Achieving Optimal Tolerance

Challenges in Achieving Optimal Tolerance

Thermal Distortion

Thermal Distortion is one of the most prevalent issues affecting laser cutting tolerance. The heat generated by the laser can cause the material to expand and contract, leading to warping or changes in dimensions.

- Example: When cutting thick metal sheets, the localized heat input can cause the edges to expand and contract unevenly, leading to warping and deviations from specified tolerances. For instance, a 10mm thick steel sheet might warp by 0.2mm at the edges.

Solution:

- Heat Management: Utilize techniques such as pulsed laser cutting, where the laser is operated in short bursts, reducing the overall heat input and minimizing thermal distortion.

- Cooling Systems: Implement effective cooling systems to dissipate heat quickly and maintain the material’s structural integrity.

Kerf Variation

Kerf Variation refers to inconsistencies in the width of the cut, which can affect the fit and function of the parts.

- Example: Variations in kerf width can lead to parts that do not fit together as intended, especially in applications requiring tight tolerances like aerospace components.

Solution:

- Consistent Parameters: Ensure consistent laser power, speed, and focus settings throughout the cutting process to maintain uniform kerf width.

- Beam Quality Monitoring: Regularly check and adjust the laser beam quality to ensure it remains consistent, minimizing kerf variation.

Material Inconsistencies

Different batches of materials can have varying properties, such as thickness and composition, leading to challenges in maintaining consistent tolerance.

- Example: A batch of stainless steel with slight variations in thickness can result in cuts that deviate from the specified tolerances.

Solution:

- Material Certification: Source materials from certified suppliers with strict quality control measures to ensure consistency.

- Adaptive Control Systems: Implement adaptive control systems that adjust cutting parameters in real-time based on material properties, ensuring consistent results.

Machine Wear and Tear

Over time, laser cutting machines can experience wear and tear, affecting their precision and ability to maintain tight tolerances.

- Example: Worn-out motion systems or misaligned optics can lead to inaccuracies in the cutting process.

Solution:

- Preventive Maintenance: Implement a structured preventive maintenance schedule that includes daily, weekly, and monthly inspections. Regularly check for worn-out motion systems, misaligned optics, and laser source deterioration to prevent any decline in cutting quality.

- Component Replacement: Replace worn or damaged components promptly to maintain the machine’s performance and precision.

Environmental Factors

Environmental conditions such as temperature fluctuations, humidity, and air quality can impact laser cutting tolerance.

- Example: High humidity can affect the laser optics and the material being cut, leading to variations in the cut dimensions.

Solution:

- Controlled Environment: Maintain a controlled environment with stable temperature and humidity levels to minimize their impact on the cutting process.

- Air Filtration Systems: Use air filtration systems to keep the cutting area free from dust and contaminants that could affect the laser optics and material.

Solutions for Overcoming Tolerance Challenges

1. Routine Maintenance and Upgrades

Regular maintenance schedules should be strictly followed to mitigate the effects of wear and tear. This includes lubricating moving parts, replacing worn components, and regularly cleaning and aligning optical elements.

Upgrading hardware and software can also enhance machine performance and tolerance capabilities. Emerging technologies, such as improved beam delivery systems, can provide more stable and precise cutting operations.

2. Material Quality Control

Implementing rigorous quality control practices for incoming materials can help minimize variability. This includes pre-inspection of material batches for consistency in thickness, density, and composition.

Standardizing material suppliers and batch tracking can also reduce variability and provide more predictable cutting results.

3. Advanced Cooling Systems

To address thermal effects, integrating advanced cooling systems can help manage and dissipate heat more effectively. Water-cooled laser heads, for example, can reduce thermal distortion by maintaining a stable temperature during cutting.

Additionally, implementing real-time thermal monitoring and adaptive control systems can dynamically adjust cutting parameters to compensate for heat buildup.

4. Environmental Controls

Optimizing the working environment is crucial for maintaining consistent laser cutting performance. This involves climate control solutions to regulate temperature and humidity, and air filtration systems to keep the workspace free from dust and particulates.

Creating a stable and clean environment can significantly enhance the precision and reliability of the cutting process.

5. Process Optimization and Automation

Implementing process optimization technologies such as predictive maintenance and automated calibration systems can significantly improve tolerance maintenance.

These technologies utilize sensors and algorithms to predict potential issues and automate adjustments, ensuring consistent machine performance. Process automation also minimizes human error and enhances repeatability, leading to better tolerance adherence.

FAQs

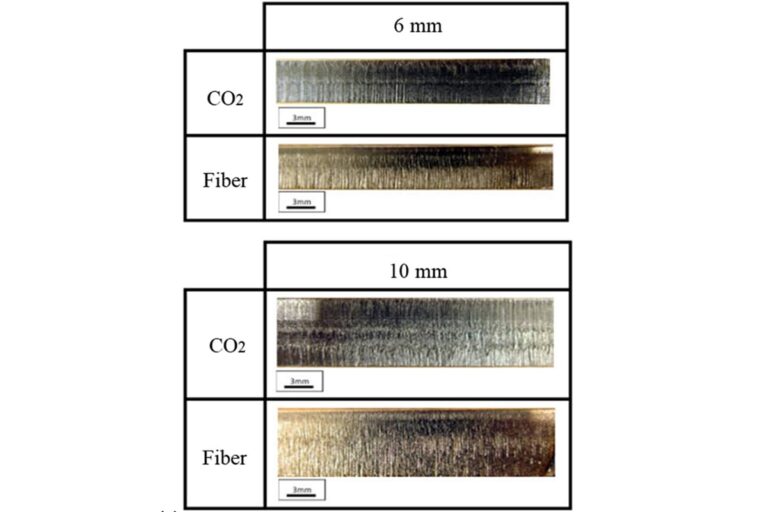

What are the differences in tolerance between CO2 and fiber laser cutting machines?

CO2 and fiber laser cutting machines differ fundamentally in their technology and the materials they effectively process, which impacts their achievable tolerances.

CO2 lasers are versatile, capable of cutting a wide range of materials including metals, plastics, and organics, but their beam properties typically result in broader tolerance levels.

In contrast, fiber lasers offer superior precision and are particularly advantageous for cutting metals due to their higher power density and effective absorption by metal surfaces.

This results in tighter tolerance levels with minimal thermal distortion, making fiber lasers more suitable for applications requiring stringent precision.

Are there specific standards for laser cutting tolerance in the automotive industry?

Yes, the automotive industry adheres to specific standards for laser cutting tolerance to ensure the quality, safety, and interoperability of components.

These standards often align with broader international quality control standards like ISO 9001 for quality management systems and IATF 16949, specifically for automotive quality management.

Tolerances in the automotive sector are tightly controlled to ensure that parts fit precisely within complex assemblies, contributing to the overall performance and safety of the vehicle.

Manufacturers often implement rigorous quality control measures, including regular inspection and testing, to ensure compliance with these standards.

What advanced technologies can help improve laser cutting tolerance?

Several advanced technologies have been developed to enhance laser cutting tolerance. Automated calibration systems utilize sensors and feedback loops to continuously monitor and adjust machine parameters, ensuring precise alignment and focus.

High-resolution imaging and laser feedback systems provide real-time monitoring during the cutting process, allowing for immediate corrections to maintain tight tolerances.

Intelligent software solutions further optimize cutting parameters, compensating for material inconsistencies and environmental variations, and supporting predictive maintenance to prevent deviations over time.

Integrating these technologies into laser cutting processes leads to higher precision, improved efficiency, and reduced error rates.