In today’s society, with the rising labor costs and increasingly demanding product requirements, numerous companies are constantly raising the bar for the performance and quality of their production equipment.

The CNC plate bending machine, a crucial piece of equipment in the forging machine tool and sheet metal industries, has also been evolving. In recent years, we have introduced the hybrid servo electric press brake energy-saving series.

So, why is the hybrid press brake a better choice? Why should you opt for it?

Let’s explore the upgrades of the CNC plate bending machine and the advantages of the hybrid electric servo press brake.

Newly Upgraded CNC Hydraulic Press Brake: The Servo Electric Series

Press Brake Upgrades

The evolution of the bending machine has progressed through several stages:

- Manual press brake: Employed mechanical synchronization.

- NC press brake for sale: Utilized torsion axis synchronization.

- CNC press brake: Featured electro-hydraulic synchronization.

- Servo electric press brake: Driven and controlled by servo motors.

Previously, bending machines mainly relied on torsion axis synchronization or valve control. However, the Hybrid Servo CNC brake press represents a true pump-controlled machinery, with the synchronization of the machine tools depending on pump control.

Overall Development Trends

As human technology advances, so does the bending machine.

- It has transitioned from manual operation to numerical control and is now moving towards more advanced robotics and automation.

- From simple bending tasks, it has evolved to handle complex machining.

- The speed has increased from slow to fast and now even to super high speed.

- Precision has improved from low to high.

- And it has shifted from noisy operation to quiet, low-noise work.

After years of research, development, and refinement, the servo electric press brake, as a new-generation hydraulic CNC bending machine, has emerged as an excellent option for users. When compared to previous generations of hydraulic bending machines, its advantages are quite evident. Now, let’s analyze the outstanding benefits of the hybrid electric press brake machine.

Advantages of the Hybrid Servo Electric Press Brake

Currently, the future trend of the sheet metal equipment industry is geared towards environmental protection, energy conservation, high efficiency, automation, and unmanned operation.

The EPP series servo electric hybrid CNC press brake produced by KRRASS came into being, perfectly embodying the superior performance in terms of energy savings, high efficiency, automation, and unmanned operation.

Environmental Protection and Energy Conservation

First and foremost, let’s consider the advantages in environmental protection and energy conservation.

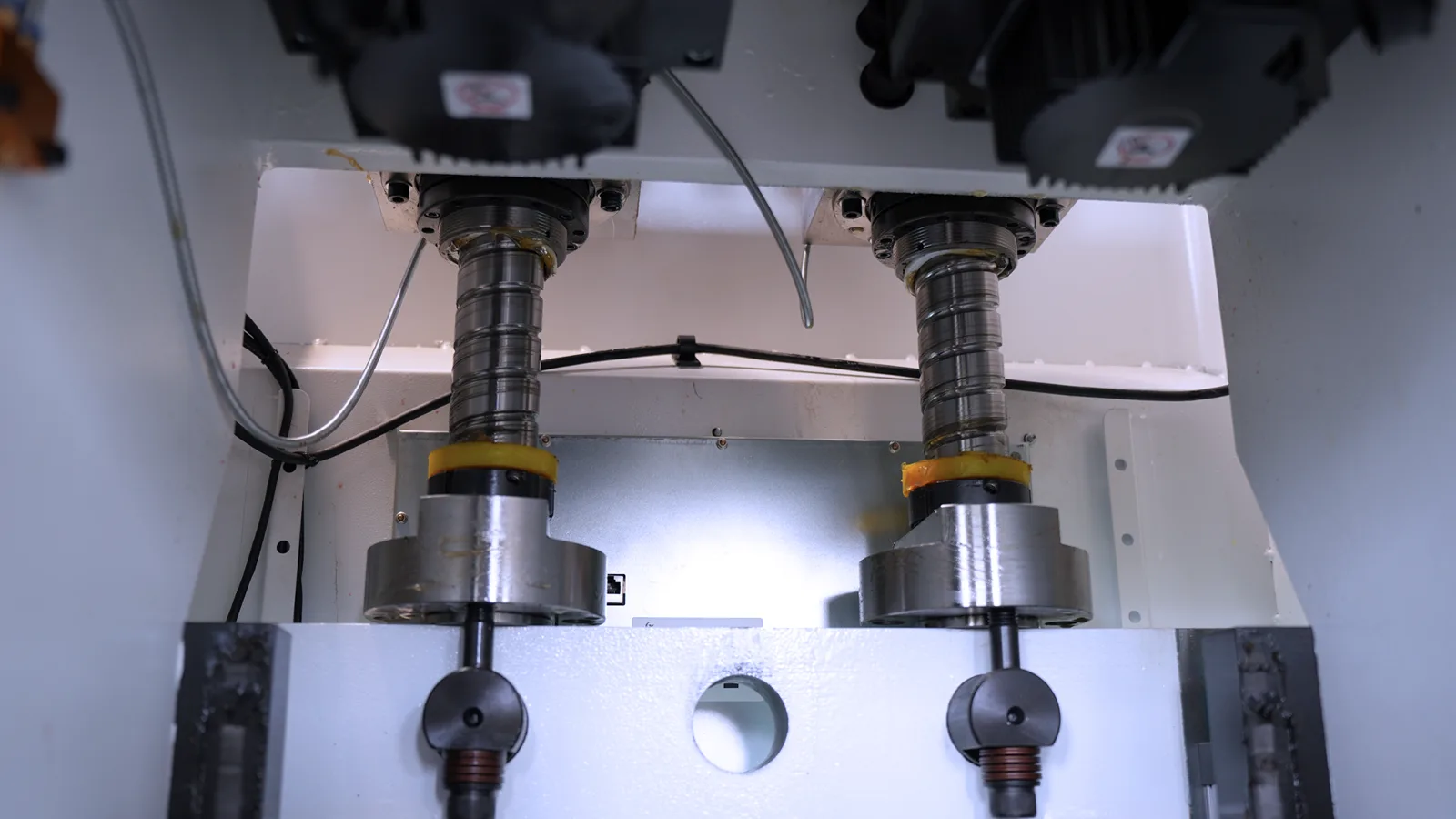

The EPP Series Hybrid Servo bending machine, employs the world’s most advanced dual servo pump control system drive, which we’ll refer to as servo motor drive hereafter.

The servomotor replaces the traditional servo/proportional valve control technology. This drive solution not only saves more space but also reduces oil consumption and energy usage compared to conventional hydraulic systems. In fact, the amount of hydraulic oil required is only about 1/3 to 1/5 of that in ordinary hydraulic systems.

Power Consumption and Energy Efficiency

The EPP series servo motor-driven hybrid CNC bending machine, offers advantages in power consumption and energy efficiency.

Compared to traditional bending system modes, its energy efficiency is remarkably high. This is because the system only utilizes the energy necessary for the pressure at each stage.

Most of the pressure bottlenecks are reduced and offset. Consequently, energy consumption can be cut by more than 75%. In standby mode, the energy consumption is at its lowest, accounting for only about 5% of other systems.

High Efficiency and High Speed

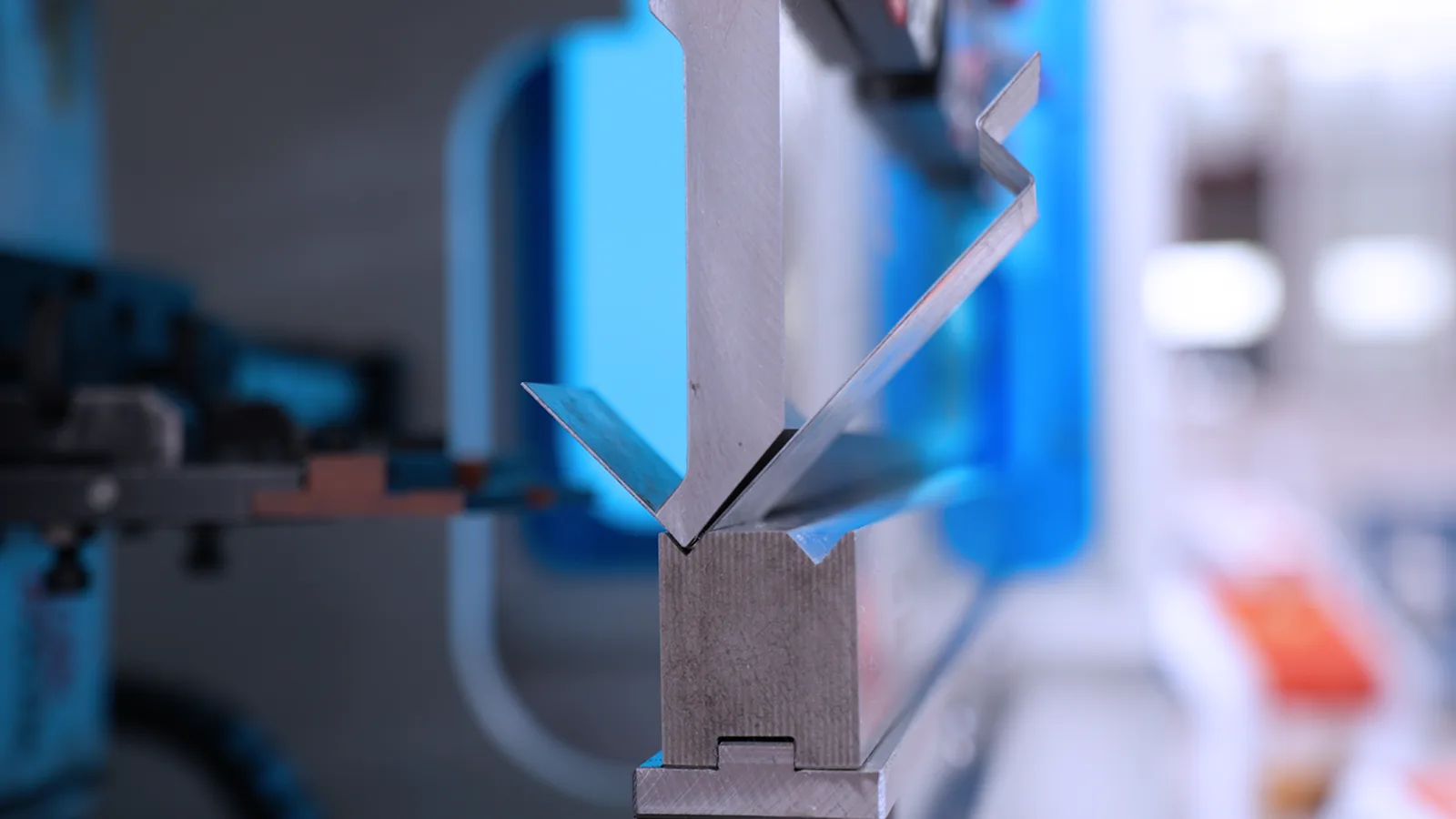

The EPP Series Servo Drive Hybrid CNC press brake for sale, stands out in terms of high efficiency, with speed being the key factor.

While ensuring bending accuracy, its no-load and working speeds can be boosted by 15% – 25% compared to ordinary bending machines. The return speed can reach over 1.5 times that of the norm. This significant improvement has greatly enhanced productivity.

Stable Temperature Control and Long Service Life

Thanks to its outstanding hydraulic system, we can maintain a stable oil temperature range even after prolonged periods of rapid operation. When the external ambient temperature is 38 °C, the hydraulic oil temperature will not exceed 50 °C.

This makes it suitable for factories in high-temperature regions, such as South China, Southeast Asia, and countries near the equator. Users no longer need to worry about rising oil temperatures, and it also extends the service life of the bending equipment.

Automation and Robotics

The servo electric motor press brake machine for sale can perform automatic program calculations, laser automatic detection, automatic feedback and recognition of test results, automatic compensation, and anti-collision control.

Furthermore, it can achieve true unmanned operation. Its seamless cooperation with robots can bring about a fully automated factory. Staff members only need to operate the computer system in the office to complete the entire process, from ordering and blanking to production, transportation, and the final product. It can operate continuously for extended periods.

The servo electric press brake machine not only offers high precision, energy savings, and low noise but is also more stable and reliable, with lower oil consumption. This makes it conducive to the manufacturing of large-stroke and ultra-high-speed bending machines.

In the coming year 2025, servo press brakes will gain even more popularity. It’s definitely worth giving them a try!