In recent years, the demand for a metal laser cutting machine for home use has surged among DIY enthusiasts and small business owners. These innovative devices, once reserved for industrial applications, are now accessible to hobbyists who want to bring precision and versatility into their personal workshops. Whether you're looking to create custom metal signs, intricate jewelry, or unique home decor, a metal laser cutting machine for home can transform your creative ideas into reality with unparalleled accuracy and ease. In this article, we will explore the benefits of owning such a machine, how to choose the right one for your needs, and the exciting projects you can undertake right from the comfort of your home.

What Is A Home Use Laser Cutter

In recent years, the use of metal laser cutting machines for home has become increasingly popular among hobbyists, DIY enthusiasts, and small business owners. A metal laser cutting machine is a device that uses a focused laser beam to cut, engrave, and shape metal materials with high precision and speed. These machines, once primarily used in industrial settings, are now accessible and affordable for personal use, allowing users to undertake a wide range of projects from the comfort of their own homes.

Why Home Use Laser Cutter Become Popular

The growing trend of using metal laser cutting machines at home can be attributed to several factors. Advances in technology have made these machines more compact, user-friendly, and cost-effective. Additionally, the rise of maker culture and the increasing popularity of DIY projects have spurred interest in tools that can enhance creativity and craftsmanship. As a result, more people are investing in metal laser cutting machines to explore new hobbies, create unique products, and even start small businesses.

Owning a metal laser cutting machine at home offers numerous benefits and applications. These machines provide unparalleled precision, allowing users to create intricate designs and detailed engravings. They are versatile, capable of cutting through various metals, including stainless steel, aluminum, and brass, as well as non-metal materials like wood and acrylic. This versatility opens up a wide array of possibilities for projects such as custom jewelry, decorative items, signage, and functional parts. Furthermore, having a metal laser cutting machine at home saves time and money by eliminating the need to outsource cutting and engraving tasks, giving users complete control over their creative process.

Benefits of Owning a Metal Laser Cutting Machine at Home

Having a cutting machine at home has many benefits - it offers versatility, precision, time-savings, and is a great way to unleash creativity. It can be used for crafting, making party invitations, decorations, promotional materials, or even for DIY home improvement projects like creating stencils, making custom labels, or designing wall art. It is also a great educational tool, as it can be used to teach various skills like design, math, and fine motor skills. In addition, it can save money in the long run as it allows you to create your own cards, decorations, and personalized gifts instead of buying them. Finally, it can provide a creative outlet and be a satisfying and enjoyable hobby.

Common Projects You Can Create with a Metal Laser Cutting Machine For Home

By utilizing a laser cutter and engraver, you can make beautiful and functional items that can enhance the look and feel of any home. You can also customize your products with different designs, colors, and personalization options to suit your customers’ preferences and needs.

1. Custom Family Name Sign

This customizable laser-cut wooden sign project is a top-seller on Etsy, making it a profitable and popular home decor item to add to your product lineup. The large cut-out letters, made from high-quality birch plywood or MDF, are a trendy addition to any living space.

With easy customization options, you can offer your customers the ability to personalize the sign with their family name or other text, making it a hot-selling item for housewarming or wedding gifts.

The precision and crispness of the laser-cut design make this sign a premium product that stands out from the crowd, and its versatility allows it to fit into a variety of home decor styles. With high customer reviews and ratings, you can confidently add this laser-cut home decor item to your offerings and watch your sales soar.

2. 3D Wooden World Map Art

This wooden world map wall art is a stunning product project that will impress your customers and boost your sales. This laser cutting project is made of high-quality plywood and laser cut and engraved for precision and detail. It comes with push pins that allow your customers to mark their travels and plan their next journeys.

This wooden world map wall art is a versatile product that can fit into any interior style, from rustic to modern. It is a great gift idea for travelers, adventurers, or anyone who loves to explore the world. You can offer your customers different types and sizes of maps, as well as add-ons such as country names, flags, or LED lights.

3. Decorative Acrylic Wall Clock

This laser cut cat silhouette wall clock is a cute and colorful product that will make your customers smile. This clock is laser cut from two layers of acrylic(black matt and yellow gloss), creating a strong contrast that is easy to fit on any wall. It features a silent quartz movement that does not tick, making it ideal for bedrooms or offices.

This laser cutting project is a fun and unique product that can appeal to cat lovers, kids, or anyone who likes simple designs. You can offer your customers different colors and sizes of clocks, as well as different shapes of silhouettes.

4. Wall-Mounted Key Holder

This laser cutting key and leashes holder is another one among the simple and beginner laser cutter projects. With your creativity and the possibilities of laser cutting, you can create endless designs and styles to meet the preferences of different customers.

The practical design is perfect for keeping keys and leashes organized and easily accessible. This product is not only a great item to sell in your online store, but it can also be offered as a custom-made product to your local customers.

5. Wooden Animal Planter

If you are looking for a fun and unique home decor item to add to your product lineup, look no further than this laser cut corgi planter stand project.

It is made from high-quality plywood and features a cute corgi shape that you can customize with your choice of color and name, making it a perfect gift idea for any dog lover or plant lover. The laser-cut design ensures a crisp and detailed finish that will impress your customers. With high customer reviews and ratings on Etsy, you can add this laser-cut home decor item to your product lineup and watch your sales soar.

How To Set Up Home Laser Cutting Machine

Setting up a metal laser cutting machine at home requires careful planning and execution to ensure safety, efficiency, and optimal performance. Here’s a comprehensive guide to help you through the process.

Step 1: Choose the Right Location

- Workspace Requirements:

- Space: Ensure you have enough space to accommodate the machine and allow for easy access around it. The workspace should be well-ventilated.

- Surface: Use a stable, flat surface to place the machine. A sturdy workbench or table is ideal.

- Environment: The area should be dry and free from flammable materials. Avoid placing the machine near heat sources or direct sunlight.

- Electrical Supply:

- Check the machine's power requirements and ensure your workspace has the necessary electrical outlets.

- Consider using a surge protector to safeguard the machine from power fluctuations.

Step 2: Unbox and Inspect the Machine

- Unboxing:

- Carefully unbox the machine and inspect all components for any damage during shipping.

- Verify that all parts and accessories are included as per the manufacturer’s checklist.

- Components:

- Familiarize yourself with the main components: laser tube, laser head, cooling system, control panel, and exhaust system.

Step 3: Assemble the Machine

- Follow the Manual:

- Refer to the manufacturer’s installation manual for specific assembly instructions.

- Attach the laser tube, align the mirrors, and install the laser head as directed.

- Install the Cooling System:

- If your machine requires a cooling system (e.g., water chiller), set it up according to the instructions. Ensure proper connections and check for leaks.

- Connect the Exhaust System:

- Proper ventilation is crucial to remove fumes and smoke. Connect the exhaust system to a suitable outlet, such as a window or a dedicated ventilation duct.

Step 4: Install and Configure Software

- Software Installation:

- Install the recommended software on your computer. This might include design software and machine control software.

- Ensure your computer meets the software’s system requirements.

- Machine Configuration:

- Connect the laser cutter to your computer using the appropriate cables (USB, Ethernet, etc.).

- Configure the software settings to match your machine’s specifications. Calibrate the machine as per the instructions to ensure accuracy.

Step 5: Perform Initial Tests

- Power On and Test:

- Turn on the machine and run initial tests to check functionality.

- Test the laser movement, focus, and alignment using scrap materials.

- Adjust Settings:

- Fine-tune the settings based on the test results. Adjust the laser power, speed, and focus as needed.

Step 6: Safety Tips and Best Practices

- Safety Gear:

- Always wear appropriate safety gear, including laser safety glasses designed for the specific wavelength of your laser.

- Consider wearing gloves and protective clothing if handling sharp or hot materials.

- Ventilation:

- Ensure the exhaust system is functioning properly to avoid inhaling harmful fumes.

- Keep the workspace well-ventilated at all times.

- Emergency Procedures:

- Keep a fire extinguisher nearby and familiarize yourself with its operation.

- Know the location of emergency stop buttons on the machine.

- Routine Maintenance:

- Clean the machine regularly to remove dust, debris, and residue.

- Check and replace consumables, such as laser tubes and lenses, as needed.

- Inspect and maintain the cooling system to prevent overheating.

- Operational Best Practices:

- Do not leave the machine unattended while it is operating.

- Use appropriate settings for different materials to prevent damage to the machine and materials.

- Keep the work area clean and organized to avoid accidents.

Setting up your home metal laser cutting machine involves careful preparation, proper installation, and adherence to safety protocols. By following this step-by-step guide, you can ensure a smooth setup process and enjoy the full potential of your laser cutting machine safely and efficiently. Remember to perform regular maintenance and stay informed about best practices to keep your machine running optimally.

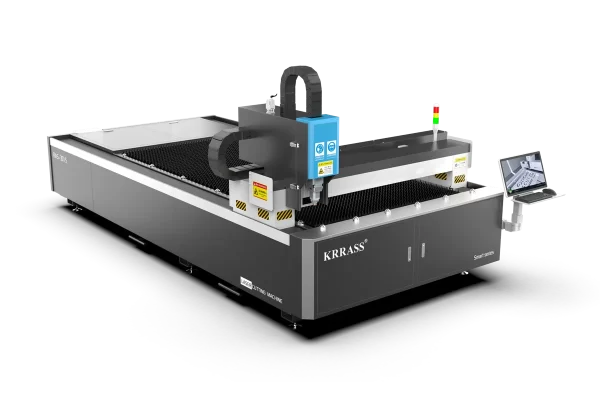

Top 10 Metal Laser Cutting Machines for Home Use in 2024

The popularity of metal laser cutting machines for home use has skyrocketed, offering hobbyists, DIY enthusiasts, and small business owners the ability to create precise and intricate designs from the comfort of their own homes. Here, we present the top 10 metal laser cutting machines for home use in 2024, considering factors such as performance, ease of use, affordability, and versatility.

1. OMTech K40 CO2 Laser Engraver

- Power: 40W CO2 laser

- Cutting Area: 300 x 200 mm

- Price: $400 - $600

- Pros: Affordable, compact, easy to use

- Cons: Limited to thin metals, requires regular maintenance

2. Glowforge Plus

- Power: 45W CO2 laser

- Cutting Area: 515 x 455 mm

- Price: $3,995

- Pros: High-quality build, cloud-based software, versatile

- Cons: Expensive, limited to thin metals

3. Ortur Laser Master 2 Pro

- Power: 20W laser

- Cutting Area: 400 x 400 mm

- Price: $500 - $700

- Pros: Affordable, good for engraving coated metals, beginner-friendly

- Cons: Not suitable for cutting thick metals, lower power

4. BOSS Laser LS-1416

- Power: 65W CO2 laser

- Cutting Area: 400 x 300 mm

- Price: $4,997

- Pros: Robust build, excellent support, suitable for small business

- Cons: High cost, large footprint

5. Dremel Digilab LC40

- Power: 40W CO2 laser

- Cutting Area: 610 x 406 mm

- Price: $5,999

- Pros: Reliable performance, high-quality components, user-friendly software

- Cons: Expensive, limited metal cutting capability

6. Snapmaker 2.0 A350T

- Power: 10W laser module

- Cutting Area: 320 x 350 mm

- Price: $1,799

- Pros: Modular design, multifunctional (3D printing, CNC, laser cutting), compact

- Cons: Lower laser power, not specialized for metal cutting

7. FLUX Beamo

- Power: 30W CO2 laser

- Cutting Area: 300 x 210 mm

- Price: $1,995

- Pros: Compact, easy to use, versatile

- Cons: Lower power, limited metal cutting

8. Ten-High 50W CO2 Laser Cutting Machine

- Power: 50W CO2 laser

- Cutting Area: 400 x 300 mm

- Price: $1,500 - $2,000

- Pros: High precision, suitable for hobbyists and small businesses, reliable

- Cons: Larger footprint, requires regular maintenance

9. FSL Muse Core

- Power: 40W CO2 laser

- Cutting Area: 508 x 305 mm

- Price: $3,500

- Pros: High-resolution camera, advanced software, user-friendly

- Cons: Expensive, limited to thin metals

10. Atomstack A5 Pro

- Power: 40W laser

- Cutting Area: 410 x 400 mm

- Price: $300 - $400

- Pros: Affordable, easy to assemble, good for beginners

- Cons: Lower power, not suitable for cutting thick metals

Comparison of Pros and Cons

| OMTech K40 | Affordable, compact, easy to use | Limited to thin metals, regular maintenance |

| Glowforge Plus | High-quality build, versatile | Expensive, limited to thin metals |

| Ortur Laser Master 2 Pro | Affordable, beginner-friendly | Not suitable for thick metals, lower power |

| BOSS Laser LS-1416 | Robust, excellent support, business suitable | High cost, large footprint |

| Dremel Digilab LC40 | Reliable, high-quality, user-friendly | Expensive, limited metal cutting capability |

| Snapmaker 2.0 A350T | Modular, multifunctional, compact | Lower laser power, not specialized for metal |

| FLUX Beamo | Compact, easy to use, versatile | Lower power, limited metal cutting |

| Ten-High 50W | High precision, reliable, versatile | Larger footprint, regular maintenance |

| FSL Muse Core | High-resolution camera, advanced software | Expensive, limited to thin metals |

| Atomstack A5 Pro | Affordable, easy to assemble, good for beginners | Lower power, not suitable for thick metals |

Choosing the right metal laser cutting machine for home use depends on your specific needs, budget, and the types of projects you plan to undertake. From affordable options like the Atomstack A5 Pro and OMTech K40 to more advanced models like the Glowforge Plus and BOSS Laser LS-1416, there's a machine to suit every requirement. Consider the pros and cons of each model to find the perfect match for your home workshop.

Software and Tools for Designing with a Home Metal Laser Cutting Machine

Designing with a home metal laser cutting machine requires the right software and tools to create and prepare your designs for cutting. Here are some software options and tools commonly used for this purpose:

1. Computer-Aided Design (CAD) Software

CAD software allows you to create precise 2D and 3D designs that can be exported to your laser cutting machine. Some popular CAD software options include:

- AutoCAD: Industry-standard CAD software known for its powerful 2D and 3D design capabilities.

- Fusion 360: A cloud-based CAD/CAM platform that integrates design, engineering, and manufacturing tools.

- SolidWorks: Widely used for mechanical design, SolidWorks offers robust features for creating detailed 3D models.

- SketchUp: User-friendly software for creating 3D models, often used by hobbyists and beginners.

2. Vector Graphic Software

Vector graphic software is essential for creating scalable designs that can be easily imported into laser cutting software. Common vector graphic software includes:

- Adobe Illustrator: Professional-grade software for creating vector graphics and illustrations.

- CorelDRAW: A versatile vector graphic editor with powerful design tools and compatibility with laser cutting machines.

- Inkscape: A free and open-source vector graphics editor suitable for beginners and professionals alike.

3. Laser Cutting Software

Laser cutting software is specifically designed to prepare your designs for cutting on a laser machine. These programs typically offer features such as:

- Importing and Editing: Import designs from CAD or vector graphic software and make any necessary adjustments.

- Nesting: Optimize material usage by arranging multiple designs on a single sheet.

- Toolpath Generation: Generate cutting paths based on your design, specifying parameters such as speed, power, and cutting order.

- Simulation: Preview the cutting process to ensure accuracy and identify any potential issues before cutting.

Some laser cutting machines come with proprietary software, while others may be compatible with third-party software. Be sure to check the compatibility of your machine with the software you choose.

4. Plugins and Extensions

Many CAD and vector graphic software offer plugins or extensions that enhance their functionality for laser cutting. These plugins may provide additional features such as:

- Direct Export: Export designs directly to your laser cutting software format.

- Parametric Design: Create customizable designs that can be adjusted based on specific parameters.

- Material Library: Access pre-configured settings for different materials and thicknesses.

With the right software and tools, you can unleash your creativity and efficiently prepare designs for laser cutting with your home metal laser cutting machine. Whether you're a beginner or an experienced designer, there are plenty of options available to suit your needs and preferences. Experiment with different software and tools to find the ones that work best for you, and enjoy the process of bringing your ideas to life with laser cutting.

CO2 vs. Fiber Laser Cutting Machines: Which Is Better For Home Use

When considering a laser cutting machine for home use, two popular types are CO2 and fiber lasers. Each has its own set of advantages and disadvantages, making them suitable for different applications. Here’s a comprehensive comparison to help you decide which type is best for your needs.

CO2 Laser Cutting Machines

1. Working Principle:

- Gas Laser: Uses a gas mixture, primarily carbon dioxide, excited by electricity to produce a laser beam.

- Wavelength: Typically around 10.6 micrometers, effective for cutting non-metals and some metals.

2. Material Compatibility:

- Non-Metals: Highly effective for cutting and engraving non-metals like wood, acrylic, glass, leather, and paper.

- Metals: Can cut thin metals (usually up to 3-6mm depending on the power), but not as efficient or precise as fiber lasers for metals.

3. Cutting Speed and Quality:

- Speed: Slower than fiber lasers, especially with thicker materials.

- Quality: Provides smooth and clean cuts for non-metals, but may produce rougher edges on metals.

4. Cost:

- Initial Investment: Generally less expensive than fiber lasers, making them more accessible for hobbyists and small businesses.

- Maintenance: Higher maintenance costs due to the need for regular replacement of mirrors and laser tubes.

5. Applications:

- Ideal for artistic projects, signage, model making, and other applications involving non-metals.

- Suitable for small-scale metal cutting projects with thinner materials.

Fiber Laser Cutting Machines

1. Working Principle:

- Solid-State Laser: Uses a solid gain medium, with the laser beam generated through a seed laser and amplified within optical fibers.

- Wavelength: Typically around 1.06 micrometers, allowing for high precision in cutting metals.

2. Material Compatibility:

- Metals: Highly effective for cutting metals such as stainless steel, aluminum, brass, and copper.

- Non-Metals: Limited effectiveness; generally not recommended for non-metals as the beam can be too intense and cause material damage.

3. Cutting Speed and Quality:

- Speed: Faster cutting speeds, especially for thin to medium-thickness metals.

- Quality: High precision and quality cuts with minimal burrs, excellent for intricate metal designs.

4. Cost:

- Initial Investment: Higher upfront cost compared to CO2 lasers, making them a larger investment.

- Maintenance: Lower maintenance costs due to fewer consumables and longer-lasting components.

5. Applications:

- Best suited for metalworking, including fabrication, automotive parts, electronics, and other industrial applications.

- Not recommended for extensive use with non-metal materials.

Pros and Cons

CO2 Lasers

Pros:

- Versatile with a wide range of non-metal materials.

- Lower initial cost, making it accessible for hobbyists and small businesses.

- Excellent for engraving and cutting non-metals with smooth, clean finishes.

Cons:

- Slower cutting speeds, especially for metals.

- Higher maintenance due to the need for replacing mirrors and tubes.

- Limited effectiveness with thicker metals.

Fiber Lasers

Pros:

- Superior cutting speed and precision for metals.

- Lower maintenance with fewer consumable parts.

- Longer lifespan and higher efficiency.

Cons:

- Higher initial cost, which may be prohibitive for some home users.

- Limited to metal cutting, with less versatility for non-metals.

- Intense beam can damage non-metal materials.

When choosing between CO2 and fiber laser cutting machines for home use, consider your primary materials and applications. CO2 lasers offer versatility and lower costs for non-metal projects, making them ideal for hobbyists and small businesses working with a variety of materials. Fiber lasers, while more expensive, provide superior performance for metal cutting, making them suitable for more specialized or industrial applications. Assess your needs, budget, and the types of projects you plan to undertake to make the best choice for your home workshop.

How to Choose the Right Metal Laser Cutting Machine for Your Home Workshop

Selecting the right metal laser cutting machine for your home workshop involves considering several key factors to ensure it meets your specific needs and fits within your budget. Here's a comprehensive guide to help you make an informed decision.

1.Power

- Laser Power: Determines the types of materials and thicknesses you can cut. Higher wattage allows for cutting thicker metals.

- Common Power Ranges:

- Low Power (20W-40W): Suitable for engraving and cutting thin metals and non-metals.

- Medium Power (40W-60W): Can handle thicker metals and more detailed work.

- High Power (60W and above): Ideal for cutting thick metals and high-speed production.

2.Size

- Cutting Area: The size of the machine’s workbed, which dictates the maximum size of the material you can work with.

- Workspace Requirements: Consider the physical size of the machine and ensure you have enough space in your workshop, including room for ventilation.

3.Budget

- Initial Cost: Prices range from a few hundred to several thousand dollars.

- Additional Costs: Include accessories, software, maintenance, and potentially higher electricity usage.

4.Material Compatibility

- Ensure the machine can handle the types of metals (e.g., stainless steel, aluminum, brass) you intend to cut.

- Consider if you need versatility for cutting non-metals as well.

5.Software Compatibility

- Check if the machine is compatible with popular design software like AutoCAD, Adobe Illustrator, or CorelDRAW.

- User-friendly software can significantly enhance your experience.

6.Safety Features

Look for machines with safety enclosures, emergency stop buttons, proper ventilation systems, and protective eyewear.

7.Maintenance

- Consider the ease of maintenance and availability of replacement parts.

- Check if the manufacturer offers good customer support and warranties.

Safety Tips for Using a Metal Laser Cutting Machine For Home

Operating a metal laser cutting machine at home requires strict adherence to safety protocols to prevent accidents and ensure a safe working environment. Here are essential safety tips to keep in mind:

1. Personal Protective Equipment (PPE)

- Laser Safety Glasses: Always wear laser safety glasses that are appropriate for the wavelength of your laser to protect your eyes from direct and reflected laser beams.

- Protective Clothing: Wear non-flammable clothing, gloves, and closed-toe shoes to protect your skin from sparks, debris, and potential laser exposure.

- Respiratory Protection: Use a mask or respirator if you are cutting materials that produce harmful fumes or particles.

2. Workspace Safety

- Ventilation: Ensure your workspace is well-ventilated to remove smoke, fumes, and particulate matter generated during cutting. Use an exhaust system to direct fumes outside.

- Fire Safety: Keep a fire extinguisher rated for electrical and chemical fires within reach. Know how to use it and conduct regular checks to ensure it is in working order.

- Clean Environment: Keep the workspace clean and free of clutter to reduce fire hazards and ensure smooth operation.

3. Machine Setup and Operation

- Proper Setup: Follow the manufacturer’s guidelines for setting up the machine, including proper alignment of the laser and mirrors, secure mounting of components, and correct installation of the cooling and exhaust systems.

- Material Safety: Know the materials you are cutting. Avoid cutting materials that release toxic fumes or can cause fires, such as PVC and certain plastics.

- Supervision: Never leave the machine unattended while it is operating. Always monitor the cutting process to respond quickly to any issues.

- Emergency Stop: Familiarize yourself with the location and operation of the emergency stop button. Use it immediately if something goes wrong.

4. Maintenance and Inspection

- Regular Maintenance: Perform regular maintenance according to the manufacturer’s schedule. This includes cleaning the laser head, checking and replacing the laser tube, and maintaining the cooling system.

- Inspection: Before each use, inspect the machine for any signs of wear, damage, or misalignment. Ensure all safety features are functioning correctly.

- Calibration: Regularly calibrate the machine to maintain cutting accuracy and prevent mishaps.

5. Electrical Safety

- Proper Wiring: Ensure that the machine is properly grounded and that all electrical connections are secure and compliant with safety standards.

- Surge Protection: Use surge protectors to protect the machine from power spikes that could damage electronic components.

- Dry Environment: Keep the machine and electrical components dry to prevent short circuits and electrical hazards.

6. Operational Best Practices

- Material Placement: Secure materials properly on the cutting bed to prevent movement during cutting, which can cause inaccuracies and accidents.

- Laser Focus: Adjust the laser focus appropriately for each material to ensure efficient cutting and minimize the risk of fire or damage.

- Cooling System: Monitor the cooling system to ensure the laser does not overheat. Replace coolant as needed and check for leaks.

7. Training and Education

- Operator Training: Ensure that anyone operating the machine has received proper training on its use, safety protocols, and emergency procedures.

- Stay Informed: Keep up to date with the latest safety guidelines and best practices for laser cutting. Regularly review the machine’s manual and any updates from the manufacturer.

Conclusion

As technology continues to advance, the functionality and performance of metal laser cutting machine for home are also improving, making the future development trends very promising. Firstly, as technology becomes more widespread and costs decrease, these devices will become more affordable, allowing more households and small businesses to access them. Secondly, the development of intelligent and automated technologies will make laser cutting machines easier to operate and maintain, enabling even beginners to use them with ease and further lowering the barrier to entry.