When it comes to precision and efficiency in industrial cutting, understanding "what is the speed of 3kW laser cutting" is essential for optimizing your operations. A 3kW laser cutter offers unmatched power for slicing through various materials, from metals like steel and aluminum to more delicate substances. The cutting speed of a 3kW laser cutter depends on various factors, including the type and thickness of the material being cut, the quality of the cut desired, the type of laser (fiber, CO2, etc.), and the specific settings of the laser cutter. Generally, a 3kW laser can cut through metals like stainless steel up to around 12-15 mm thick, and for materials like carbon steel, it can cut up to about 20-25 mm thick.

But what factors influence the cutting speed, and how can you maximize productivity while ensuring high-quality results? In this article, we delve into the specifics of 3kW laser cutting speeds, breaking down the variables that affect performance and providing actionable insights to enhance your cutting processes. From material type and thickness to laser settings, we cover it all, ensuring you have the knowledge to make informed decisions for your laser cutting needs.

Fundamental Concepts of Laser Cutting

Fiber laser cutting is a precision fabrication process that harnesses high-intensity laser beams to cut materials. It is vital for one to understand the laser source’s characteristics and how different materials interact with this technology.

Laser Source and Wavelength

A fiber laser’s source and wavelength are pivotal in determining its cutting capabilities and the quality of the final output. Typically, fiber lasers operate at a wavelength of around 1.06 micrometers, allowing for a highly focused beam with increased absorption by metals. The wavelength is an intrinsic property that affects the interaction with various materials, impacting the cutting efficiency and speed.

Material Types and Compatibility

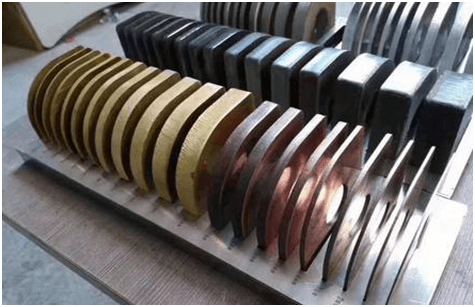

Fiber lasers are highly compatible with a variety of metal materials, including:

- Carbon steel

- Stainless steel

- Aluminum

- Copper

The compatibility between the laser and a material dictates the maximum thickness of the material that can be precisely cut, as well as the speed of the cut. Different materials require specific settings to achieve optimal cuts, which is reflected in the thickness and speed charts for fiber laser cutting. These charts are crucial resources for operators to maximize performance and precision in the cutting process.

Understanding the Cutting Speed For Laser Cutting

Speed in laser cutting is crucial for quality and efficiency. It determines how quickly the laser head moves, affecting the detail in the work. Faster speeds are suited for less detailed, larger projects, while slower speeds are necessary for intricate designs.

The speed is measured in meters or feet per minute and is vital for maintaining equipment longevity. It all depends on the size and area of the masterpiece you’re creating. A well-paced laser means less wear and tear on tools and parts, and it even cuts down on power consumption.

What Factors Affect the Cutting Speed

Material Type: Different materials absorb laser energy at varying rates, affecting the cutting speed. Metals with higher reflectivity, such as aluminum and copper, typically require lower speeds.

Laser Power: Higher-powered lasers can cut thicker materials at faster speeds. For instance, a 500W laser might cut 1mm steel at a speed of 10 m/min, while a 3kW laser can achieve 35 m/min for the same material and thickness.

Focus Position: The laser beam needs to be precisely focused. If not properly adjusted, the cutting speed can decrease, impacting the edge quality.

Assist Gases: The type and pressure of assist gases, such as oxygen, nitrogen, or air, influence the cutting speed and the quality of the cut edge.

Relationship Between Cutting Speed and Power

Speed and power are intricately linked. Generally, higher power enables cutting thicker materials or achieving a faster cutting speed. Conversely, lower power requires slower speeds for clean cuts in thin materials. Striking the right balance is crucial for optimal results. The laser cutter speed determines how well the job is to be performed.

A laser engraving machine requires the perfect balance of both speed and power to get the job done. Laser engraving is one of the more difficult parts of laser cutting. It depends on the utmost precision and skills. If the link between the speed and power of the cutting machine is not maintained, the engraving can be completely ruined.

How Laser Power and Speed Affect Cutting

At first glance, it may seem ideal to use more power and speed in laser cutting, as high power ensures even thick materials are cut through efficiently. However, using excessive force isn't always the best approach. While a powerful laser can cut quickly, it is not suitable for all materials. If not chosen correctly, it can compromise the quality of the cut and even damage the material, despite the advanced technology involved. Finding the right balance is crucial to achieving optimal results in laser cutting.

High Laser Power

This setting is only suitable for certain types of material sizes and thicknesses. This can increase the speed of the process a lot. The best features of high laser power are:

- Cuts thicker materials

- Faster cutting speeds

- Increased risk of heat damage and melt

- Wider cut width

Low Laser Power

Low-power laser cutting machines operate efficiently without subjecting the material to excessive heat, thus avoiding damage. However, they are best suited for thinner materials. While low-power lasers offer greater control and precision, they struggle to achieve clean cuts on thicker materials. Therefore, the key advantages of using low-power laser settings are:

- Cuts thinner materials

- Slower cutting speeds

- Reduced heat damage and melt

- Narrower cut width

High Laser Speed

Different materials react differently to laser cutting. The best features of this setting are:

- Higher efficiency

- Potential for Incomplete Cuts

- Quality Issues

Low Laser Speed

Slower speeds can enhance precision and result in cleaner edges. The features of this setting are:

- Greater Precision

- Increased HAZ

- Risk of Burn Marks

How To Choose Power And Speed For Optimal Cutting Effect

Consider the material: Different materials require different power and speed settings. For example, denser materials like hardwood or acrylic may require higher power and slower speeds, while softer materials like paper or fabric may need lower power and faster speeds. Always test your settings on a small piece of the material before proceeding with your project.

Adjust for desired depth: If you want a deeper engraving or cut, increase the power or decrease the speed. Conversely, if you want a shallower result, decrease the power or increase the speed. Remember that increasing the power too much can cause damage to your material or machine, so always test your settings first.

Balance power and speed for efficiency: While higher power and slower speeds may produce deeper results, they can also take longer to complete and may cause more wear and tear on your machine. Experiment with different power and speed combinations to find the most efficient settings for your project.

Test and iterate: It's essential to test your settings on a small piece of the material before proceeding with your project. This will help you fine-tune your power and speed settings and avoid costly mistakes. Don't be afraid to make adjustments and try different combinations to achieve the best results.

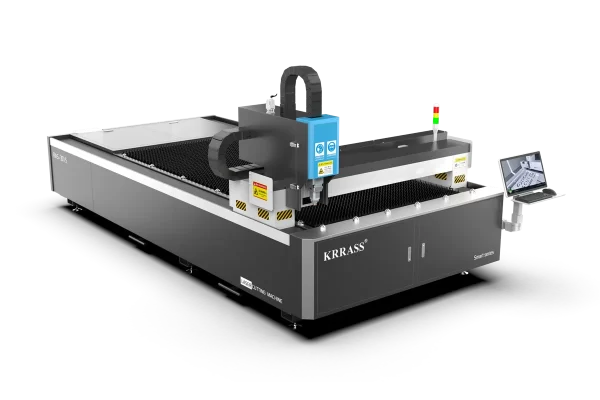

3000W Laser Cutter - Importance & Application

1. Material Versatility

A 3000W laser cutter offers a powerful combination of efficiency, precision, and versatility, making it suitable for a wide range of industrial applications. Here are some key insights to consider when working with a 3000W laser cutter:

- Metals: Capable of cutting various metals including mild steel, stainless steel, and aluminum.

- Non-metals: Can also be used for certain plastics and composites, though typically less common.

- Thickness: Efficiently cuts thin to medium-thickness materials. For example, it can cut mild steel up to around 20mm thick, stainless steel up to about 12mm, and aluminum up to approximately 10mm.

2. Cutting Speed and Quality

- High Speed: Provides fast cutting speeds, especially for thinner materials, enhancing productivity.

- Precision: Ensures high precision and clean edges, important for applications requiring detailed work and minimal post-processing.

- Quality: Maintains excellent cut quality with minimal thermal distortion and a small heat-affected zone.

3. Efficiency and Cost-Effectiveness

- Operational Efficiency: Reduces production time due to faster cutting speeds and less need for secondary operations.

- Energy Consumption: Balances energy use with cutting efficiency, offering a cost-effective solution for medium to high-volume production runs.

4. Optimizing Performance

- Assist Gases: Use of appropriate assist gases (like oxygen for steel or nitrogen for stainless steel and aluminum) can significantly impact cutting speed and quality.

- Settings Adjustment: Fine-tuning parameters such as laser power, cutting speed, and focus position is essential for optimizing performance for different materials and thicknesses.

5. Applications

- Industrial Manufacturing: Widely used in automotive, aerospace, and heavy machinery industries for cutting complex parts and components.

- Custom Fabrication: Ideal for custom metalwork, signage, and decorative pieces due to its precision and versatility.

- Prototyping: Excellent for creating prototypes with high accuracy, allowing for rapid design iterations.

Explore 3000W Laser Cutting Capabilities

A 3000W laser cutting system typically refers to a laser cutter with a power output of 3000 watts. 3kW fiber lasers were widely used in laser cutting and had become increasingly popular in industrial applications. Fiber lasers have several advantages over other types of lasers, such as CO2 lasers, including higher efficiency, better beam quality, and lower maintenance requirements.

What Is the Speed of 3KW Laser Cutting

As we menetioned before, the speed of 3kW laser cutting can vary depending on several factors, including the material being cut, its thickness, the type of laser system, and the specific machine settings. However, generally speaking, a 3kW laser cutting system is capable of achieving relatively high cutting speeds compared to lower wattage options. Here are some examples of cutting speeds for a 3kW laser cutting system based on typical materials and thicknesses:

- Mild Steel:

- Thickness: 1 mm

- Cutting Speed: Approximately 10-15 meters per minute

- Stainless Steel:

- Thickness: 2 mm

- Cutting Speed: Around 8-12 meters per minute

- Aluminum:

- Thickness: 3 mm

- Cutting Speed: Approximately 6-10 meters per minute

- Acrylic:

- Thickness: 5 mm

- Cutting Speed: Around 2-4 meters per minute

- Wood:

- Thickness: 6 mm

- Cutting Speed: Approximately 3-6 meters per minute

What's the max thickness of 3KW Laser Cutting

The maximum thickness that a 3kW laser can cut depends on several factors including the type of material being cut, its reflectivity, and the quality of the laser system. Generally, a 3kW laser can cut through metals like stainless steel up to around 12-15 mm thick, and for materials like carbon steel, it can cut up to about 20-25 mm thick. However, these are approximate values and may vary based on specific machine capabilities and material properties. It's always best to consult with the manufacturer or supplier for precise specifications and recommendations for your cutting needs.

Summary of Laser Cutting Thickness & Speed Chart

Different laser powers, thicknesses, and material types have different cutting speeds. The following lists the laser cutting speeds for different metal types using IPG lasers.

1. Carbon steel

| Thickness(mm) | IPG 1000W | IPG 1500W | IPG 2000W | IPG 3000W | IPG 4000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 15.0-22.0 | 18.0-25.0 | 25.0-33.0 | 28.0-38.0 | 30.0-44.0 |

| 2 | 5.0-6.6 | 7.0-10 | 7.0-10 | 5.5-7.0 | 5.5-7.7 |

| 3 | 2.5-3.85 | 4.0-5.5 | 4.0-5.5 | 3.6-5 | 3.7-5.5 |

| 4 | 2.0-3.3 | 2.5-3.5 | 2.8-4.0 | 3.0-4.5 | 3.5-4.62 |

| 5 | 1.4-2.0 | 2.0-2.8 | 2.0-2.75 | 2.5-3.3 | 2.5-4.0 |

| 6 | 1.2-1.65 | 2.0-2.42 | 2.0-2.42 | 2.3-2.86 | 2.5-3.52 |

| 8 | 0.9-1.32 | 1.2-1.65 | 1.2-1.65 | 1.8-2.2 | 2.0-2.8 |

| 10 | 0.6-0.9 | 1.0-1.32 | 1.0-1.32 | 1.21-1.65 | 1.2-2.2 |

| 12 | 0.4-0.7 | 0.7-1.0 | 0.7-1.0 | 1.0-1.32 | 1.0-1.76 |

| 16 | 0.6-0.8 | 0.6-0.8 | 0.6-0.9 | 0.7-1.0 | |

| 20 | 0.5-0.8 | 0.6-0.9 | |||

| 22 | 0.66-0.9 |

| Thickness(mm) | IPG 6000W | IPG 8000W | IPG 10000W | IPG 12000W | IPG 15000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 35.0-48.0 | 60.0-70.0 | 65.0-75.0 | 66.0-80.0 | 70.0-90.0 |

| 2 | 6.0-8.25 | 6.8-7.2 | 7.0-7.5 | 7.2-7.8 | 7.5-8.2 |

| 3 | 4.0-5.5 | 4.7-5.3 | 5.0-5.5 | 5.2-5.8 | 5.5-6.0 |

| 4 | 3.5-5.0 | 3.8-4.3 | 4.0-4.5 | 4.2-4.6 | 4.5-5.2 |

| 5 | 3.0-4.2 | 3.3-3.8 | 3.6-4.0 | 3.8-4.2 | 4.0-4.5 |

| 6 | 2.6-3.52 | 3.0-3.4 | 3.3-3.7 | 3.5-4.0 | 3.8-4.3 |

| 8 | 2.0-2.8 | 2.3-2.6 | 2.5-2.8 | 2.6-3.0 | 2.8-3.5 |

| 10 | 1.8-2.3 | 2.0-2.5 | 2.3-2.6 | 2.5-3.0 | 2.6-3.0 |

| 12 | 1.6-2.1 | 1.7-2.2 | 1.9-2.2 | 2.0-2.3 | 2.5-3.0 |

| 16 | 0.7-1.0 | 1.2-1.4 | 1.3-1.5 | 1.4-1.6 | 1.7-2.0 |

| 20 | 0.65-0.95 | 1.0-1.1 | 1.1-1.2 | 1.1-1.4 | 1.3-1.5 |

| 22 | 0.6-0.77 | 0.9-1.0 | 0.9-1.0 | 0.9-1.2 | 1.1-1.3 |

| 25 | 0.4-0.65 | 0.6-0.7 | 0.6-0.7 | 0.6-0.8 | 0.9-1.2 |

| 30 | 0.6-0.8 |

Postscript:

Carbon steel is an iron-carbon alloy with a carbon content between 0.02% and 2%.

The carbon steels that fiber lasers can cut include low carbon steel (mild steel), medium carbon steel (M2 steel) and high carbon steel (tool steel).

Fiber laser cutters can easily cut carbon steels ranging from 1mm to over 200mm at speeds from 0.12m/min to 100m/min, with optional powers starting from 1000W and up to 60000W, and working gas options include air, oxygen, nitrogen and mixed gases.

Stainless steel

| Thickness(mm) | IPG 1000W | IPG 1500W | IPG 2000W | IPG 3000W | IPG 4000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 16.5-22.0 | 20.0-26.0 | 27.5-33.0 | 31.0-38.5 | 33.0-45.0 |

| 2 | 4.5-6.1 | 18.0-22.0 | 18.0-22.0 | 10.0-16.5 | 10.0-20.0 |

| 3 | 2.0-3.1 | 4.5-5.5 | 4.5-5.5 | 7.0-10 | 7.5-12.0 |

| 4 | 1.0-1.65 | 2.0-2.5 | 2.2-2.8 | 5.0-7.2 | 5.5-9.0 |

| 5 | 0.4-0.7 | 1.5-2.0 | 1.5-2.0 | 1.8-2.45 | 4.0-5.5 |

| 6 | 0.2-0.45 | 0.7-3.1 | 0.7-1.32 | 1.0-1.65 | 2.6-4.5 |

| 8 | 0.2-0.45 | 0.35-0.6 | 1.2-2.0 | 1.6-2.8 | |

| 10 | 0.7-1.0 | 0.7-1.65 | |||

| 12 | 0.5-0.9 |

| Thickness(mm) | IPG 6000W | IPG 8000W | IPG 10000W | IPG 12000W | IPG 15000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 50.0-65.0 | 63.0-66.0 | 68.0-72.0 | 70.0-80.0 | 75.0-90.0 |

| 2 | 30.0-40.0 | 40.0-44.0 | 42.0-46.0 | 44.0-48.0 | 46.0-50.0 |

| 3 | 18.0-25.0 | 25.0-28.0 | 27.0-30.0 | 28.0-35.0 | 30.0-38.0 |

| 4 | 10.0-15.5 | 15.0-18.0 | 18.0-21.0 | 20.0-26.0 | 22.0-28.0 |

| 5 | 8.0-13.5 | 12.0-14.0 | 14.0-16.0 | 15.0-20.0 | 16.0-22.0 |

| 6 | 6.0-9.0 | 9.0-9.5 | 10.0-10.5 | 11.0-13.0 | 12.0-15.0 |

| 8 | 4.0-5.5 | 5.0-5.3 | 6.5-6.8 | 7.0-7.5 | 7.5-8.5 |

| 10 | 1.8-2.8 | 3.8-4.0 | 4.7-5.0 | 5.0-5.5 | 5.5-6.5 |

| 12 | 1.2-1.65 | 2.5-2.7 | 2.8-3.0 | 3.0-3.5 | 3.3-4.0 |

| 16 | 0.8-1.2 | 1.8-1.9 | 2.2-2.4 | 2.3-2.8 | 2.5-3.0 |

| 20 | 0.6-0.9 | 1.3-1.5 | 2.0-2.2 | 2.1-2.5 | 2.3-2.8 |

| 22 | 0.7-0.8 | 1.2-1.3 | 1.4-1.7 | 1.5-1.9 | |

| 25 | 0.5-0.6 | 0.7-0.8 | 0.7-1.0 | 0.9-1.2 | |

| 30 | 0.5 | 0.5-0.7 | 0.6-0.8 | ||

| 35 | 0.4-0.5 | 0.5 | |||

| 40 | 0.3 | 0.3 | |||

| 45 | 0.3 |

Postscript:

Stainless steel refers to an alloy steel that is passive, corrosion-resistant, rust-free, and contains high chromium (usually 12%~30%) in the atmosphere and corrosive media such as acids, alkalis, and salts, which contains nickel, molybdenum, vanadium, manganese, tungsten and other elements, also known as acid-resistant steel, white iron, water copper iron.

The ASTM grades and models of Stainless Steel that fiber lasers can cut include 201, 202, 205, 301, 302, 302B, 302Cu, 303, 304, 304L, 304N, 305, 308, 309, 310, 314, 316, 316L, 316N, 317 , 317L, 321, 329, 330, 347, 384, 403, 405, 409, 410, 414, 416, 420, 422, 429, 430, 430F, 431, 434, 436, 439, 440 (440A, 44 0B, 440C ), 444, 446, 501, 502, 904L and 2205.

Fiber Laser Cutting Machines are capable of cutting stainless steel as thin as 1 millimeter and as thick as 150 millimeters at speeds as low as 0.05 meters per minute and as high as 100 meters per minute, with laser powers ranging from 1000 watts to 60000 watts, and optional working gases of N₂ and Air.

Aluminum

| Thickness(mm) | IPG 1000W | IPG 1500W | IPG 2000W | IPG 3000W | IPG 4000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 10.0-13.2 | 15.0-27.5 | 25.0-31.0 | 25.0-40.0 | 26.0-44.0 |

| 2 | 2.0-4.5 | 7.0-8.6 | 10.0-13.2 | 10.0-20.0 | 10.0-22.0 |

| 3 | 0.6-1.32 | 5.0-6.5 | 5.0-6.6 | 5.0-6.6 | 8.0-12.0 |

| 4 | 1.0-1.65 | 1.5-2.2 | 3.0-4.0 | 4.5-8.25 | |

| 5 | 0.6-0.9 | 1.0-1.32 | 2.0-2.65 | 3.5-5.5 | |

| 6 | 0.4-0.7 | 0.6-0.9 | 1.0-1.65 | 2.2-4.5 | |

| 8 | 0.4-0.7 | 0.5-0.8 | 1.2-2.0 | ||

| 10 | 0.3-0.45 | 0.8-1.65 | |||

| 12 | 0.6-0.9 | ||||

| 14 | 0.3-0.66 |

| Thickness(mm) | IPG 6000W | IPG 8000W | IPG 10000W | IPG 12000W | IPG 15000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 50.0-60.0 | 53.0-65.0 | 55.0-70.0 | 60.0-80.0 | 65.0-85.0 |

| 2 | 25.0-38.5 | 30.0-40.0 | 33.0-42.0 | 35.0-45.0 | 38.0-50.0 |

| 3 | 13.0-20.0 | 15.0-23.0 | 18.0-26.0 | 22.0-35.0 | 25.0-38.0 |

| 4 | 10.0-13.2 | 12.0-16.0 | 15.0-18.0 | 17.0-24.0 | 20.0-26.0 |

| 5 | 5.0-8.8 | 7.0-10 | 11.0-15.0 | 14.0-20.0 | 17.0-22.0 |

| 6 | 4.0-6.6 | 5.0-7.0 | 9.0-11.0 | 12.0-17.0 | 14.0-18.0 |

| 8 | 2.0-3.3 | 2.5-4.0 | 4.0-6.0 | 9.0-11.0 | 11.0-15.0 |

| 10 | 1.0-2.3 | 1.5-2.8 | 2.5-3.5 | 3.5-4.5 | 4.0-5.0 |

| 12 | 0.8-1.55 | 1.0-1.6 | 1.5-2.0 | 2.0-3.0 | 2.3-3.2 |

| 14 | 0.6-0.9 | 0.8-1.2 | 1.0-1.5 | 1.5-1.8 | 1.7-2.1 |

| 16 | 0.4-1.0 | 0.6-0.8 | 0.7-1.0 | 1.1-1.4 | 1.3-1.6 |

| 20 | 0.5-0.7 | 0.5-0.8 | 1.0-1.2 | 1.1-1.4 | |

| 25 | 0.3 | 0.5-0.7 | 0.7-1.0 | 1.0-1.2 | |

| 30 | 0.3-0.5 | 0.5-0.7 | 0.6-0.8 | ||

| 35 | 0.3 | 0.4-0.5 | 0.5-0.6 | ||

| 40 | 0.3 | 0.4-0.5 | |||

| 50 | 0.3 | 0.3 | |||

| 55 | 0.3 |

Postscript:

Aluminum is the most abundant silver-white light metal, which is soft and ductile.

Lasers can easily cut through foils, sheets, strips, tubes, rods and profiles made of aluminum and alloys.

Fiber laser cutting systems are ideal for cutting rolled aluminum, cast aluminum, pure aluminum alloy, aluminum alloys with copper, manganese, silicon, magnesium and zinc up to 100mm thick at a maximum speed of 70m/min, with laser power options from 1000W to 40000W and the N₂ working gas.

Brass

| Thickness(mm) | IPG 1000W | IPG 1500W | IPG 2000W | IPG 3000W | IPG 4000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 14.0-20.0 | 30.0-38.5 | 30.0-38.5 | 20.0-31.0 | 25.0-38.5 |

| 2 | 3.0-4.5 | 4.0-7.2 | 7.7-8.8 | 7.0-13.2 | 8.0-13.2 |

| 3 | 1.0-1.55 | 2.5-3.1 | 3.0-4.5 | 5.0-7.2 | 5.5-7.7 |

| 4 | 1.0-1.2 | 1.32-1.8 | 1.8-2.42 | 3.5-5.5 | |

| 5 | 0.6-0.9 | 0.6-0.9 | 1.0-1.65 | 2.0-3.52 | |

| 6 | 0.4-0.66 | 0.8-1.32 | 1.4-2.2 | ||

| 8 | 0.3-0.45 | 0.8-1.32 | |||

| 10 | 0.2-0.45 |

| Thickness(mm) | IPG 6000W | IPG 8000W | IPG 10000W | IPG 12000W | IPG 15000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 45.0-55.0 | 48.0-60.0 | 50.0-62.0 | 55.0-65.0 | 60.0-75.0 |

| 2 | 25.0-33.0 | 27.0-32.0 | 30.0-35.0 | 32.0-40.0 | 35.0-45.0 |

| 3 | 12.0-20.0 | 13.0-20.0 | 15.0-21.0 | 16.0-22.0 | 18.0-25.0 |

| 4 | 8.0-11.0 | 10.0-12.0 | 11.0-13.0 | 12.0-15.0 | 14.0-18.0 |

| 5 | 6.0-7.7 | 7.0-9.0 | 8.0-11.0 | 10.0-14.0 | 12.0-16.0 |

| 6 | 3.5-50 | 4.0-5.5 | 5.0-7.5 | 8.0-13.0 | 10.0-13.0 |

| 8 | 1.6-2.42 | 2.0-2.5 | 3.0-4.5 | 5.5-6.5 | 7.0-8.5 |

| 10 | 0.8-1.32 | 1.6-2.2 | 2.0-2.5 | 3.5-4.7 | 5.0-6.5 |

| 12 | 0.8-1.2 | 1.1-2.0 | 1.7-2.8 | 2.0-3.5 | |

| 15 | 0.8-1.2 | 1.0-1.6 | 1.5-2.2 | ||

| 18 | 0.6-0.8 | 0.8-1.2 | |||

| 20 | 0.6-0.8 | 0.5-0.8 |

Brass is a soft, ductile metal known for its excellent electrical and thermal conductivity, ductility, and corrosion resistance. As an alloy of copper and zinc, it boasts high mechanical properties and impressive wear resistance.

Lasers are capable of easily cutting through brass, making them ideal for producing precision instruments, ship components, electronic parts, gun shells, musical instruments, decorative items, coins, and molds.

Apart from traditional copper and brass, fiber lasers demonstrate the capability to cut a diverse range of alloys including aluminum bronze, manganese bronze, aluminum brass, gun metal (tin-zinc bronze), white copper, and nickel-copper alloy (Monel). These lasers can handle material thicknesses ranging from 1mm to 80mm, achieving cutting speeds between 0.4m/min to 65m/min. Laser powers range from as low as 1000W to as high as 40000W, with the use of nitrogen for cutting brass and oxygen for cutting copper.

Choose Krrass Machinery for Your Fiber Laser Needs

When it comes to choosing the right fiber laser wattage for your business, Krrass Machinery can help you make an informed decision. Our selection of laser machines includes varying wattage and excellent quality. Our expert team can assist you in choosing the machine that fits best for your particular requirements and provide you with the necessary support to maximize your investment.

With Krrass Machinery, you can expect:

- Quality equipment that is built to last

- Expert advice and support to help you make informed decisions

- Competitive pricing to fit your budget

- A commitment to customer satisfaction

Contact us today to learn more about our laser machines and how they can help you optimize your business operations. Let us help you choose the correct laser wattage to take your business to the next level.