Sheet metal fabrication plays a critical role in the manufacturing industry, finding applications in construction, automotive, aerospace, and various other fields. The versatility of sheet metal, along with its ability to be molded into different shapes and sizes, makes it a popular choice for creating complex and intricate designs.

However, to ensure the success of any sheet metal fabrication project, it is essential to have a solid understanding of design principles and best practices. This article serves as a comprehensive guide to sheet metal fabrication design, offering tips for material selection, geometric constraints, and cost-effective design strategies.

Whether you're an experienced engineer or a novice designer, this guide will assist you in creating high-quality sheet metal parts that meet the requirements and specifications of your project.

Overview of Sheet Metal Fabrication

In manufacturing, sheet metal refers to anything thinner than 0.25 inches. All sheet metal parts must have a consistent width, which limits their applications but ensures durability and longevity.

Sheet metal parts are commonly used in applications such as automobile chassis, where the strength-to-weight ratio is crucial. Due to their lower thickness, sheet metal parts are generally hollow, resulting in reduced weight without compromising load-bearing capacity.

While precision processes may not be necessary for simple applications, avoiding precision sheet metal fabrication for high-value applications is impractical as it may lead to equipment damage due to wear and tear.

The Working Principle

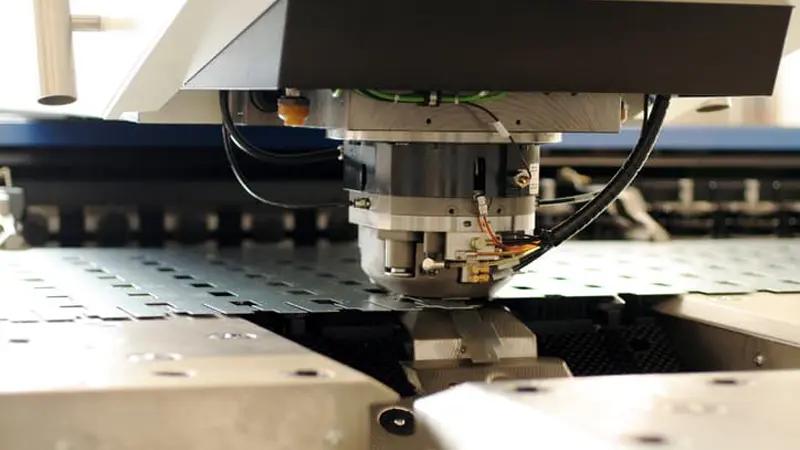

The working principle behind sheet metal fabrication is relatively straightforward. It relies on the elasticity of the metal and the fact that cold-rolled metal provides better durability. Sheet metal fabrication involves two main methods: cutting and forming.

As the name suggests, cutting involves removing a portion of the sheet to achieve the desired shape. Forming, on the other hand, is a more complex process consisting of three different processes that work together to create the required form. Design and manufacturability must be carefully considered in the process to minimize waste and ensure perfection.

In most cases, manufacturers rely on CAD files in either the DXF or DWG format to ensure compliance with the design. Cutting and forming processes often work in tandem to expedite results in most projects. While sheet metal fabrication typically requires no post-processing, some finishing and joining techniques may be necessary depending on the application.

The 4 Main Sheet Metal Fabrication Techniques

Sheet metal fabrication involves two primary processes: forming and cutting. These techniques work together to shape the final product. Cutting is a relatively simple process, while forming includes stamping, bending, and punching as sub-techniques.

Here are the key details about the main techniques used in creating sheet metal parts:

1 - Cutting

The cutting process removes excess sheet metal to achieve the final form. There are three main approaches to cutting sheet metal:

- Laser cutting

- Plasma cutting

- Water jet cutting

2 - Bending

The bending process applies significant force at a specific point on the sheet metal to obtain the desired shape. In some cases, the area under the bend may require preparation, such as bend notches, which indicate the bend location and facilitate the process.

3 - Stamping

Stamping is a complex process that combines shearing, bending, and stretching to create complex parts efficiently. Manufacturers often choose stamping for time-sensitive projects that require intricate designs.

4 - Punching

Punching involves using different techniques, including shearing, bending, and stretching, to create new shapes from sheet metal. Some punching processes even involve joining multiple pieces using various techniques.

The Main Advantages and Limitations of Using Sheet Metal for Fabrication

Sheet metal parts offer several advantages that make them popular in many industries. However, there are also limitations to consider. Understanding these advantages and limitations is crucial for manufacturers to determine the appropriate applications for sheet metal.

| Advantages | Disadvantages |

|---|---|

| Quick turnaround when compared to other manufacturing methods. | Difficult to make complex designs with intricate details, which can limit the range of shapes and forms that can be produced. |

| High-quality parts for both production and prototyping. | Requires significant investment for tooling and other equipment, which can be a barrier to small-scale production. |

| Versatile enough to work with several metals, such as steel, aluminum, and copper. | Have longer lead times compared to other fabrication methods due to the multiple stages involved in the process, such as cutting, forming, and finishing. |

| Delivers a high strength-to-weight ratio because of the hollow design. | Requires skilled labor, which can be expensive. |

| Needs no post-processing in most cases. |

Guidelines for Sheet Metal Fabrication Design

As mentioned earlier, sheet metal fabrication design requires attention to specific requirements that vary based on the overall product design. Simple products may have fewer requirements, while intricate geometries may necessitate additional processes for market readiness.

Sheet metal fabrication generally follows a set of best practices to ensure perfection and deliver the highest quality in the shortest time. The following five categories encompass the general guidelines for sheet metals:

Tolerances

Tolerance is a critical parameter in various applications. The general rule of thumb is that higher precision requires more resources and incurs additional costs. Therefore, tolerances should align with the application.

For example, in the automobile industry, the precision required for the door or body parts is typically lower than that required for the chassis or other integral components. While tolerance requirements depend on project-specific needs, relying on set quality standards can help maintain consistency and performance. Compliance with industry standards also facilitates meeting industrial requirements and building consumer trust in the brand.

The prevalent standard for sheet metal fabrication is ISO 2768, which covers tolerance requirements across multiple industries while maintaining a balance between costs and processing capabilities.

General Tolerances

Sheet metal fabrication follows several general tolerances that are universally used in compliance with international standards. However, sensitive applications like aerospace and automotive may have exceptions to these standards due to the criticality of precision for optimal performance.

| Feature | Prevalent Tolerance Range | Additional Notes |

|---|---|---|

| Wall thickness | 0.9mm to 20mm | |

| Offsets | 0.3mm to 0.7mm | |

| Curls | >2x material thickness | Anything less than the recommended curl dimension would make the sheet brittle. |

| Bends | 0.9mm–1.2mm; 1.8mm–2.4mm; 3.8mm–5.0mm; 7.5mm–10mm; 15mm–20mm | A +/- degree deviation is expected on all bends. Moreover, any other specifications will add to your costs. |

| Hems | Inside dia = material thickness with return length to be 4x the thickness | |

| Countersinks | Major dia = +/- 0,254 mm; Minor dia > 2/3 thickness | |

| Holes and slots | Dia > material thickness | A diameter less than the material thickness would cause cracks in the sheet. |

| Notches and tabs | Notch width > 1.5x thickness; Length > 5x thickness |

Forming Basics

Forming involves bending a flat sheet of metal into a predetermined shape by applying pressure. The process requirements and details vary depending on the type of bending process. While numerous methods exist, the following three are the most common for sheet metal bending:

- Brake pressing: This manual process uses a clamping bar and a plate to form the metal sheet. It is suitable for prototyping and small-scale productions.

- Roll bending: This method produces results in the form of cylinders, cones, or other arcs, while following the same principles as brake pressing.

- Press brake bending: This advanced bending process utilizes hydraulic machines with punches and dies. It is suitable for metal sheets up to 6mm thick and allows for precise features.

Integral Parameters for Sheet Metal Bending

When it comes to the bending process, several parameters must be considered by manufacturers and designers. Adhering to these design requirements is crucial for characterizing any sheet metal bend and ensuring excellent results.

Here are the six most important parameters for sheet metal bending operations:

- Bend Line: The bend line is a straight line on the sheet's surface that marks the beginning and end on both sides of the bend. The industry standard for bend lines is to maintain a distance of 5 times the sheet thickness between the inside edge and outside of the bend.

- Bend Radius: The bend radius refers to the distance from the bend axis to the inner surface of the material between two bend lines. It is generally advisable to use a bend radius that is at least as large as the material thickness. A larger bend radius is even better, as using a smaller radius than the material thickness can reduce the load-bearing capacity of the part.

- Bend Angle: The bend angle is the angle created by the bend with the imaginary perpendicular line coming from the axis. While there is no specific number for the bend angle, it is recommended to ensure that the flange length is four times the thickness. Keeping all bend angles the same is also good practice.

- Neutral Axis: The neutral axis is the portion of a sheet that remains at its original length without stretching or compressing. While there is no legal limit or guideline for its location, the accuracy of other factors, such as bend radius and angle, plays a crucial role in determining the performance of the final product. Precise factors lead to better product performance.

- The K-Factor: The K-factor of a material is a measure of its location, determined by dividing the distance between the material and its thickness (t) by its T. The K-factor is influenced by factors such as the material type, bending process, and bend angle. To achieve optimal results, the K-factor should fall within the range of 0.25 to 0.50. The K-factor can be calculated using the formula K = T/t.

- Bend Allowance: To create accurate and consistent bent parts, it is important to measure and account for the arc length and the distance between the neutral axis and the bend lines. Accurate bend allowances appropriate for the material, thickness, and type of bending process (e.g., air bending, bottom bending, or coining) should be used.

Cutting Basics

Cutting is another essential process in sheet metal fabrication. In many cases, it offers a simpler alternative that provides fast results with acceptable precision. During the design phase, sheet metal design guidelines focus on the following five parameters.

Material Selection

Material characteristics play a crucial role in determining the suitable cutting process for a specific material. For example, aluminum is generally easier to cut than steel due to its relative strength and durability.

When selecting materials, manufacturability should also be considered. If both steel and aluminum can withstand the required operation's loads, it may not always be smarter to choose the stronger alternative (steel) without considering manufacturing capabilities.

Hole Diameter

When designing a product involving drilled holes in a sheet, it is important to consider the sheet's thickness and the diameter of the hole. A general rule of thumb is to ensure that the hole's diameter is at least equal to the overall sheet thickness.

If the hole diameter is too small compared to the sheet thickness, cracks and brittle areas may form around the hole. Over time, these cracks can propagate and result in durability issues that negatively affect the product's overall performance.

Therefore, it is essential to ensure that the hole diameter is appropriate for the sheet thickness, maintaining the structural integrity and long-term durability of the product.

Localized Hardening

During the cutting process, significant heat can be generated, affecting the material's properties. Overheating in the region surrounding the cut can lead to localized hardening. To prevent this issue, it is recommended to reduce the cutting speed and use coolants to regulate the temperature in the affected area. These measures minimize the risk of localized hardening.

Distortion

Distortion in sheet metal fabrication refers to the warping, bending, twisting, or buckling of the metal sheet during the manufacturing process. This issue can occur due to factors like temperature changes, stress, or pressure during fabrication. Distortion can cause significant problems in the final product, such as dimensional inaccuracies, poor fitment, and reduced strength.

To avoid distortion, several steps can be taken during sheet metal fabrication:

Kerf

The kerf is directly related to the width of the cutting tool and the material thickness being cut. It represents the width of material removed by the cutting tool and determines the amount of material wasted in the cutting process.

For example, if a laser beam has a kerf of 0.1mm and cuts through a 1mm thick sheet of metal, the total width of material removed will be 0.2mm (0.1mm from each side of the cut). The kerf width may vary based on the cutting process, material type, and thickness.

Considering the kerf is important when designing parts for sheet metal fabrication, as it can impact the final dimensions of the part. If precise dimensions are required, the designer should account for the kerf and adjust the design accordingly. Additionally, the kerf can also affect the cost of the fabrication process, as wider kerfs result in more wasted material.

Common Features in Sheet Metal Parts

Sheet metal parts often incorporate several common features to meet industry requirements. Here are the six main features commonly found in sheet metal parts:

| Parameters | Description | Recommendations |

|---|---|---|

| Corner Fillets | Corner fillets are rounded edges or corners on sheet metal parts that are created to avoid sharp edges, which can be dangerous and can also cause stress concentration in the metal, leading to failure. | Size: The size of the fillet should be at least equal to the thickness of the sheet metal. In other words, a 2mm fillet should be used for sheet metal that is 2mm thick or less. |

| Symmetry: The fillets on a part should be symmetrical. This means that the fillets on opposing corners should be the same size. | ||

| Uniformity: The fillets should be uniform in size throughout the part. This means that the fillets on all corners should be the same size. | ||

| Placement: Fillets should be placed in areas where stress concentrations are likely to occur. This includes areas where the sheet metal is bent or where there is a change in shape or direction. | ||

| Radius: The radius of the fillet should be as large as possible. This helps to distribute stress more evenly and reduces the likelihood of stress concentrations. | ||

| Design: The design of the part should be such that fillets can be easily added without compromising the integrity of the part. | ||

| Ribs | Raised features that are typically perpendicular to the surface of the sheet metal part. They are used to add strength and stiffness to the part without adding much weight. | Keep the rib thickness to no more than 60% of the sheet metal thickness to avoid creating stress concentrations. |

| Use fillets to smooth the transition between the rib and the surrounding material, which will help to distribute stresses more evenly. | ||

| Avoid placing ribs too close together or too close to bends, as this can create weak spots in the material. | ||

| Consider using tapered or variable-height ribs to distribute stresses more evenly. | ||

| Embossment | Recessed features that are typically parallel to the surface of the sheet metal part. They are used to add depth or texture to the part, or to create a space for another component to fit into. | Keep the depth of the embossment to no more than 50% of the sheet metal thickness to avoid creating stress concentrations. |

| Use fillets to smooth the transition between the embossment and the surrounding material, which will help to distribute stresses more evenly. | ||

| Avoid placing embossments too close together or too close to bends, as this can create weak spots in the material. | ||

| Consider the impact of the embossment on the overall appearance of the part, and make sure it is aligned with any branding or design requirements. | ||

| Round Boss | A raised circular feature in sheet metal fabrication that is used to add strength and rigidity to a part. It is typically created by punching or forming a circular depression in the sheet metal, which causes the metal around the perimeter of the depression to bulge out and form a raised circular feature. | Choose the right size and location: carefully consider the placement and size of the boss to ensure that it will provide the necessary support and strength without interfering with other components or creating manufacturing challenges. |

| Use the right tooling: Creating a round boss requires specialized tooling, such as a punch and die set or a forming tool. It’s important to use the right tooling for the job to ensure that the boss is formed correctly and that the sheet metal is not damaged in the process. | ||

| Consider material thickness: The thickness of the sheet metal will affect the size and shape of the round boss that can be formed. Thicker materials may require larger or deeper bosses to provide the necessary strength and rigidity. | ||

| Dimple Feature | Dimples are often used for a variety of reasons, including: To improve the stiffness and strength of a sheet metal part by adding reinforcement. To create a smooth and flush surface for fasteners or other components to be attached. To provide clearance for other parts or components. | Consider the size and location of the dimple carefully. Dimples should be placed in areas where they will provide the most benefit, and their size should be appropriate for the application. |

| Overly large or deep dimples can weaken the material, while too small or shallow dimples may not provide sufficient reinforcement. | ||

| Choose the right tool for the job. There are a variety of tools that can be used to create dimples, including punches, dies, and form tools. The tool you choose will depend on the size and shape of the dimple, as well as the type of material being used. | ||

| Take into account the thickness and material of the sheet metal. Different types of sheet metal may require different techniques or tools for creating dimples, and thicker materials may require more force or a larger tool. | ||

| Be aware of any limitations or restrictions in the design. Dimples can be useful features, but they may not be appropriate for every application. Make sure that the design takes into account any potential issues or challenges that may arise from adding dimples. | ||

| Louver Feature | The primary purpose of louvers is to improve the airflow and ventilation in the enclosure or panel that they are installed on. Louvers can be designed to fit a specific purpose, such as directing air in a particular direction, reducing noise, or providing protection against dust, dirt, or moisture. | Size: The size of the louvers should be carefully chosen based on the required airflow and the amount of space available for installation. Louvers that are too small may not provide enough ventilation, while those that are too large may compromise the structural integrity of the panel. |

| Orientation: The orientation of the louvers should be chosen based on the direction of airflow and the location of any potential obstructions or obstacles that could affect the flow of air. | ||

| Shape: The shape of the louvers can have an impact on the efficiency of the ventilation system. Louvers that are designed with a streamlined, aerodynamic shape can improve airflow and reduce turbulence. | ||

| Material: The material used for the louvers should be selected based on the intended application, as well as the environmental conditions the panel will be exposed to. For example, stainless steel or aluminum may be better suited for outdoor applications where exposure to the elements is a concern. | ||

| Manufacturing method: The manufacturing method used to create the louvers should be selected based on the desired precision, consistency, and cost-effectiveness of the fabrication process. | ||

| Round Knockout | Round knockouts can be used to create holes of various sizes, depending on the size of the punch and die used. They are commonly used in sheet metal fabrication for applications such as electrical boxes, HVAC systems, and enclosures. | Choose the right size: Make sure to use the correct size punch and die for the size of hole you need. Using the wrong size can result in a hole that is either too small or too large. |

| Use the right material: Round knockouts are typically designed to work with specific types of sheet metal, so make sure to use the appropriate knockout tool for the material you are working with. | ||

| Keep the punch and die sharp: Over time, the punch and die can become dull and start to deform, which can result in poor-quality holes. Keep them sharp and in good condition for best results. | ||

| Consider the thickness of the material: Round knockouts are best suited for thinner materials. If you need to create holes in thicker sheet metal, you may need to use a different tool or technique. | ||

| Be mindful of burrs: When using round knockouts, there is a risk of creating burrs around the edge of the hole. Make sure to remove any burrs with a deburring tool or sandpaper for a clean finish. |

Material Thickness

The recommended material thickness for sheet metal depends on the specific application and the chosen material. In general, thicker metals provide greater strength and durability, while thinner metals offer flexibility and lightweight properties. Typical thicknesses for sheet metal range from 0.5mm to 6mm, but they can vary based on the material and intended use. The following chart presents recommended material thicknesses for common metals used in sheet metal fabrication:

| Metal | Gauge | Millimeters | Inches |

|---|---|---|---|

| Steel/Stainless Steel/Aluminum | 22 | 0.8 | 0.031 |

| Steel/Stainless Steel/Aluminum | 20 | 1.0 | 0.039 |

| Steel/Stainless Steel/Aluminum | 18 | 1.2 | 0.047 |

| Steel/Stainless Steel/Aluminum | 16 | 1.6 | 0.063 |

| Steel/Stainless Steel/Aluminum | 14 | 2.0 | 0.079 |

| Steel/Stainless Steel/Aluminum | 12 | 2.5 | 0.098 |

| Steel/Stainless Steel/Aluminum | 10 | 3.2 | 0.126 |

Note: This chart provides general guidelines, and the appropriate material thickness for a given application may depend on additional factors.

Common Sheet Metal Design Mistakes to Avoid

Sheet metal fabrication is a complex process involving designing, cutting, bending, and assembling sheet metal into a final product. Even skilled designers can make mistakes that lead to costly rework or scrapped parts. To avoid these errors, it is crucial to be aware of the most common sheet metal fabrication design mistakes and take steps to prevent them.

Mistake 1: CAD File Without Bends

A common mistake to avoid is providing a CAD file without bends. A sheet metal part without bends cannot be fabricated as a single piece and may require additional parts and labor to join multiple pieces together. It is important to include bends in the design and specify the bend angles and radii to ensure correct manufacturability.

Mistake 2: Features Too Close to Bends

Another mistake is placing features such as holes, tabs, etc., too close to bends. This can result in deformed metal parts that waste time and money. To prevent this mistake, adhere to the 4T rule in all CAD designs. The 4T rule states that all features should be at least four times the material thickness away from any bend line.

Mistake 3: Perfectly Perpendicular Internal Bend Radius

Attempting to achieve a perfectly sharp corner in a sheet metal bend can lead to material deformation and cracking, compromising the final product's integrity. Specify a minimum bend radius appropriate for the material and thickness used to ensure a smooth transition in the bend and prevent stress concentrations that could result in failure. The bend radius can be determined by measuring the length of the bent area and dividing it by two. Using the same radius for all bends is more cost-effective than using different radii for each bend.

Mistake 4: Not Including Hardware Details in CAD File

It is best to include as many details as possible in the CAD file, including specific hardware specifications, sizes, and locations. This ensures a smoother fabrication process and a more accurate final product. For example, failing to include necessary hardware details may delay assembly time and increase costs.

Mistake 5: Choosing an Unsuitable Finish

Finishing is an essential step in the manufacturing process, and different finishes serve different functions beyond aesthetics. Some finishes offer protection against rust and corrosion. While others are solely for cosmetic purposes. Consider the specific requirements of your metal part and choose the appropriate finish accordingly. Understanding the appropriate finish for the intended application is crucial for achieving the desired functionality and appearance of the product.

Mistake 6: Selecting the Wrong Sheet Metal

Consider the application of the part throughout the design process. For example, using unfinished steel in a marine or salty environment would leave the metal parts vulnerable to rust and corrosion. Select the appropriate sheet metal by considering factors such as daily wear, environmental conditions, manufacturing capabilities, cosmetic appearance, required conductivity, and mechanical properties.

Mistake 7: Not Considering Material Strength for U Channels

U channels are critical components in many product designs, and their strength depends on the overall strength of the material. Neglecting to consider material strength can result in weak U channels that may bend or break under stress. To avoid this mistake, select the appropriate material and thickness for the U channel based on the expected load and any additional stresses the channel may experience.

Mistake 8: Designing Unachievable Welding Requirements

Consider welding or other mechanical joints in the design phase. Overestimating the welding capabilities can increase complexity and costs. Implement strict design for manufacturing (DFM) practices to ensure all features align with prevalent standards.

Types of Sheet Metals

Sheet metal refers to a wide range of metals used in fabrication. The most common types include:

- Stainless Steel: Known for its versatility, durability, and cost-effectiveness, stainless steel is widely used in various applications.

- Cold Rolled Steel: Suitable for applications where material strength is a primary concern.

- Pre-Plated Steel: Similar to regular steel, but with a special coating to prevent corrosion.

- Aluminum: Lightweight and inert, offering an excellent strength-to-weight ratio.

- Copper: Expensive but effective, resistant to chemical and biological degradation under normal conditions.

- Brass: An alloy of copper and zinc, known for its corrosion resistance and hardness.

Common Finishes for Sheet Metal Parts

While sheet metal often performs well without any additional processing, certain applications benefit from post-processing steps. Common finishes for sheet metal parts include:

- Anodizing

- Brushing

- Polishing

- Bead Blasting

- Powder Coating

- Plating

- Passivation

- Chrome Coating

- Custom Finishes Upon Request

KRRASS: Your One-Stop-Shop for All Sheet Metal Fabrication Equipment

The sheet metal fabrication design guide is made to introduce all the basic concepts of the process to anyone. It’s important for manufacturing partners to fulfill the varying requirements of the industry and comply with the ever-changing industrial standards.

KRRASS is an experienced sheet metal equipment manufacturing partner that can help you take your design from concept to technical production line. Whether you are a startup looking to bring a new product to market or an established company seeking to streamline your manufacturing processes, our team can provide the expertise and support you need.

At KRRASS, we understand the importance of manufacturability and how it can impact the success of your product. Our team of experts is equipped with the latest tools and technologies to provide a comprehensive design for manufacturing (DFM) analysis. We will work closely with you to optimize your sheet metal processing line and identify potential problems early to minimize the risk of production delays or quality issues.

Our manufacturing facilities are equipped with the latest equipment and technology. We can meet the needs of a variety of industries, including aerospace, automotive, medical, and consumer products.

When you partner with KRRASS, you can trust that your sheet metal fabrication equipment will be delivered on time, on budget, and with the highest quality standards. Contact us today to learn more about how we can help bring your design to life and accelerate your time to market.