This article delves into the intricacies of Press Brake Forming, exploring various processes, materials, and techniques. Whether you're a seasoned professional or new to the field, this guide offers valuable insights into the world of precision metal shaping.

- What is Press Brake?

- What is Press Brake molding?

- Press Brake molding process and diversity characteristics

- Materials suitable for Press Brake molding

- Types of Press Brake molding

- Advantages and disadvantages of Press Brake molding

- What is the difference between Press Braking and Forming?

- What is the difference between rolling and forming?

1.What is Press Brake?

Press Brake, a fundamental tool in the world of metal fabrication, stands as a cornerstone technology in modern manufacturing. This versatile equipment is pivotal in shaping sheet metal into desired forms through precision bending. Utilizing a combination of force, angle, and position, a press brake manipulates metal sheets into various shapes and sizes, catering to a wide range of industrial applications.

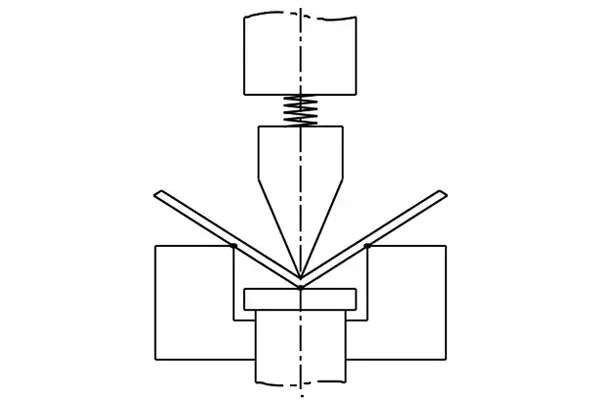

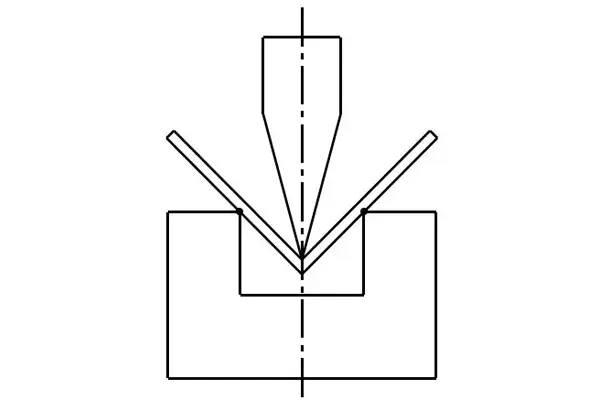

At its core, the Press Brake employs a simple yet effective mechanism: a punch and die. Metal sheets are placed between these two components. The punch, moving downwards, forces the metal sheet into the die, creating a precise bend. This process can be repeated multiple times to achieve complex multi-bend geometries. The specificity of the press brake lies in its ability to produce high-quality, repeatable bends, making it an invaluable asset in any manufacturing setup.

One of the key strengths of the Press Brake is its adaptability. Modern press brakes are equipped with CNC (Computer Numerical Control) technology, allowing for automated, highly accurate, and repeatable bends. This integration of technology not only enhances precision but also boosts efficiency, reducing manual labor and margin for error. Such advancements make press brakes an essential tool for industries requiring high levels of accuracy and consistency, like aerospace, automotive, and construction.

2.What is Press Brake Molding?

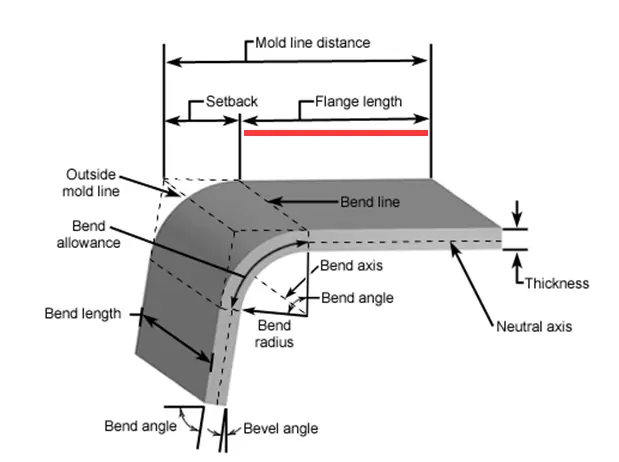

Press Brake Molding, a specialized process within the realm of metal forming, involves the strategic shaping of metal sheets using a press brake. This process goes beyond mere bending; it's about transforming a flat sheet of metal into a specific, often complex, shape with precise dimensions and angles. Press Brake Molding is pivotal in creating components that meet exacting standards required in specialized fields.

The essence of Press Brake Molding lies in its versatility and precision. Different tools and dies are used to achieve various bends and forms. These tools can be customized to create unique geometries, catering to specific project requirements. The process involves careful planning and design, often utilizing CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to pre-plan the bends and sequences required for the desired outcome.

One significant advantage of Press Brake Molding is its ability to produce small batches or even single-item orders economically. This flexibility is crucial for bespoke projects or in industries where customization is key. Moreover, with advancements in CNC technology, Press Brake Molding has become more efficient, allowing for quicker turnaround times while maintaining high precision.

3.Press Brake Molding Process and Diversity Characteristics

3.1 Press Brake Molding Process

The Press Brake Molding Process is a meticulous and multi-step procedure, ensuring the transformation of metal sheets into precise shapes and sizes. Initially, the process begins with the selection of the appropriate metal material, considering factors such as thickness, grade, and malleability. The metal sheet is then positioned on the press brake machine between the punch and die.

Once in place, the press brake operator programs the machine, usually through CNC technology, to execute specific bends at predetermined angles. This programming is a critical step as it dictates the accuracy and shape of the final product. The punch then descends and presses the metal sheet into the die, creating the bend. This action is repeated, and the sheet is manipulated until the desired shape is achieved.

After the bending process, quality checks are conducted to ensure the dimensions and angles align with the design specifications. Adjustments are made if necessary, highlighting the process's iterative nature, which is central to achieving precision.

3.2 Process Characteristics

The Process Characteristics of Press Brake Molding are diverse and multifaceted. One of the most notable features is its precision and repeatability, especially with CNC-controlled press brakes. This precision is paramount in industries where even the slightest deviation can have significant implications.

Another characteristic is the process's versatility. The press brake can handle a variety of metal types and thicknesses, and by changing the tools and dies, it can produce a wide range of shapes and sizes. This adaptability makes it suitable for multiple applications, from small custom pieces to large-scale industrial parts.

4.Materials Suitable for Press Brake Molding

The success of Press Brake Molding largely depends on selecting the right material. Each material brings unique properties to the table, influencing the molding process's effectiveness and the final product's quality. Let's explore some of the most suitable materials for Press Brake Molding.

Carbon Steel: Known for its durability and strength, carbon steel is a popular choice. It's versatile and can be used in a variety of applications, from industrial machinery to structural components. The material's resilience makes it ideal for precise bending processes.

Stainless Steel: Favored for its corrosion resistance, stainless steel is a go-to material for items exposed to harsh environments. Its aesthetic appeal and hygiene properties make it suitable for medical devices, kitchen equipment, and architectural applications.

Aluminum: Lightweight yet strong, aluminum is easy to shape and mold. It's often used in aerospace and automotive industries due to its weight-saving properties. Aluminum also has good corrosion resistance, making it suitable for outdoor applications.

Copper and Brass: These materials are known for their electrical conductivity and are commonly used in electrical components. Their malleability makes them ideal for intricate Press Brake Molding.

Specialty Alloys: For more demanding applications, specialty alloys are used. These materials, designed to withstand extreme conditions, are perfect for aerospace, military, and industrial applications where standard materials might not suffice.

5.Types of Press Brake Molding

5.1 Air Bending

Air Bending is a widely used technique in press brake molding. This method involves placing the metal sheet on two points of the die, with the punch creating the bend by pushing the material into the die but not touching the bottom. The key advantage of air bending is its flexibility; it allows for different angles and bends without changing the tooling, making it highly efficient for varying designs.

5.2 Bottom Bend

Bottom Bend, also known as bottoming, is a more precise form of bending. In this method, the material is firmly pressed against the die, ensuring a sharper and more defined bend. This technique is particularly effective for materials requiring precise angle conformity and is commonly used in applications where high precision is paramount.

5.3 Coining

Coining is a high-pressure bending method where the punch and die exert significant force on the material, essentially 'coining' or imprinting the angle into the metal. This process yields very accurate bends and is used for materials that are thicker or harder, where other bending methods might not be as effective.

6.Advantages and Disadvantages of Press Brake Molding

6.1 Advantages

The Press Brake Molding process offers several advantages that make it a preferred choice in metal fabrication. Firstly, its versatility is unparalleled; it can handle a wide range of materials and thicknesses, making it suitable for various applications. Additionally, the precision and repeatability offered, especially with CNC-controlled press brakes, are crucial for industries requiring high accuracy.

Another significant advantage is the customization it offers. Press brake molding can produce both small, bespoke pieces and large-scale industrial parts, catering to a broad spectrum of needs. Furthermore, the process is relatively cost-effective, particularly for low to medium-volume productions, making it accessible for various businesses.

6.2 Disadvantages

Despite its many benefits, Press Brake Molding also has certain drawbacks. One of the main challenges is the requirement for skilled operators, especially for complex shapes and designs. This can lead to a steeper learning curve and potentially higher labor costs.

Additionally, the process can be time-consuming for very intricate designs, which may affect the overall production timeline. Another limitation is the potential for material distortion, especially when working with thinner metals, which requires careful handling and expertise to minimize.

7.What is the Difference Between Press Braking and Forming?

Understanding the difference between Press Braking and Forming is crucial in the metal fabrication industry. While both processes involve shaping metal, they employ different techniques and are suited for various applications.

Press Braking specifically refers to the process of bending sheet metal. This is achieved by placing the metal sheet between a punch and die set on a press brake machine. The machine then applies force, bending the metal at the desired angle. Press Braking is renowned for its precision, especially when controlled by CNC technology, allowing for complex bends and designs.

Forming, on the other hand, is a broader term that encompasses various methods of shaping metal, including bending, but also stretching, rolling, and forging. While Press Braking is a type of forming, not all forming processes are considered Press Braking. Forming can be performed using different equipment and techniques, depending on the desired outcome and the properties of the material being used.

In essence, the key difference lies in the scope and applications of these processes. Press Braking is more specific and focused on bending operations, offering high precision for bends, whereas Forming includes a wider array of metal shaping techniques, suitable for a variety of shapes and sizes beyond just bending.

8.What is the Difference Between Rolling and Forming?

In the realm of metal fabrication, understanding the distinction between Rolling and Forming is essential for selecting the right process for a specific application. Although both are methods of shaping metal, they utilize different techniques and serve different purposes in manufacturing.

Rolling is a metalworking process that involves passing the metal through a pair of rolls to reduce its thickness, make it uniform, or impart a desired mechanical property. Rolling is primarily used for creating flat, uniform sheets or coils and can also be used to produce various profiles and shapes. It's a continuous process and is highly efficient for mass production of similar shapes.

Forming, as mentioned earlier, is a broader term encompassing a variety of techniques used to shape metal, including but not limited to bending, stretching, and pressing. Forming can be done using a variety of tools and methods, depending on the desired outcome. Unlike rolling, which is typically used for producing long sheets or coils, forming is more versatile and can create a wide range of shapes and sizes.

The fundamental difference lies in their applications and the kind of shapes they produce. Rolling is ideal for creating long, flat products with consistent thickness, whereas forming is suitable for a broader range of shapes, offering more flexibility in terms of design and customization.

Conclusion

In conclusion, Press Brake Forming stands as a pillar in the world of metal fabrication, offering versatility, precision, and efficiency. For those seeking the pinnacle of Press Brake technology, look no further than Krrass, China's leading Press Brake manufacturer. With a commitment to innovation and quality, Krrass offers a wide range of solutions tailored to meet your fabrication needs. Explore their offerings and discover how they can enhance your manufacturing process at Krrass Press Brake.

Read More:

What is Metal Forming: Techniques, Processes, and Applications